Pre-painted Aluzinc Steel Coils with Best Quality Competitive Price in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Aapplication of Galvanized steel coil

Galvanized steel coil is a special type of steel coil used in a number of different applications within fabrication and manufacturing environments. Steel coil of any kind is flat stock that is thin enough to be rolled into a coil or wound into a continuous roll. It is also able to be rolled out flat and cut at any length or shape needed. Having the steel coil galvanized helps the user by allowing it to be applied in outdoor fabrication projects.

2.Advantage of Our Organization:

We specialize in this field in China concerning GI, GL, PPGI, PPGL, Corrugated Steel sheet, we know the suppliers, the price, the domestic market and the price trend very well, we have sufficient information about various stocks, diffrient price, we update these information everyday.

3.Details of Galvanized steel coil:

Standard | ASTM,GB,JIS |

Grade | DX51D+Z,SGCC |

Thickness | 0.1-1.5MM |

Width | 914,1000,1219,1250MM |

Coil weight | 3-6mts |

Top paint | 22MIL |

Back paint | 11MIL |

Surface treatment | color coated/galvanized/galvalume |

Delivery time | 10-20 working days |

Packing : | waterproof paper, galvanized steel covered and steel strip packed |

USeage | widely used in construction,home,appliance,decoration,wear resistant steel,etc |

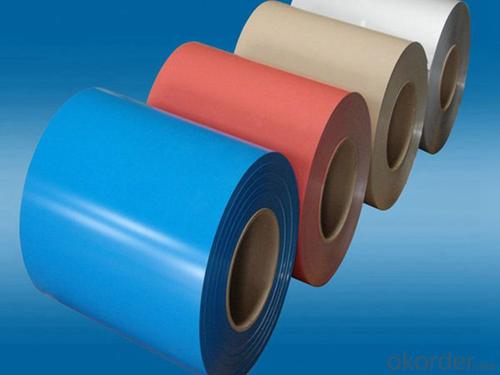

4.Galvanized steel coil images:

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of steel coils in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: I understand that damascus sword steel was made by folding the strip of steele double , reheating, hammering, folding again and so forth hundreds of times. Was this the same or very nearly the same techmique the japs used making the sword blades the samari swords?(forgive the misspelling)

- Folded Damascus Steel

- Q: I have heard using the BRASS casing is the best thing for an AR-15? Should i just use Brass or Steel?

- Two reasonable answers here. But let me say this...I just don't like the idea of steel touching steel at a high rate of speed (like when it's being cycled in and out of the chamber of a rifle). I can't help but feel that some sort of erosion is going to occur to the chamber of the rifle - which obviously isn't a good thing. If it were me, I would stick with firing brass casings only. The only gun I would fire steel casings through would be a cheaper SKS

- Q: How do you calculate the weight of a steel coil?

- To calculate the weight of a steel coil, you need to know the dimensions of the coil, specifically its length, width, and thickness. Then, you can use the density of steel (usually around 7850 kg/m³) and the formula: weight = length x width x thickness x density.

- Q: What are the challenges in coil recoiling?

- Coil recoiling, which is also known as coil winding, brings about a range of challenges that depend on the specific application and requirements. Some of the common hurdles encountered in coil recoiling are as follows: 1. Precision and accuracy: Achieving precise and accurate winding is vital for optimal coil performance. It is crucial to maintain consistent tension throughout the winding process, ensure proper alignment, and control the speed in order to prevent variations in the electrical properties of the coil. 2. Wire management: Managing the wire during the recoiling process can be difficult. The wire may be fragile, prone to tangling, or have specific handling requirements, such as being sensitive to magnetic or thermal influences. Employing proper wire management techniques, such as tension control, wire guide systems, and spooling mechanisms, is necessary to prevent wire damage and ensure uniform winding. 3. Space limitations: In many cases, coils need to fit within specific space constraints. Designing and winding coils to fit compact spaces can be challenging, particularly when considering the required number of turns, wire size, insulation, and any additional components or structures that may need to be incorporated. 4. Material selection: The selection of the appropriate wire and insulation material is crucial for optimal coil performance and durability. Factors such as electrical conductivity, thermal properties, mechanical strength, and chemical resistance must be taken into account to ensure that the coil can withstand the operating conditions and environmental factors it will encounter. 5. Heat dissipation: Coils often generate heat during operation, especially in high-power applications. Efficient heat dissipation is crucial to prevent overheating and ensure the longevity of the coil. Techniques such as designing the coil with proper ventilation, utilizing cooling mechanisms, or incorporating heat sinks are employed to address this challenge. 6. Quality control: Ensuring consistent quality in coil recoiling can be challenging due to factors such as variations in wire properties, operator skill, equipment calibration, and environmental conditions. Robust quality control measures, such as conducting regular inspections, performing electrical tests, and monitoring process parameters, need to be implemented to maintain consistent coil performance. In summary, coil recoiling demands meticulous attention, precision, and adherence to specific requirements in order to overcome the challenges and produce high-quality coils that meet the desired performance criteria.

- Q: Fallout 3 take it back quest?if i am in the rotunda and dont have broken steel installed yet so i cant leave if i instal it will i be able to continue the game even if im seconds away from the end without it Additional Detailsi know it continues on but im not sure if it will let me cause i got this far without it 1 objective away from finishing the quest idk if it will change that little bit so i can continue (ps3)already in the purifier place kill col. autum liek i said just gotta do the code thing to it idk if im to far for broken steel to effect this save file

- Yes. The Broken Steel add-on goes automatically where ever you are. The thing is, I would like stand around the control room for a little while until the Broken Steel add-on is completely downloaded (Basically pop A LOT of rad-x and radaway). You should see a pop-up message saying that Broken Steel is installed and the level cap is now at 30.

- Q: What is the major disadvantage of hardened steel? Do you think this form of iron would be wear resistant and retain a sharpened edge?

- The major disadvantage of hardened steel is that it is very brittle unless it is tempered. Hardened steel would be wear resistant, and would hold an edge as long as you don't cut anything harder than a boiled egg - the impact of the knife on a cutting board would shatter it.

- Q: is cold roll or hot roll mill roller is cast steel? or cast iron?

- Casting is a process of forming a part just like forging or rolling are also processes of forming steel. Cast steel can be any grade of steel poured into a sand mold to form a part like a water pump housing in your car. To be classified as steel, the mixture usually contains less than 2% carbon. Cast iron is a mixture that generally contains more than 2% carbon. It also can be poured into a sand mold. There are many grades of iron. Many metals can be cast into shapes like the air intake plenum on your car is probably cast aluminum. Bronze statues are made by pouring molten bronze into a mold. The process used to create a part has an effect of that part's mechanical properties. A casting is weaker than a forging but certain parts cannot be formed by forging. The large diameter rolls used in steel mills to roll steel into thinner plates or sheets is a hot rolled steel that has probably been forged into shape then machined into the final diameter. Some rolls are fabricated from hot rolled steel plates into shape. This allows the ability to add internal cooling paths to keep the roll from overheating.

- Q: What are the different methods of leveling steel coils?

- There are several methods of leveling steel coils, including roller leveling, stretcher leveling, and tension leveling. Roller leveling uses a series of rollers to gradually bend the steel to achieve a flat surface. Stretcher leveling involves stretching the steel through hydraulic or mechanical means to remove any residual stresses and straighten it. Tension leveling applies tension to the steel coil while passing it through a series of rollers, effectively elongating the material to remove any waviness or curvature.

- Q: I have my grandpa's navy knife from ww2, a mk2 combat knife i think, and i was wondering what type of steel it is made of. I'm guessing it's a high carbon steel, i'd just like to know exactly what grade.

- I would get a 1095, serrated edge, tanto style, with either a good quality rubberized or bone handle.

- Q: How do steel coils contribute to strength and durability in manufacturing?

- Strength and durability in manufacturing are enhanced by steel coils in several ways. Firstly, steel possesses inherent strength due to its high tensile strength, enabling it to bear heavy loads and resist deformation. Coiling steel involves hot rolling or cold rolling, which further enhances its strength and durability. During hot rolling, steel is heated to high temperatures and passed through rollers to shape it into a coil. This process aligns the steel's grain structure, resulting in a more uniform material with reduced internal stresses. Consequently, it becomes stronger and more resilient, maintaining its structural integrity even during manufacturing processes like bending, stamping, and forming. In contrast, cold rolling involves passing steel through rollers at room temperature. This process not only increases strength and hardness but also improves the surface finish. Cold-rolled steel coils are known for their smooth and uniform appearance, making them ideal for applications where aesthetics are crucial. Moreover, steel coils can be coated with various protective layers to enhance durability. Coatings like zinc or polymer-based ones act as barriers against corrosion, moisture, and other environmental factors that can weaken the steel. By preventing rust and degradation, these coatings prolong the lifespan of steel coils and the products they are used in, making them more durable and cost-effective in the long term. In summary, steel coils contribute to strength and durability in manufacturing by providing a resilient material capable of withstanding heavy loads and resisting deformation. The hot rolling and cold rolling processes further enhance the steel's strength and uniformity, while protective coatings prevent corrosion and extend the coils' lifespan. Ultimately, steel coils are indispensable components in manufacturing, enhancing the strength and durability of a broad range of products.

Send your message to us

Pre-painted Aluzinc Steel Coils with Best Quality Competitive Price in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords