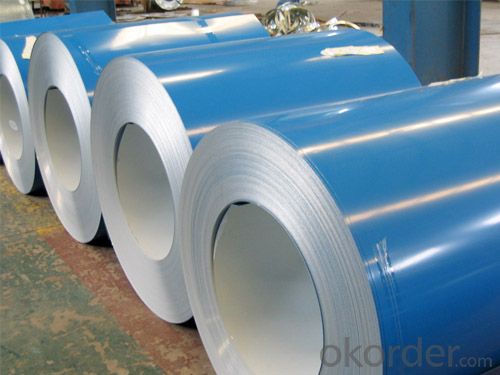

Pre-painted Galvanized/Aluzinc Steel Sheet Coil with P r ime Quality and Lowest Price Blue

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Pre-painted Galvanized/Aluzinc Steel Coil Description

With GI (aluzinc) as base metal, after pretreatment (degrease and chemical treatment) and liquid dope with several layers of color, Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance.

2.Main Features of the Pre-painted Galvanized/Aluzinc Steel Coil

• Excellent corrosion resistance

• Excellent weather resistance

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Pre-painted Galvanized/Aluzinc Steel Coil Images

4.Pre-painted Galvanized/Aluzinc Steel Coil Specification

8Zinc coating: 60-275G/M2, both sides

Weight per coil: 4-6 tons, also can be upon customer's requirements

Max loading weight in one 20ft container : 25 tons generally

Surface finish: with or without protect film

Quality standar: JIS G3312 CGCC & CGLCC

Hardness of P: Both soft and hard quality are available

Thickness : 0.14-1.20 mm

Paint thickness for top side : 5 micron primer + (10-20) microns modified polyester, any RAL color code.

Paint thickness for back side: (5-10) microns Epoxy

Width : 914mm, 1000mm, 1220mm and 1250mm, thickness 600-1250mm is available

Finish by coil or sheet: Both sheet and coil are available

5. FAQ of Pre-painted Galvanized/Aluzinc Steel Coil

We have organized several common questions for our clients,may help you sincerely:

How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: Ok I have a neodymium magnet, stuck to my fridge holding a old bottle cap opener for my beer it works fine. At the local rummage sale there was a beautiful cap opener my freind was selling for $0.25 she said had never beenUsed it was like 40 years old it is made a stainless steel. The magnet will not stick to it. I don't understand this looked this up and certain steels are not magnetic, I tried a experiment with my compass it don't point north as should it follows the bottle opener as I move it around it. If not magnetic why is this happening? Also tried placing near another neodymium magnet with a pull of about 200 lbs. Not I tiny bit of attraction to the metal. If so why is the tiny magnet in the compass attracted to it. But not a huge powerfull magnet.

- That's interesting that it caused deflection in the compass. A lot of stainless steels may be SLIGHTLY magnetic, because they have small amounts of ferrite or alpha-iron in them. Ferrite is one of the crystal phases of steel. It has a body-centered cubic (BCC) structure and it's responsible for the magnetism of ordinary steels. Adding certain elements like nickel, manganese, or molybdenum, changes the crystal structure of the steel to a face-centered cubic (FCC) structure, which is NOT magnetic. This crystal phase is known as Austenite or gamma-iron. However most iron alloys contain some impurities that may cause the steel to be not completely transformed into the FCC austenite phase, small areas remain as ferrite.

- Q: Is the product of mild steel environmentally friendly? does it produce any emissions?The same question for leather aswell.

- Steel just rusts, it doesn't produce any emissions just sitting there. They even make architectural steel called Corten to rust to a nice patina. If you consider how the steel was made in the first place, a great big NO! Steel making requires massive amounts of electricity plus it gives off some nasty fumes in the liquid state. Leather itself doesn't emit much of anything, but the dyes might. Again though, if you look at how it's made, tanning leather is right up there with steel mills and paper mills for pollution, some of the worst.

- Q: How are steel coils used in the production of rail tracks?

- Steel coils are used in the production of rail tracks as they are a primary raw material for manufacturing the rails. These coils are first processed to form the desired shape and dimensions of the rail tracks, which are then cut, welded, and shaped to create the individual rail sections. The steel coils provide the strength, durability, and flexibility necessary for the tracks to withstand heavy loads, extreme weather conditions, and constant use.

- Q: hi, i have a steel block with an unussual composition. does anyone know if this is any particular type?c- .6%, si - .33%, mn - .6%, sulphur - .014%, phosphorous - .013%, ni - 1.69%, Cr, 1.07%, molybdenum - .67%

- You have opened a can of worms. Specific types of steel vary not only by composition but by the way they were made, their physical properties and their morphology (microscopic structure). The composition you have given would fit for High Carbon Steel and Medium Carbon Steel. Go to the reference I've given, it allows you to put in 3 of the components of your alloy and then it gives you a list of possibilities. You can open each candidate individually and see the full composition. Hours of fun. :)

- Q: Can steel coils be customized according to specific requirements?

- Yes, steel coils can indeed be customized according to specific requirements. Customization can include adjusting the size, shape, thickness, and even the chemical composition of the steel coils to meet the specific needs and preferences of customers.

- Q: I know that it is used for katanas and swords but what is it and is it good i am pretty sure that it is the process of the steel but can I have a little more information.

- It's a special type of steel that was made in Syria. It is used to make swords or knives. It's mostly used in Middle East and South Asia.

- Q: Are steel coils used in the oil and gas industry?

- Yes, steel coils are commonly used in the oil and gas industry for various applications such as pipeline construction, storage tanks, and drilling equipment. The strength, durability, and corrosion resistance of steel make it an ideal material for handling the demanding conditions in this industry.

- Q: How are steel coils used in the production of elevator components?

- Steel coils are used in the production of elevator components to manufacture various structural and mechanical parts. These coils are typically formed, shaped, and cut to create components such as elevator guide rails, brackets, frames, and support structures. The high strength and durability of steel make it an ideal material for these components, ensuring the safety and reliability of elevators.

- Q: okay i got some questions of the steel plow.1st - who inveneted it? where and when?2nd - how did it work? what is it used for? what is it made of? how is it produced?okay guys thank you very much. remember best answer gets best answer 10 points!

- If you're willing to substitute the word iron for steel (steel came a good bit later in history), the Girard plow from the 1300's in Belgium would be the first example known. It's named after the guy who invented it (Girard). How did it work? Like any other plow! You drag it along and it makes a trench of sorts in the ground! It was used for agricultural purposes. As for how it was produced, you need to look up the history of the Iron Age to understand how they started to use iron back in about 1200BC to make tools.

- Q: Steel, Sturm, and Kitiara are in a series called the Dragonlance Chronicles.

- Steel Brightblade

Send your message to us

Pre-painted Galvanized/Aluzinc Steel Sheet Coil with P r ime Quality and Lowest Price Blue

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords