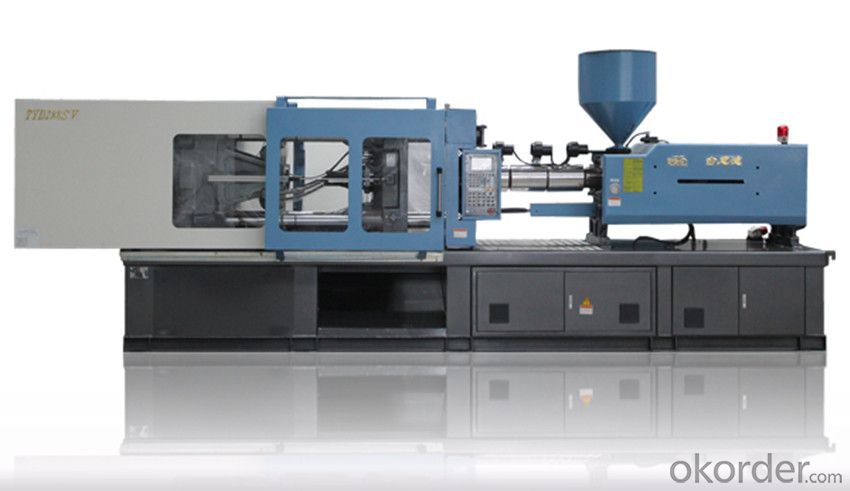

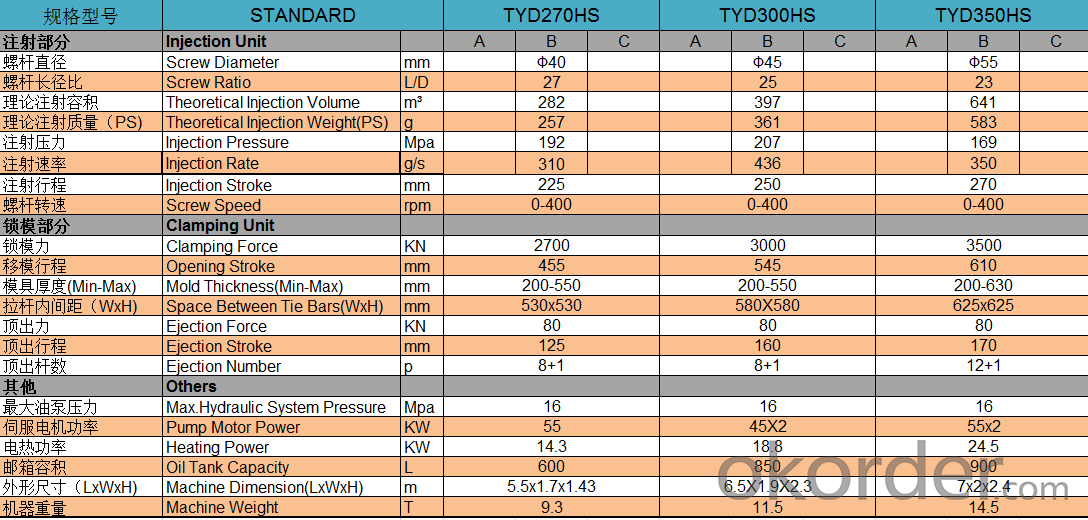

pp disposable food box plastic injection molding machine for thin wall products

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 40 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

THIN WALL PRODUCTS SPECIAL MACHINE

PP DISPOSABLE FOOD BOX

3 MACHINE WITH SPACIAL SCREWS for your reference

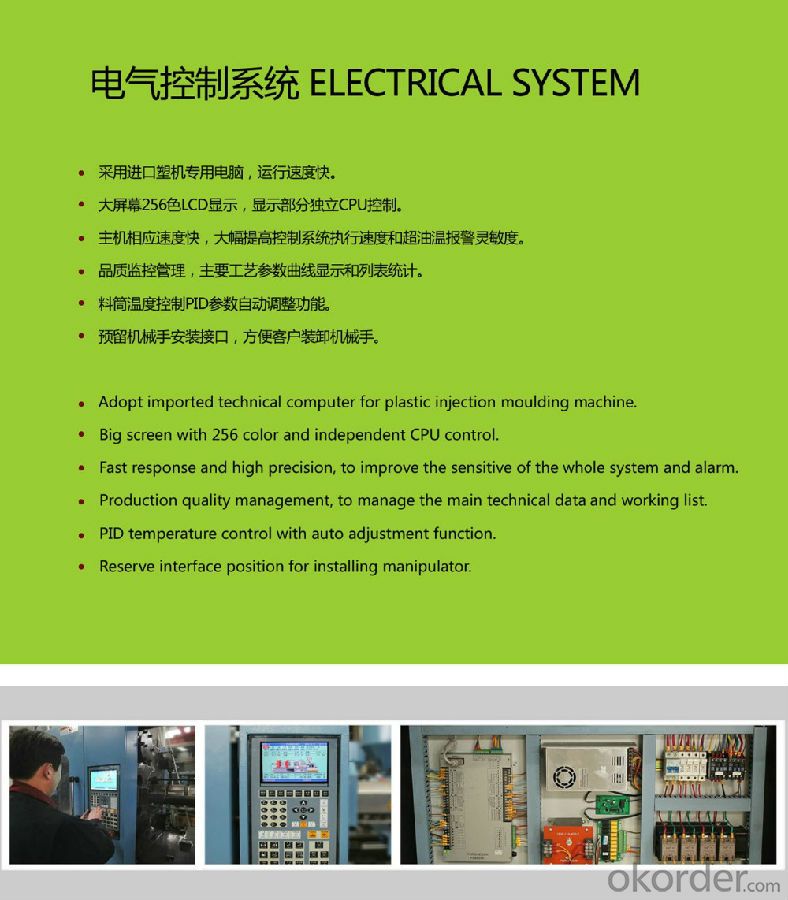

our technical advantage

our packing:

Fine package on pallet. In case of the size and weight requirment, it will be loaded in seperated containers.

Our Services

1. Our manufactory team will help you to choose the TYD machines to match your production demand

2. We apply the OEM service to meet your production requirment

3. Our after-sale service will help you to maintain the machine in proper condition

Company Information

our factory is one of the professional plastic injection molding machinery manufactury in China

The characteristics of the machines are high efficiency and energy saving, the spec are from 50 grams to 20000 grams.

We have 100 sales and service facilities were founded in China and overseas market.

Up to now, our products have sold in Brazil, Pakistan, Russia and other places.

We have passed the ISO 9001:2008 and CE certification.

The main parts of the machine come from Germany, Italy, Japan, Taiwan and other countries.

FAQ

Q. How to choose the TYD injection molding machine?

A. It based on the mold size and mold stroke according to products weight and dimension, wall thickness, properly clamping force and combined with the injection pressure. Our work team will help you to make the good choice if you can apply the products spec.

Q. Do you OEM?

A. Yes, our OEM team would like to work with you.

Q. where is your factory location?

A. we are located in Zhoushan seacost City which is near the Shanghai and Ningbo city. your are welcome to visit our factory.

- Q:Injection molding machine barrel, and the height of about how to adjust?

- The screw you're shooting is just adjusting the height and the left and right. If the deviation is large, the fixed seat, the piston rod, the pressure plate and the screw should be loosened.

- Q:Injection molding machine products shrink, how to solve?

- The working principle of injection molding machine and injection syringe with similar, it is the use of screw (or piston) thrust, the plasticizing good molten state (i.e. viscous flow) plastic injected into the mold cavity closed good after curing stereotypesmade the process of the products. Injection molding is a cycle process, each cycle mainly includes: quantitative feeding - melt plasticization - pressure injection - mold cooling - die opening pieces. Take out the plastic parts and then close the die for the next cycle. Action procedure: die, pre molding, pour, retract, nozzle (nozzle forward), injection, pressure protection, nozzle (back of nozzle), cooling, mold opening, ejecting, opening, taking the workpiece, closing the door, closing the mould, closing the mould, closing the mould, closing the door, closing the mould and closing the mould.Product shrinkage problem, if it does not involve other reasons, only injection molding process, the holding pressure is the most critical factor. Is the purpose of holding pressure when the screw after the injection, and exert a certain strength to the screw is held in place for a period of time, namely after injection and then squeeze some material into the cavity and prevent plastic reflux is not solidified completely to shrink. Keep the pressure big, the density of the plastic in the cavity is big, the surface is smooth and full. Shrinkage is positively related to size. Position, pressure, speed, the relationship between the three is connected, and in the adjustment of the machine should be based on the size of the product, the location of glue points, methods, raw materials, types and so on. For example, PC material, poor liquidity, injection molding must use high speed, high pressure, or easy to fight. And nylon or PP, the speed is too fast, the lack of mold exhaust, it is easy to generate coke.

- Q:What is I/O on an injection molding machine?

- The I/O is the input and output terminal definition and serial number of the injection molding machine

- Q:What are the features of servo motors for injection molding machines?

- Dongguan professional import servo motor maintenance professional encoder maintenance, including encoder, encoder, wear, scrap, technical transformation, encoder origin adjustment, magnet rupture, bearing damage, burning coil shaft fracture, etc.!The most professional and trusted servo motor repair terminal service provider in china!Global heat S line, Dongguan 135 deep, 2881 machines, 3210 electricity Mo workersBecause of concentration, so professional

- Q:The higher the screw speed of the injection molding machine, the higher the oil temperature

- The higher the screw speed of the injection machine, the higher the oil temperature, which is normal, because the screw will rotate continuously and friction of the material, friction will produce heat. We generally cold water machine injection molding machine can be equipped with a mechanical product in Europe, so can increase oil temperature control.

- Q:Advantages and disadvantages of horizontal injection molding machines and vertical injection molding machines?

- 1. horizontal machine has the advantages of high operation, convenience, high safety performance, large bearing size and so on. The disadvantage is that the floor space is large and the price is relatively high. Suitable for medium and large moulds.

- Q:Consult the injection machine and say how many grams, but I also see "360T 250T", what does this mean? Thank you

- Injection molding machine on the subject of its clamping force, the general 1T can be understood as 1 grams.

- Q:The proportion of each kind of introduction? Molding shrinkage? Molding temperature? Drying conditions? Overall performance? Mainly for use. I sell plastic parts and I want to make a wall calendar.

- you still go to find a professional book, check the good, this to make a mistake, lost your face.

- Q:General injection molding machine agents need what conditions?

- This is to ask manufacturers, each manufacturer of different

- Q:What's the meaning of "loosening and retreating" before injection machine?

- Small is relatively loose, loose retreat is to prevent the flow of material out of the back too much air inside, back too little will flow out, under the influence of the quality of the first mock exam.Injection molding machine, also known as injection molding machine or injection machine. It is a thermoplastic or thermosetting plastic plastic molding mold made of plastic products of all shapes of the main molding equipment. It is divided into vertical, horizontal and all electric type. The injection molding machine heats the plastic, applying high pressure to the molten plastic to make it crack and fill the mold cavity.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

pp disposable food box plastic injection molding machine for thin wall products

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 40 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords