China Best Prepainted Galvanized Steel Coil -CGCC

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

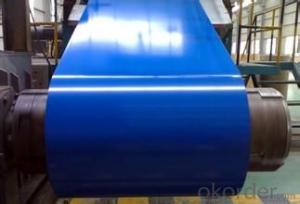

China Best Prepainted Galvanized Steel Coil -CGCC

1. Structure of China Best Prepainted Galvanized Steel Coil -CGCC:

Prepainted galvanized steel qualified with excellent decorative ,formability ,corrosion resistance ,coating adhesion ,can keep for a long time as well as maintain fresh color .For color coated steel sheet can obtain good economic benefit by steel belt wood ,efficient in construction and save energy ,prevent pollution etc. Which is an ideal material for manufacturing board.

2.Main Features of China Best Prepainted Galvanized Steel Coil -CGCC:

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

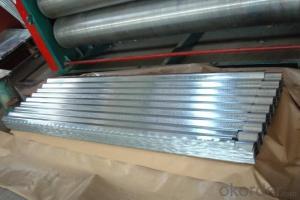

3.Prepainted Galvanized steel Coil Images

4.Prepainted Galvanized steel Coil Specification

Standard: ASTM, GB,JIS,JIS G3302 ASTM 755 EN10169

Grade: DX51D CGCC CS

Thickness: 0.18mm~1.2mm,

Width: 600-1250mm

Coil weight:3-12 MT

Coil ID:508/610mm

5.FAQ of China Best Prepainted Galvanized Steel Coil -CGCC

We have organized several common questions for our clients,may help you sincerely:

1.How do you control your quality

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2.How long we will receive the goods ?

After receiving your deposit or workable lc ,our normal shipment date is 15-20days,and it takes around 28 days to reach your port of destination. But is up to different destination

- Q: How do steel coils contribute to the renewable energy equipment industry?

- Steel coils play a crucial role in the renewable energy equipment industry by being a key component in the manufacturing of various renewable energy technologies. One of the primary applications of steel coils is in the production of wind turbines. The tower, nacelle, and rotor blades of wind turbines all require steel coils for their construction. In the manufacturing of wind turbine towers, steel coils are used to fabricate the structural components that provide stability and support to the turbine. These coils are typically rolled and welded together to form the tower, ensuring its strength and durability to withstand the forces exerted by the wind. Additionally, steel coils are also used to produce the nacelle, which houses the generator and other essential components of the wind turbine. Moreover, steel coils are used in the production of rotor blades for wind turbines. These blades are responsible for capturing the wind and converting it into rotational energy. Steel coils are used to create the internal structure of the blades, providing the necessary strength and rigidity to withstand the aerodynamic forces. The coils are often combined with composite materials to optimize the performance and efficiency of the blades. Apart from wind turbines, steel coils are also used in other renewable energy technologies such as solar panels. In the manufacturing of solar panels, steel coils are used to create the frames and supporting structures that hold the photovoltaic cells in place. These frames ensure the stability and longevity of the solar panels, allowing them to efficiently capture sunlight and convert it into electricity. Overall, steel coils are vital in the renewable energy equipment industry as they provide the necessary strength, durability, and structural support to various renewable energy technologies. By enabling the production of wind turbines, solar panels, and other renewable energy equipment, steel coils contribute to the expansion and development of the renewable energy sector, thereby advancing the global transition towards cleaner and more sustainable sources of energy.

- Q: did bible stated that steel is coming from outer space. i mean meteor rocks that enter our earth sistem contains the minerals iron.

- If you are using either an NAB or RSV translation of the Bible, steel is only mentioned once in the Bible. Compare Nahum 2:4 (NAB) and Sirach 31:26 (RSV). There is no reference of an outer space in the Bible. Furnace is mentioned in Sirach. It takes a lot of energy to mix Iron and Carbon to produce steel. The alloy can only be produced in the furnace at an extremely high temperature.

- Q: What are the common manufacturing defects in steel coils?

- There are several common manufacturing defects that can occur in steel coils, including surface imperfections such as scratches, pits, or dents, dimensional inconsistencies such as uneven thickness or width, edge defects like burrs or cracks, and internal defects such as inclusions or voids. These defects can impact the quality and performance of the steel coils, and manufacturers strive to minimize these issues through quality control measures and inspections.

- Q: What is the typical size and weight of a steel coil?

- The typical size and weight of a steel coil can vary depending on its intended use and industry standards. However, a common size for a steel coil is around 36 inches in width and weighs approximately 5 to 10 tons.

- Q: What are the different types of steel surface finishes for coils?

- There are several types of steel surface finishes for coils, including hot rolled, cold rolled, galvanized, coated, and pickled and oiled.

- Q: What are the common coil transportation options?

- The common coil transportation options include trucking, rail transportation, and shipping via barges or vessels.

- Q: I wanted to get a cheapo ring and I found one I like, but it's stainless steel. Is that bad? Will it get dull and tarnished fast?

- go with silver its cheap but not as bad as steel

- Q: How can steel coils be recycled?

- Steel coils can be recycled by first removing any non-steel materials attached to them, such as plastic or rubber. The coils are then shredded into smaller pieces and sent to a steel mill, where they are melted down and transformed into new steel products. This process helps conserve natural resources, reduces energy consumption, and minimizes waste.

- Q: How are steel coils coated to prevent corrosion?

- Steel coils are coated to prevent corrosion through a process known as galvanization. This involves applying a protective layer of zinc onto the surface of the steel coils. The zinc acts as a barrier, preventing the steel from coming into contact with moisture and oxygen, which are the main causes of corrosion. This coating not only provides excellent corrosion resistance but also enhances the durability and longevity of the steel coils.

- Q: I need details for steel column splices welded or bolted. References or autocad blocks will be very useful. Thank you very much!

- Boy oh boy, that request would open you up to a bunch of different types of files and drawings. There are so many different ways to make a column splice for structural steels. And they all would depend greatly on the loads that the joint will be subject too. You need to find a copy of the Manual of Steel Construction Ninth edition (or newer if its out, mine is the ninth), from the AISC 'American Institute of Steel Construction. This book will show you quite a few different connection options, welded and bolted. You will need to make drawings from the dimensions and details you see in the book. One other thing, you might try to find a manual for steel detailing, the seventh edition of the above book had a section to show detailing dimensions for different steel elements, dependant on the size and shape of the member itself.

Send your message to us

China Best Prepainted Galvanized Steel Coil -CGCC

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords