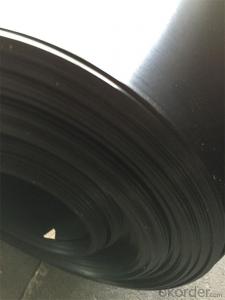

Epi Geomembrane - Polymer and Asphaltum EVA Adhesive Waterproofing Membrane Liner for Dam and Swimming Pool

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of self adhesive hdpe geomembrane sheet:

HDPE is a non polar thermoplastic plastic with high crystallinity and perfect electrical properties,especially the high insulation dielectric strengh.This polymer is non-hygroscopic which can be used to packing with good waterproof steam.HDPE with Middle to high molecure weight have good impact resistance at normal temperature even in the zero 40 degree Celisius.

Advantages of self adhesive hdpe geomembrane sheet:

high insulation dielectric strength

perfect impact resistance

good heat /cold endurance

no toxic

excellent chemical resistance

low water absorption

good temperature properties

great chemical stability

Parameter of HDPE

| density(g/cm3) | 0.91-0.95 | Brittle Temperature(°c) | <-120< span=""> |

| water absorption(%) | <0.01< span=""> | Linear expanding coefficient | 1213 |

| in-process shrinkage(%) | 1.55.5- | Thermal conductivity(W/(m.k)) | 0.44 |

| tensile strength(Mpa) | 21-37 | Volume resistivity(Ω.cm) | 61015 |

| breaking extension(%) | >880 | Dielectric constant(106HZ) | 2.34-2.35 |

| Bending strength(Mpa) | 11 | Dielectric dissipation factor | 0.0003 |

| compressive strength(Mpa) | 10 | Dieletcric strength/(Kv/mm) | >20 |

| impact strength(KJ/m²) | 4070 | Arc resistant/s | 115 |

| Rockwell Hardness | R70 | Oxygen index(%) | 20 |

| Heat formation temperature(°c) | 75 |

Packing and Delivery

| Packaging Details: | self adhesive hdpe geomembrane sheet packing: By pallets or according to your request |

| Delivery Detail: | 10-15days after your deposite |

FAQ

1Why use HDPE sheet?

HDPE Sheet has an almost waxy feel to it and is pretty good at being a low friction wear strip material and is used probably more than any other plastic as a wear strip on conveyors or production lines of huge companies.

2When can I get the HDPE price?

After getting your inquiry,the reply will be send to you in 8 hours at most.If you are urgent to get the price,pls call us or tell us in the email so that we will regard your inquiry priority.

3.How long can I expect to get the sample?

After learning all the requirments of the sample clearly,those itmes will be send to you via express which will take 3-5working days.You can use your own express account or prepay us if you do not have an account.

- Q: Which kind of film is preferable for bathroom?

- It is better to use explosion-proof film in the shower room. Sticking the film in the bathroom can reduce dazzle, outdoor ultraviolet light and heat.It is also able to protect the furniture and building materials in the bathroom and prevent 99% of the UV from going into the room.

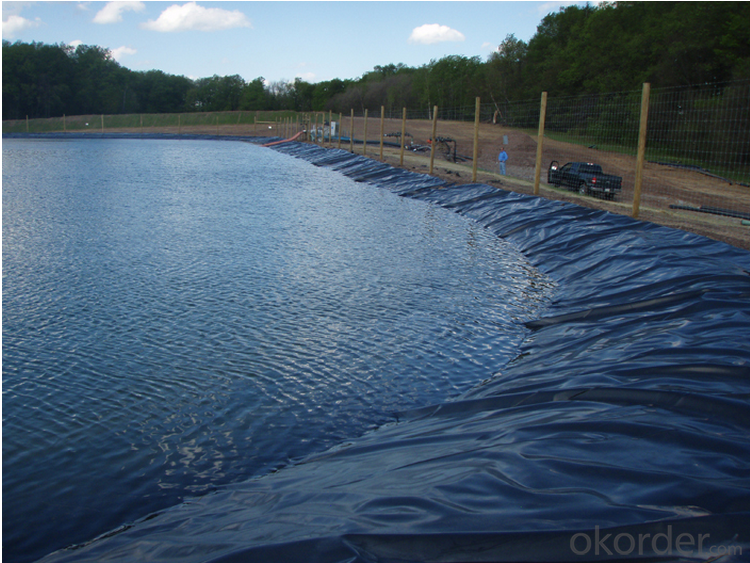

- Q: Can geomembranes be used in green infrastructure projects?

- Yes, geomembranes can be used in green infrastructure projects. They are often used as liners or barriers in various green infrastructure components such as rain gardens, bioretention basins, and green roofs. Geomembranes help to contain and control water flow, preventing seepage and protecting the underlying soil and vegetation. They can also be used in stormwater management systems to enhance water quality and reduce pollution. Overall, geomembranes play a crucial role in ensuring the effectiveness and longevity of green infrastructure projects.

- Q: How do geomembranes prevent gas leaks?

- Geomembranes prevent gas leaks by providing a barrier between the gas containment system and the surrounding environment. These impermeable synthetic membranes are designed to be highly resistant to the diffusion of gases, preventing their escape into the atmosphere. This helps to maintain the integrity of the gas storage or containment system and minimize the risk of leaks, thus ensuring safety and environmental protection.

- Q: Architectural glass film What are the benefits?

- 1, insulation to reduce cooling costs: summer LLumar film can effectively block 79% of the sun's heat, greatly reducing the solar energy into the room, thereby reducing the cost of cooling the building. 2, thermal insulation to reduce heating costs in winter: the low-emissivity (LOW-E) film attached to the inner surface of the ordinary single glazing can reduce heat loss by 30%, reduce indoor heat loss, reduce winter heating costs. 3, blocking 99% of harmful UV rays: ultraviolet in solar radiation is mainly responsible for the damage and color fading of carpet, furniture, art paintings, curtains and many chemical fiber textile and the skin cancer. Energy-saving insulation film can block 99% of UV rays. 4, to reduce the harsh glare and add comfort: direct light at the office table or relaxing at home will lead to tiredness, eye fatigue and distraction. LLumar is a direct installation in the surface of the glazing product, it helps correct light intensity area and back positive zone temperature uneveness and dispersed glare, uncomfortable glare, making employees more comfortable interior, more efficient. 5, the formation of absolute privacy: mount LLumar reflective film may be formed absolute privacy, it can avoid the window watching, protection of private property is not exposed to activities and infringement. 6, improve safety explosion-proof performance: bonding together LLuamr armored dragon film can effectively break the glass, to reduce industrial accidents, earthquakes, typhoons, terrorism, wanton destruction, and property damage caused by theft and other acts against the people.

- Q: How to determine the soil moisture content?

- To estimate the best water content of soil, and then from the best in order to two points each with two groups, the water content in turn decreased by about 2%.

- Q: Are geomembranes suitable for use in coastal areas?

- Yes, geomembranes are suitable for use in coastal areas. They are commonly used in coastal engineering projects to provide effective barriers against erosion, prevent water infiltration, and protect coastal structures. Geomembranes offer excellent durability, resistance to saltwater, and can withstand harsh environmental conditions, making them a reliable choice for coastal applications.

- Q: Are geomembranes resistant to UV rays?

- Yes, geomembranes are generally resistant to UV rays. They are designed to withstand prolonged exposure to sunlight without degrading or undergoing significant damage.

- Q: what's the function of paving composite geo-membrane in fishpond?

- seepage-proof and water conservation

- Q: the specification of composite geo-membrane

- composite geo-membrane (composite seepage-proof film) is divided into one cloth and one membrane and two cloths one film, width 4-6m, weight 200- , 1500g/ square meter, pulling-resistance, tear-resistance, bursting and other high physic mechanics performance indicator, the products is high strength, and has good extensibility, large deformation modulus, acid and alkali resistance, errosion resistance, aging-resistance, seepage-proof and other characteristics. it will satisfy the seepage-proof, isolation, reinforce, anti-cracking and other soil engineering demands in water?conservancy, municipal, buildings, transport, metro, tunnel, and engineer construction. Because it has selected polymer materials and the production process is added with anti-aging agent, it can be used in unconventional temperature environment. it's commonly used in the seepage-proof treatment of dams, drainage ditch, and pollution prevention treatment of waste storage. one cloth one membrane is a kind of composite geotextile material. Mainly used in water conservancy, transportation, tunnels, airports, metallurgical tailings, waste disposal sites, roofing seepage and other reinforced seepage control.

- Q: Does computer radiation-proof membrane really play a role?

- It is useful. but areas with maximum radiation of computers is at back of monitors, so if you want to prevent radiation, you'd better put some plants besides the computer, which can absorb much radiation than that of radiation-proof membranes.

Send your message to us

Epi Geomembrane - Polymer and Asphaltum EVA Adhesive Waterproofing Membrane Liner for Dam and Swimming Pool

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords