Porcelain floor tile,ceramic tile,wall tile,full polished porcelain tile

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description of Porcelain floor tile,ceramic tile,wall tile,full polished porcelain tile

Ceramic tile, is a kind of refractory metal oxides and metal oxide, by grinding, mixing, pressing, glazing, the sintering process, it bcomes acid and alkali resistant porcelain or stone construction or decoration materials, such of these called ceramic tile. Its raw materials are mixture of clay, quartz sand and so on.

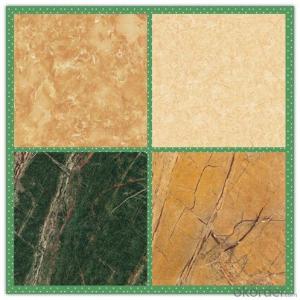

According to craft and characteristic, Ceramic tile can be divided into Glaze tile, Full body tile, polishing tile, Rustic tile, Vitrified tile and Mosaic etc. Different characteristics has its own best usage way.

2. Features of Porcelain floor tile,ceramic tile,wall tile,full polished porcelain tile

Glazed tile: refers to the brick burn with glaze layer surface. This kind of brick is divided into two categories: one is the use of clay firing; Another is made of porcelain clay fire, about 80% of the buyers choose it as ground decorates material.

Full body tile: this is a non-glazed porcelain tiles, has good skid resistance and abrasion resistance. Usually said "slippery prevented floor tile" were mostly body brick. Because the price moderate, it is quite popular with consumers.

Polished tile: it is polished, this kind of tilt is with high hardness, very wear-resisting.

Vitrified tile: it is made from high temperature. Vitrified tile is the most hard of all ceramic tile.

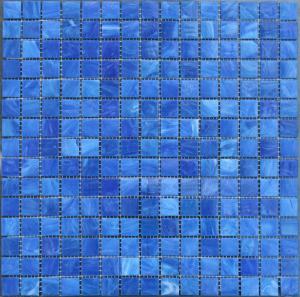

Ceramic Mosaic: also known as Mosaic, with more specifications, thin and small, hard, acid-proof, alkali resistance.

3. Specifications of Porcelain floor tile,ceramic tile,wall tile,full polished porcelain tile

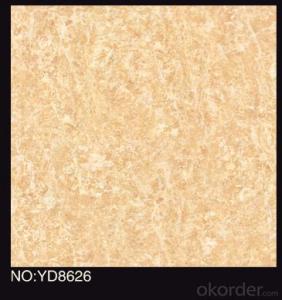

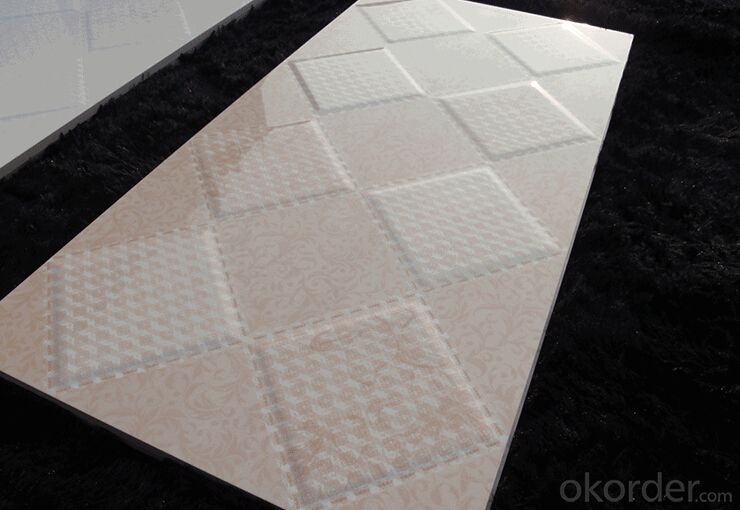

Porcelain floor tile,ceramic tile,wall tile,full polished porcelain tile

Sizes: 600 x 600, 800 x 800mm, many choices are available

Thicknesses: 9.3-9.5mm

Water absorption: 0.1%

Surface: smooth

Min. order quantity:500 SQM

Certificates: CE and ISO9001

Usage area: Be suitable for market, hospital, metro, school, office building, hotel, real estate, bar and living room etc.

Package: standard export paper carton with wooden pallet

Payment terms: T/T or irrevocable L/C at sight

Delivery time: With 20 days after deposit

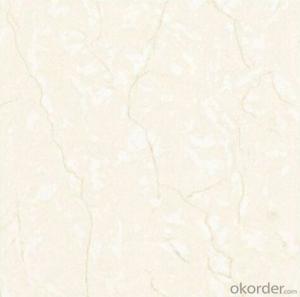

4. Images of Porcelain floor tile,ceramic tile,wall tile,full polished porcelain tile

5. FAQ

1) Where it could be applicated?

The living room, kitchen, bathroom, balcony wall ground and local background wall etc.

2) Are free samples available?.

Yes. But express delivery cost is to be collected and we will pay it back after confirming the order.

3) What about the lead time for mass production?

Honestly, it depends on the order quantity and the season you place the order. Generally speaking, we suggest that you start inquiry two months before the date you would like to

get the products at your country.

4) What is your terms of delivery?

We accept EXW, FOB, CIF, etc. You can choose the one which is the most convenient or cost effective for you.

- Q: I will be doing my first tile job soon. I will be removing/replacing the tile on my kitchen countertop. I have got most everything figured out with the exception of removing the existing tile on the backsplash. I believe the tile was placed directly over sheet rock (tract home). Any suggestions on how to remove the tile without too much damage to the sheetrock. If I have to do sheetrock replacement I don‘t think I could ever duplicate the texture now applied to the surronding sheet rock Thanks for any tips.

- Well you can use a hammer and a 1/2 chisel with safety glasses to start. As for sheetrock replacement...since it will be under the tile, the texture wont be seen and shouldnt be a problem. The coat that you will use to adhere the tile to the sheetrock will cover any inperfections caused by the tile removal. Are you talking about sheetrock or wonderboard?, sheetrock is also called drywall. If the base behind the tile is a hard ,cement based backing then just adhere the tile to that. I have never heard of anybody setting tile to sheetrock since it isnt waterproof. Good luck.

- Q: Trying to select floor tile to match kitchen and rest of downstairs living area (dining, living, family rooms). I have a lot of natural light in all areas. I have light oak kitchen cabinets. I just installed granite counter tops named Golden Desire but I have yet to install tile back splash. What color tile would I choose for the kitchen and throughout the living area. Thanks

- Take pieces of the things to which you are committed and get thee to a large tile store. Go for the match and also check for contrast. You may surprise yourself and like the unexpected. Think about your soft good (fabric items) as you will have to find compatible fabrics to make it all work together. Taking samples of everything is really important, as your eye will not recall the subtleties. No one can possibly give a color answer here, as there are an infinite number of possibilities within a single color, some of them correct, others very very jarring to the eye when it all comes together. If part of your question is whether to select the same tile for both areas, my suggestion is usually, YES, to avoid the appearance of a hodge podge patchwork quilt.

- Q: I need to remove several tiles for repair and replace the tiles with as little damage as possible

- if its in the middle, drill a hole in one, then chisel it out, once you have one removed the rest are easy

- Q: Would like to tile my bathroom floor. House is on a slab, bathroom has existing laminate flooring.1. Do I need to remove the laminate flooring or can I tile on top of it?2. Do I need to install a backer board first?3. Any tips I need when tiling around toilet plumbing and reinstalling the toilet?

- If tile is a self stick tile with a sheen then yes you must remove. Because you have a slab underneath, it would be best to use that as your substrate and can install tile directly over the slab. If you have a tile that needs to be waxed periodically, then you can take your chances with going directly over them. Ask at the floor store if there is an adhesive that will adhere to that particular type of tile. Do remove the toilet, and you will want to replace the wax ring as well. Take a picture with you of the floor to the floor store, good luck.

- Q: We have an installer, whom seems to be doing it wrong. I can‘t find any website that explains how to install tile the way he is doing it. Can you tell me if this sounds correct?First he puts mortar on the bare cement floor, then put down versa-bond or a bonding agent.. and then he puts more mortar on the tile and then lays it down.. Does this sound right to you?Thanks

- difficult situation look on to yahoo and bing just that could actually help

- Q: Tiles 1 open 2 What does it mean ah?

- Generally refers to cutting tiles such as the 800 * 800 cut into two 400 * 400.

- Q: I am installing 4.5 x 4.5 porcelain tiles on a drywall kitchen backsplash. Applying Omnigrip mastic using a 1/4 x 3/16 vnotch trowel. The tiles have a waffle grid pattern on the back which is about 1/16 deep. I tested the application of one tile and noticed that the mastic did not fill all the waffle depressions. Are they supposed to be all filled? DO I have to backbutter the tiles? Am I using the correct trowel size? Please help!P.S. What is the purpose of the waffle pattern in the first place?

- you must change your space for your kitchen space first

- Q: I have installed tile around my shower and and ready to fill in the gaps between the tile. Grouting looks messy and I don‘t know how to do it. Is there a grout that comes in a tube that can be put into a caulk gun? Can I just caulk the whole thing? This one is new to me so any help is appreciated!!!

- Grout is very easy to apply, especially if you use the tiny spacer blocks between the tiles to get the grout lines even. It is messy, but the extra wipes up cleanly with a sponge and water. Caulk is used between the bottom of the tile and the top of the tub because it's flexible and moves when the tub is filled. A solid hard grout line would break.

- Q: 80 cm x 80 cm tiles a piece of weight is probably how many kilograms?

- I sell tiles for 12 years, every day to calculate the fare to the driver, do not count me to him. We are all called

- Q: A week and a half a go I put eight 23 1/2‘‘ x 23 1/2 tiles on my sheetrock wall as a headboard and I can sometimes hear it crack! Will it fall?

- heck no! Ive seen tiles installed ritght onto sheet rock in wet arias as in bathroom shower! as far as the papper delamanating from the rock? hell no!!! ur good pal! If u hear cracking, Its not the tiles falling off. maybe the rock seperating from the studs, or the stus sressing out. think of it this way, when you go to hang a heany pic or mirror to the wall u usaly attach to the studs...what you could have done is reinforce the rock (add more screws) then did ur work. right now the rock should be attached with 1 1/4 screws at least with a nail pattern of 6 inch on perimiter and 12 inch in field. hope this info helps! I think ur good pal!

Send your message to us

Porcelain floor tile,ceramic tile,wall tile,full polished porcelain tile

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords