Pre-Painted Galvanized/Aluzinc Steel Coil--Chinese Best in Low Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

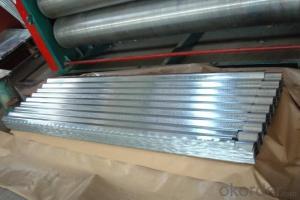

1. Pre-Painted Galvanized/Aluzinc Steel Coil--Chinese Best in Low Price

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features :

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• High strength

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

The Standard: AISI, ASTM, BS, DIN, GB, JIS

The Grade: DX51D, DX52D

The Thickness: 0.17-2.0mm

The Special Use: High-strength Steel Plate

The Width: 20-1250mm

The Length: customized

The Thickness: 0.13-4.0mm

The width: 20-1250mm

The zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

The color: all RAL color

The surface treatment: color coated

The coil weight: 4-7 tons

The coil ID: 508/610mm

The packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. How to guarantee the quality ?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: Is Carbon Steel strong for swords?

- Depends on the sword design. Some swords are high carbon, some a low carbon, some are made from a billet of alternating high and low carbon ('Damascus' steels). It all depends on what characteristics you want for your sword. Softer steels won't hold an edge as well but they offer great flexibility so your sword won't shatter when they make impact with armor or shields. Harder steels hold better edges but they're prone to binding in wooden shields and then being broken as soon as a bending force is applied along the weak axis of the blade. Japanese Katanas have both hard and soft steels to allow the blade to bend yet still hold strong edges. If you're making the sword from raw materials on your own, look up some different recipes for crucible steel. It's probably the most fun and involved process.

- Q: What is the role of steel coils in the manufacturing of pipes and tubes?

- Steel coils play a crucial role in the manufacturing of pipes and tubes as they serve as the primary raw material. These coils are unwound and then formed into the desired shape through various processes such as rolling, bending, and welding. The strength and durability of steel make it an ideal material for pipes and tubes, ensuring their ability to withstand high pressure, corrosion, and other demanding conditions.

- Q: How are steel coils used in the production of steel drums?

- Steel coils are used in the production of steel drums by being cut into sheets and then rolled into cylindrical shapes, which form the body of the drum. The coils provide the necessary strength and durability required for the drums to hold and transport various materials safely.

- Q: Can steel coils be perforated?

- Yes, steel coils can be perforated. Perforation is the process of creating small holes or punctures in a material, and steel coils can undergo this process to achieve specific purposes such as enhancing ventilation, improving drainage, or creating decorative patterns.

- Q: What are the different packaging options for steel coils?

- There are several packaging options for steel coils, including wooden crates, steel frames, and metal or plastic bands. These packaging options help to protect the coils during transportation and storage, ensuring their integrity and preventing damage.

- Q: How are steel coils processed into finished products?

- Steel coils are processed into finished products through a series of steps including uncoiling, leveling, cutting, shaping, and surface treatment. The uncoiling process involves unwinding the steel coil to create a flat sheet. Next, leveling machines remove any unevenness in the sheet's surface. Then, the sheet is cut into desired lengths or shapes using cutting machines. Shaping processes such as bending, rolling, or stamping are performed to achieve the desired product form. Finally, surface treatment techniques like galvanizing, painting, or coating are applied to enhance the product's durability and appearance.

- Q: What are the common thicknesses available for steel coils?

- The common thicknesses available for steel coils depend on the specific requirements and applications. However, there are some standard thicknesses that are commonly produced and used in various industries. Generally, steel coils can have thicknesses ranging from 0.005 inches to 0.5 inches or even more, depending on the type of steel and its intended use. For example, in automotive manufacturing, where steel coils are used for body panels and structural components, the common thicknesses can range from 0.5 mm (0.020 inches) to 3 mm (0.118 inches). In the construction industry, where steel coils are utilized for roofing, siding, and structural framing, the common thicknesses can vary from 0.014 inches to 0.062 inches, depending on the specific application and structural requirements. Similarly, in the manufacturing of appliances, such as refrigerators, washing machines, or HVAC systems, steel coils with thicknesses ranging from 0.018 inches to 0.035 inches are frequently used. It is worth noting that these are just some of the common thicknesses, and there can be variations based on the specific requirements of different industries and applications. Additionally, custom thicknesses can also be produced upon request to meet unique needs in various sectors.

- Q: will peircers use surgical steel? how do you know for sure what they are using?

- When you go to get your tongue pierced they will tell you exactly what their doing and what their using. And I had my belly button pierced, and my boyfriend has his tongue and eye brow pierced and it's all done with surgical steel. Piercers wont use anything but that.

- Q: What are the different types of steel coil surface finishes?

- There exist various options for steel coil surface finishes, each possessing distinct characteristics and uses. Some of the most frequently seen types are as follows: 1. Hot rolled: Achieved by subjecting the steel to high temperatures, resulting in a rough and textured surface. Hot rolled steel coils are commonly employed in applications where aesthetics are not a priority, such as structural or industrial projects. 2. Cold rolled: In contrast to hot rolled steel, cold rolled steel coils are processed at lower temperatures, resulting in a smoother and more refined surface. This finish is suitable for applications where a clean and polished appearance is desired, such as automotive parts, appliances, and furniture. 3. Galvanized: These steel coils are coated with a layer of zinc to safeguard against corrosion. This finish provides excellent rust resistance and can be utilized in various outdoor applications, including roofing, fencing, and signage. 4. Stainless steel: Stainless steel coils possess a unique finish that is resistant to corrosion, staining, and rust. Due to this, they find great versatility and suitability across a wide range of applications, including kitchen appliances, medical equipment, and architectural projects. 5. Coated: Coated steel coils are treated with a protective layer of paint or other coatings to enhance durability and aesthetic appeal. This finish is commonly employed in the construction industry for applications such as roofing, siding, and garage doors. 6. Pre-painted: Before being formed into the final product, pre-painted steel coils are coated with a layer of paint or resin. This finish offers a wide range of colors and finishes, making it popular for applications such as building cladding, appliances, and automotive parts. In summary, the selection of a steel coil surface finish relies on the specific requirements of the project, including aesthetics, corrosion resistance, and durability. Each finish has its own advantages and disadvantages, and it is crucial to consider these factors when choosing the appropriate type of steel coil surface finish for a particular application.

- Q: What are the advantages of using steel coils in various industries?

- There are several advantages of using steel coils in various industries. Firstly, steel coils offer exceptional strength and durability, making them ideal for applications that require high load-bearing capacity and resistance to wear and tear. Secondly, steel coils can be easily shaped and molded into different forms, allowing for flexibility in design and manufacturing processes. Additionally, steel coils have excellent thermal conductivity, which makes them suitable for applications that involve heat transfer. Moreover, steel coils provide corrosion resistance, ensuring longevity and minimal maintenance requirements. Lastly, steel coils are readily available and cost-effective, making them a cost-efficient choice for industries seeking reliable and versatile material solutions.

Send your message to us

Pre-Painted Galvanized/Aluzinc Steel Coil--Chinese Best in Low Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords