Polished Aluminum Mirror Sheet - Best Quality Aluminum Sheets for Sale in Philadelphia

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Polished Aluminum Mirror Sheet Best Quality in China

Aluminum Coil/Sheet | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

2. Application of Polished Aluminum Mirror Sheet Best Quality in China

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Polished Aluminum Mirror Sheet Best Quality in China

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

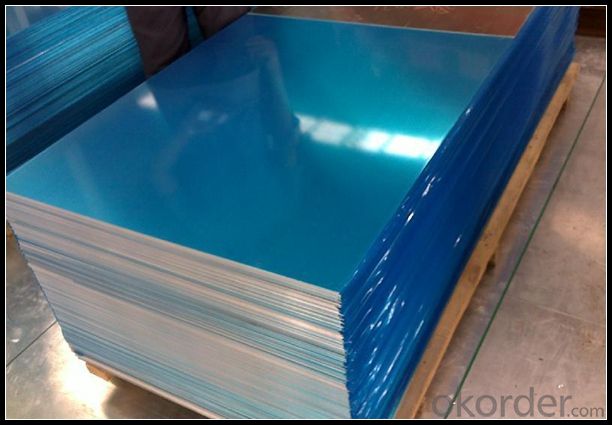

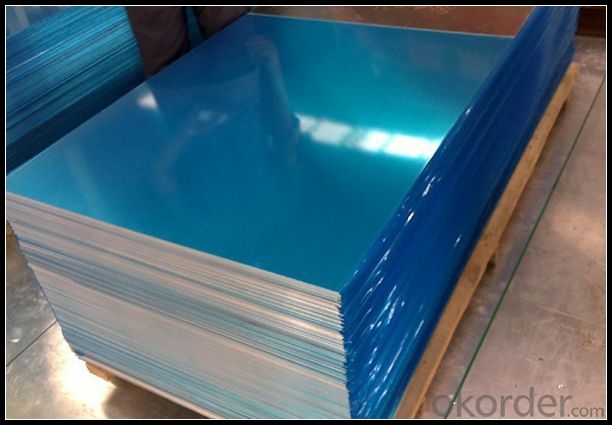

5. Image of Polished Aluminum Mirror Sheet Best Quality in China

6. Package and shipping of Polished Aluminum Mirror Sheet Best Quality in China

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Can aluminum sheets be used for packaging purposes?

- Yes, aluminum sheets can be used for packaging purposes. They are commonly used in the packaging industry due to their lightweight, corrosion-resistant, and malleable properties. Aluminum sheets can be easily formed into various shapes and sizes, making them ideal for packaging products such as food, beverages, pharmaceuticals, and cosmetics. Additionally, aluminum provides a protective barrier against moisture, oxygen, and light, ensuring the quality and longevity of the packaged goods.

- Q: Are aluminum sheets suitable for aircraft manufacturing?

- Yes, aluminum sheets are suitable for aircraft manufacturing. Aluminum is widely used in the aerospace industry due to its unique combination of properties such as lightweight, high strength, corrosion resistance, and excellent formability. These characteristics make aluminum an ideal material for constructing various aircraft components, including fuselages, wings, and structural parts. Additionally, aluminum alloys can be easily joined, allowing for efficient manufacturing processes. Overall, aluminum sheets play a crucial role in aircraft manufacturing, contributing to the overall performance, durability, and safety of the aircraft.

- Q: What is the bending radius of aluminum sheets?

- The bending radius of aluminum sheets depends on various factors such as the thickness of the sheet, the alloy of aluminum being used, and the type of bending process. Generally, aluminum sheets with a thickness of 1mm or less can be bent to a radius equal to the sheet thickness without cracking. For thicker aluminum sheets, the bending radius should be larger than the sheet thickness to avoid cracking or fracturing. As a general rule, the bending radius for aluminum sheets with a thickness between 1mm and 6mm should be at least 1.5 times the sheet thickness. For example, a 3mm thick aluminum sheet should have a minimum bending radius of 4.5mm. It is important to note that these guidelines are approximate and may vary depending on the specific alloy and temper of aluminum being used. Furthermore, different bending processes such as air bending, bottoming, or coining may require different bending radii. It is recommended to consult the manufacturer's specifications or seek professional advice for precise bending radius requirements for specific aluminum sheet applications.

- Q: What is the usage of aluminum sulfate for every ton of paper produce for kraft paper and news print

- Aluminium sulphate was the most extensively used chemical raw material in the papermaking industry. Its primary use was in the rosin sizing of paper where the rosin soap was reacted with aluminium sulphate to impart hydrophobis characteristics to the paper. The alum had a side benefit in fixing all types of anionic substances into the paper web. All types of paper, even those that were not sized, such as newsprint,were made using alum. This resulted in the paper being made under acidic conditions. The technology has changed markedly over the last 10 to 20 years with synthetic sizing agents being developed which do not require reaction with alum. In my country there is not 1kg of fine writing and printing paper made with rosin/ alum sizing, and no alum is used at all. Various synthetic highly charged cationic resins have been developed, such as polyacrylamide resins, polyethyleneimine resins, etc, whic are used as fixing and retention agents, so that alum has been virtually eliminated. To sum up the importance of aluminium sulphate as a papermaking chemical is now very limited.

- Q: Status of aluminum sheet F

- Status of aluminium plateThe F is free, and the aluminum sheet state is not limited. It is suitable for the products which have no special requirement for the working hardening and the heat treatment conditions in the forming process. The mechanical properties of the products in this state are not specifiedO is an annealed state, that is, a fully soft state, suitable for fully annealed products with minimum strength

- Q: How are aluminum sheets manufactured?

- Rolling is the process by which aluminum sheets are made. It begins with aluminum ingots that are heated and then passed through rolling mills. These mills, made of steel, have rotating rollers that squeeze and stretch the aluminum as it passes between them. This continuous rolling process refines the grain structure of the aluminum and improves its mechanical properties. To ensure the desired thickness and surface finish, the aluminum sheets may go through multiple passes in the rolling mills. Each pass gradually reduces the sheet's thickness until the desired thickness is reached. The final pass also gives the sheet its desired surface finish. After rolling, the aluminum sheets may undergo additional treatments like annealing or surface treatments. Annealing involves heating the sheets to a specific temperature and slowly cooling them to improve their strength and relieve internal stresses. Once manufactured and treated, the aluminum sheets are typically cut into desired sizes and shapes. This can be done through shearing with sharp blades or using specialized cutting machines. In summary, the manufacturing of aluminum sheets is a precise and intricate process that involves heating, rolling, treating, and cutting the aluminum to achieve the desired thickness, finish, and properties.

- Q: Are aluminum sheets suitable for insulation purposes?

- Indeed, aluminum sheets prove to be well-suited for insulation endeavors. Aluminum, being a notably reflective substance, possesses the ability to effectively impede the transmission of heat, rendering it a superb selection for insulation purposes. With its low emissivity value, aluminum reflects heat radiation rather than absorbing it, thereby aiding in the preservation of a uniform temperature within a given area and diminishing the necessity for heating or cooling. Moreover, aluminum sheets are characterized by their lightweight nature, straightforward installation process, and resistance to moisture, making them an eminently practical choice for insulation in a plethora of applications, including attics, walls, floors, and HVAC systems.

- Q: If you're familiar with some of my previous questions, you'll know I have a thing for DC-3's, and I'd like to buy one and fix it up at some point in my life. I was looking at pictures on Google for my desktop background and saw several with shiny chrome/aluminum bodies. Well, first of all, is it chrome or polished aluminum? Second, would I be able to buy a DC-3 painted this God-awful forest green and put whatever it is (chrome/aluminum) on said plane? Or is it something that the plane has to be built with originally?

- Polished aluminum... airplanes are not chrome plated... weight and the difficulty of electro-plating an entire aircraft are the reasons Could likely get some dissimilar metal corrsosion problems as well... Polished aluminum airplanes are absolutely beautiful, but it takes an incredible amount of work to get it that way, and a nearly equal amount of work to keep it up... plan on spending lots of time, money or both...

- Q: Can aluminum sheets be used for heat exchangers?

- Indeed, heat exchangers can utilize aluminum sheets. Aluminum, known for its remarkable heat conductivity, proves to be a perfect choice when it comes to heat exchangers. Its superior thermal conductivity facilitates exceptional heat transfer between fluids, leading to efficient heat exchange. Moreover, aluminum sheets possess the advantages of being lightweight, resistant to corrosion, and exhibiting commendable mechanical properties. These additional attributes further enhance their suitability for various heat exchanger applications.

- Q: This question asks about the various types of aluminum foil used specifically for the purpose of food packaging.

- <p>Aluminum foil used for food packaging comes in several types, each with specific applications: 1. Heavy-duty foil: Strong and durable, used for roasting meats and baking. 2. Light-duty foil: Thinner and more flexible, ideal for lining baking sheets and wrapping foods. 3. Reynolds Wrap: A brand known for its non-stick and heavy-duty aluminum foils, suitable for a wide range of cooking and baking needs. 4. Aluminum foil rolls: Available in various widths, used for general food wrapping and sealing. 5. Pre-cut aluminum foil squares: Convenient for individual food portions and small wrapping tasks. Each type offers different levels of heat resistance, malleability, and non-stick properties, catering to diverse food packaging requirements.</p>

Send your message to us

Polished Aluminum Mirror Sheet - Best Quality Aluminum Sheets for Sale in Philadelphia

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords