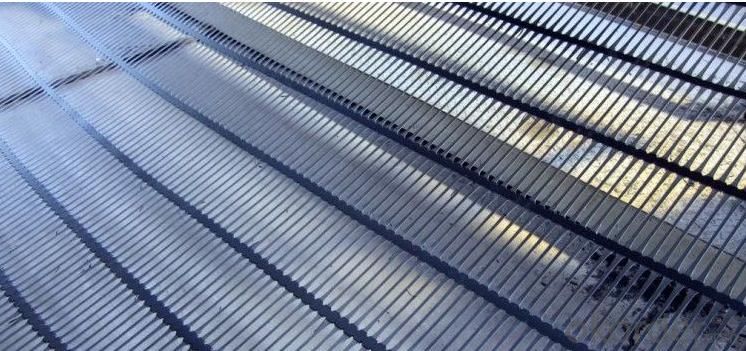

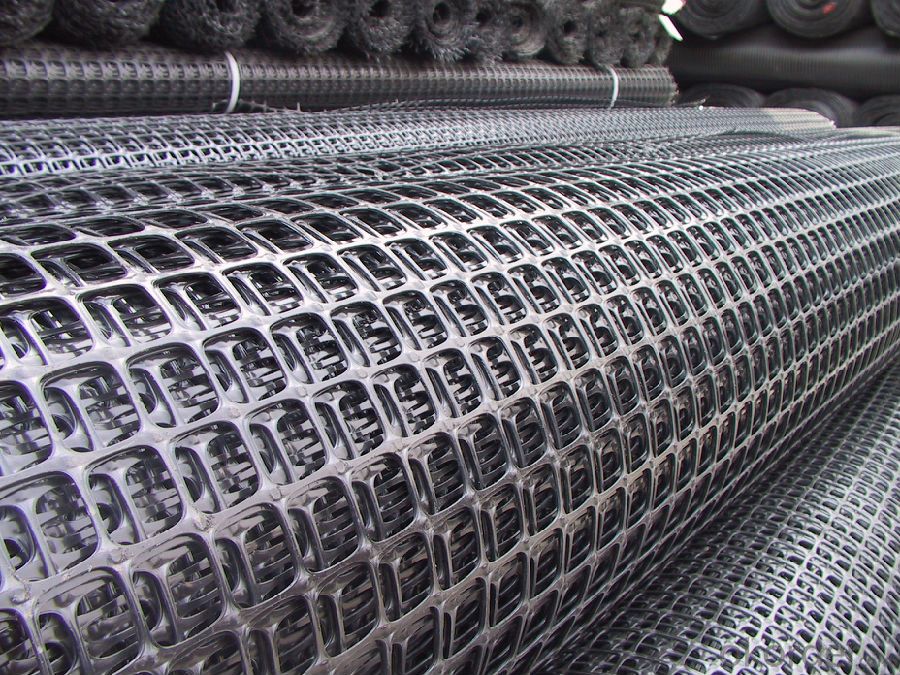

PP Uniaxial Geogrids / Polypropylene Uniaxial Geogrids

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

(ux) uniaxial geogrids

PP Uniaxial geogrid is expecially designed for soil reinforcement.it is sheet extruded,punched,heated and stretched from polypropylene,it has high tensile strength,excellent interlock capacity and deformation.

Speicification of PP Uniaxial Geogrid

| Property | TGDG | TGDG | TGDG | TGDG | TGDG | TGDG | |

| 35 | 50 | 80 | 100 | 110 | 120 | ||

| Ultimate tensile strength | kN/m | 35 | 50 | 80 | 100 | 110 | 120 |

| Elongation at maximum load | % | 10 | |||||

| Tensile strength at 2 % elongation | kN/m | 9 | 10 | 23 | 29 | 30 | 35 |

| Tensile strength at 5 % elongation | kN/m | 18 | 25 | 44 | 55 | 58 | 65 |

| Creep Limit Strength | KN/m | 15 | 21 | 30 | 39 | 40 | 46 |

| Minimum Carbon Black | % | 2 | |||||

| Property | TGDG 150 | TGDG | TGDG | TGDG | TGDG | TGDG | |

| 170 | 200 | 220 | 240 | 300 | |||

| Ultimate tensile strength | kN/m | 150 | 170 | 200 | 220 | 240 | 300 |

| Elongation at maximum load | % | 10 | |||||

| Tensile strength at 2 % elongation | kN/m | 39 | 45 | 55 | 59 | 65 | 90 |

| Tensile strength at 5 % elongation | kN/m | 77 | 90 | 110 | 120 | 132 | 182 |

| Creep Limit Strength | KN/m | 49 | 57 | 64 | 71.5 | 79 | 100 |

| Minimum Carbon Black | % | 2 | |||||

| Standard Roll Dimensions | |||||||

| Roll Length(m) | 50m | ||||||

| Roll Width(m) | 1m,2m,3m | ||||||

FAQ

1. How about the delivery time?

Lead time since receipt of 30% T/T deposit payment: 3 weeks.

2. What kind of payments does jenor support?

T/T, L/C, Cash are accepted.

3. What's are the MOQ?

We can according to your condition to set the MOQ.

And we can provide you samples for quality inspection.

4. Do you charge for the samples?

Accordeing to our company policy, the samples are freee, we only charge the freight fee. And we will return the freight fee If you set the order .

5. Can you produce the product according to customers' requirements ?

Sure, we are professional manufacturer, OEM and ODM are both welcome.

6. Can you tell me your main customers?

That's our customers' privacy, we should protect their information. At the same time, please rest assured that your information is also safe here.

- Q:Can geogrids be used in stabilization of canal banks?

- Yes, geogrids can be used in the stabilization of canal banks. Geogrids are commonly used in civil engineering projects to reinforce soil and provide stability. They can be installed along canal banks to increase their strength, prevent erosion, and enhance overall stability. Geogrids provide a cost-effective solution for long-term stability and can withstand various environmental conditions.

- Q:Can geogrids be used for reinforcement in landfill liners?

- Yes, geogrids can be used for reinforcement in landfill liners. Geogrids are commonly used in landfill engineering to improve the stability and strength of liners by providing reinforcement and preventing soil erosion. They help to distribute loads evenly, enhance long-term performance, and increase the overall stability of landfill liners.

- Q:Construction technology of steel plastic grille

- (4) the first layer of geogrid paved, began to fill with second layers of 0.2m in thick sand (coarse), the method of sand transport to the site: car unloading to the subgrade side, then put forward to push the bulldozer, within 2 meters on both sides of the subgrade filling after 0.1M, the first layer of geogrid fold up and then fill in 0.1 meters in the sand (coarse), from both sides to the middle filling and advance, prohibit all machinery without filling (coarse sand) of Geogrid on traffic operation, it can guarantee the geogrid is smooth, does not play drums, do not wrinkle, stay in the second layer (coarse) after the formation of sand, the level of measurement, to prevent uneven filling thickness, leveling and correct use of vibratory roller 25T static pressure two times.(5) as the second layer of geogrid layer construction method with the first method, and finally filling in 0.3m (coarse sand), filling in the same way as the first layer, using 25T hydrostatic roller two times, so subgrade reinforcement is dealt with.

- Q:Are geogrids suitable for use in seismic zones?

- Yes, geogrids are suitable for use in seismic zones. Geogrids are flexible and durable materials that can reinforce soil and improve its stability. In seismic zones, where the ground is prone to shaking and instability during earthquakes, geogrids can effectively enhance soil resistance to lateral movement, reduce soil liquefaction, and provide greater overall stability to structures. Their ability to distribute loads and increase soil confinement makes them highly suitable for use in seismic zones.

- Q:Can geogrids be used in soil reinforcement for landslide mitigation?

- Yes, geogrids can be used in soil reinforcement for landslide mitigation. Geogrids are commonly used in geotechnical engineering to reinforce soil and improve its stability. When placed within the soil, geogrids provide additional strength and prevent soil movement, thus reducing the risk of landslides.

- Q:Are geogrids suitable for use in soil reinforcement for coastal protection structures?

- Yes, geogrids are suitable for use in soil reinforcement for coastal protection structures. Geogrids are commonly used in such applications as they provide excellent reinforcement to the soil, improving its stability and resistance against erosion caused by waves and tides. They offer high tensile strength, durability, and resistance to harsh environmental conditions. Additionally, geogrids can be easily installed and integrated into various coastal protection systems, making them an effective solution for reinforcing soil in coastal areas.

- Q:Can geogrids be used in railway ballast reinforcement applications?

- Yes, geogrids can be used in railway ballast reinforcement applications. Geogrids provide effective reinforcement to the ballast layer, increasing its strength and stability. By distributing loads more evenly, geogrids help to reduce settlement and deformation, improving the overall performance and longevity of the railway track.

- Q:How do geogrids improve the performance of unpaved parking lots?

- Geogrids improve the performance of unpaved parking lots by providing reinforcement and stabilization to the soil, which helps to prevent the base material from shifting or rutting under the weight of vehicles. This increased stability reduces the need for frequent maintenance, extends the lifespan of the parking lot, and enhances its load-carrying capacity.

- Q:Geogrid manufacturers and the price is how much?

- Geogrid is made of polypropylene, PVC polymer and thermoplastic or molded by two-dimensional grid or a certain height of the three-dimensional mesh screen, when used as a civil engineering, called geogrid. Geogrid is divided into four categories: plastic geogrid, steel plastic geogrid, fiberglass geogrid and fiberglass polyester geogrid. Uniaxial Plastic Geogrid

- Q:Geogrid construction must be folded back 2m wrapped in compacted packing on it?

- Edit this section of geogrid construction notesPaved geogrid should be smooth, paving layer after acceptance, to prevent longitudinal askew phenomenon, according to the width of paving layer or draw white thread, you can start paving, and then use the end of the nail fixed grid (nail 8, per meter wide uniform fixed distance) well, after the end of the fixed grid, with the paving machine will grill slowly pulled forward each shop, shop 10 meters long artificial tightening and straightening once, until a volume grating puwan, put the next volume, operation with a roll of puwan with roller 6T-10T from the starting point to begin the direction of rolling over, (steel rolling as road paving in the surface layer and the leveling layer, the machine is appropriate; such as grid laid directly on the concrete pavement, with the roller roller is appropriate) ground shop: Volume long unit as the laying of the long, the grid should be covered the long shop Full, then the overall check a paving quality, and then paving the next section, the next section of paving, grille and grille can be used lap length 10-15CM, and fixed with nails or wedge to shop in second, to the direction followed by analogy with operating requirements.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PP Uniaxial Geogrids / Polypropylene Uniaxial Geogrids

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords