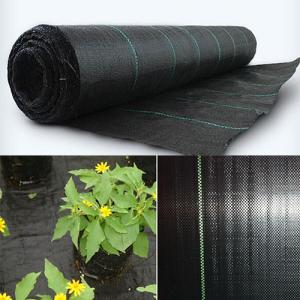

PP Weed Mat/Anti Weed Mat/Weed Barrier Fabric

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Introduction of Anti Weed Mat

Weed block landscape fabric not only prevents weeds,it encourage root growing by keep soil moist and cool.Made of UVtreated polypropylene,this costeffective weed control fabric feteures allow the free flow of air, water and nutrients to the soil while blocking sunlight and weeds.

Weed block helps minimize your yard work since it stops weeds from growing .You do not have to use

herbicides,which can damage your lawn and cause harm to children and animals.Made of polypropylenematerial ,weed block is easily cut to fit in your garden or hard landscape areas.

2. Technical Data Sheet of Anti Weed Mat

Norms | Weight(ASTM D 3776:2009):g/m2 | 120 | 140 | 160 | 170 | |

Tensile strength(ASTM D 4632:2008,C.R.E,grab method:N(lbf)) | Warp | 370(83) | 490(110) | 500(112) | 505(113) | |

Weft | 249(56) | 320(70) | 290(65) | 335(75) | ||

Elongation (ASTM D 4632:2008 C.R.E grab method 100%) | Warp | 7.3 | 11 | 9.9 | 13.9 | |

Weft | 5.7 | 7 | 7.4 | 9.1 | ||

Tearing strength(ASTM D 4533:2011 C.R.E, Trapezoid method:N(lbf)) | 120(27) | 140(31)

| 150(34) | 170(38) | ||

98(22) | 110(25) | 110(25) | 155(35) | |||

Bursting strength ASTM D 3786:2009,Hydraulic method:KPa(psi) | 923(134) | 1480(215) | 1280(186) | 1590(159) | ||

Puncture resistance ASTM D 4833:2007,C.R.E,N(lbf) | 230(52) | 275(60 | ||||

3. Function of Anti Weed Mat

Chemical free

Effective weed control

Allow air ,water and nutrients to reach the soil and the plant roots

Very resistant to puncture

Easy to install

Raise quantity and quality of crops

4. Application of Anti Weed Mat

1). Weed block for landscaped garden beds

2). Permeable liners for planters (stops soil erosion)

3). Weed control under wooden decking

4). Geotextile for separating aggregate / soils under walkway blocks or bricks

5). Assists in preventing paving from settling unevenly

6). Landscape fabric prevents soil erosion

5. Product photo of PP Woven Geotextile

- Q: How are geotextile mats used in erosion control on slopes?

- Geotextile mats are used in erosion control on slopes by providing stability and reinforcement to the soil. These mats are placed on the slope surface and serve as a barrier that prevents the soil from being washed away by rainfall or surface runoff. The mats also allow water to pass through, which helps in maintaining proper drainage and reducing the risk of slope failure. Additionally, geotextile mats promote vegetation growth by acting as a protective layer, allowing plants to establish their roots and further strengthen the slope against erosion.

- Q: Are earthwork products resistant to graffiti?

- Yes, earthwork products are typically resistant to graffiti due to their natural texture and composition.

- Q: Are earthwork products suitable for use in coastal erosion control?

- Yes, earthwork products are suitable for use in coastal erosion control. These products, such as geotextiles, geogrids, and gabions, can effectively stabilize soil, prevent erosion, and protect coastal areas from the destructive forces of waves and currents. They are commonly used in the construction of revetments, seawalls, and other erosion control structures.

- Q: What are the benefits of using geotextile mats in roadway reinforcement systems?

- Geotextile mats offer numerous benefits in roadway reinforcement systems. Firstly, they improve the stability and load-bearing capacity of the road by distributing the applied loads more evenly. This helps prevent rutting, potholes, and structural failures. Secondly, geotextile mats act as a barrier, preventing the mixing of base materials and subgrade soils, which reduces the risk of contamination and erosion. Additionally, these mats enhance drainage by allowing the passage of water while preventing the loss of fine particles. This helps to maintain the road's structural integrity and prevent water-related damages. Lastly, geotextile mats are cost-effective as they require minimal maintenance and prolong the lifespan of the roadway, reducing the need for frequent repairs and replacements.

- Q: What is the purpose of using geotextile bags in streambank protection?

- The purpose of using geotextile bags in streambank protection is to prevent soil erosion and stabilize the streambank. These bags act as a barrier against the flow of water, while still allowing water to pass through, reducing the force of the water and preventing further degradation of the streambank. Additionally, geotextile bags provide structural support, preventing the collapse of the streambank and protecting it from damage caused by natural elements.

- Q: How do geosynthetic liners help in preventing contaminant leakage?

- Geosynthetic liners are an effective solution for preventing contaminant leakage due to their impermeable nature. These liners act as a barrier, preventing the migration of pollutants and hazardous substances into the surrounding environment. By creating a sealed containment system, geosynthetic liners ensure that contaminants, such as chemicals, waste, and liquids, are securely contained, reducing the risk of contamination to soil, groundwater, and nearby ecosystems.

- Q: What are the advantages of using geosynthetic liners in secondary containment systems?

- Geosynthetic liners offer several advantages in secondary containment systems. Firstly, they provide a strong barrier against leaks and spills, reducing the risk of environmental contamination. They are also highly resistant to chemical degradation, ensuring long-term durability. Additionally, geosynthetic liners are flexible and easy to install, allowing for efficient construction and customization to fit various site requirements. Furthermore, they offer superior puncture resistance and can withstand harsh weather conditions, making them reliable and suitable for diverse applications.

- Q: Can earthwork products be used for constructing sports fields?

- Yes, earthwork products can be used for constructing sports fields. Earthwork products such as soil, sand, and gravel can be used to prepare the ground, create proper drainage systems, and level the playing surface.

- Q: How are geotextile bags used in erosion control on riverbanks?

- Geotextile bags are commonly used in erosion control on riverbanks by acting as a protective barrier against soil erosion. These bags are typically filled with sand or soil and placed strategically along the riverbank to stabilize the soil and prevent it from being washed away by the force of the water. The geotextile fabric used in these bags allows water to pass through while retaining the soil, effectively reducing erosion and maintaining the stability of the riverbank.

- Q: How do erosion control blankets aid in revegetation efforts in earthwork applications?

- Erosion control blankets aid in revegetation efforts in earthwork applications by providing a protective layer on the soil surface. These blankets help to reduce the impact of raindrops and runoff, preventing soil erosion and promoting the establishment of vegetation. The blankets also act as a barrier against wind, sunlight, and temperature fluctuations, creating a favorable microclimate for seed germination and plant growth. Additionally, erosion control blankets help retain moisture in the soil, enhancing seedling survival rates and accelerating the overall revegetation process.

Send your message to us

PP Weed Mat/Anti Weed Mat/Weed Barrier Fabric

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords