Heavy Aluminum Baking Sheets - Aluminum Mirror Sheet with Better Price in Our Warehouse

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 13 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Product Description

hot rolled and cold drawn and cold rolled aluminum sheet is widely used in the field of construction field and decoration field, etc.

There are many different grades, such as: 1000 series,6000 series,7000series, 8000 series, etc. The detailed grade are as follows: 1010,1100, 2024, 3003, 3105, 5052,5754,6061,6063,8011, etc.

The temper is include H14, H22, H24, H44,O, H112, H114,etc.

2. Main features of the product

a.Competitive price

c. Shortest service.

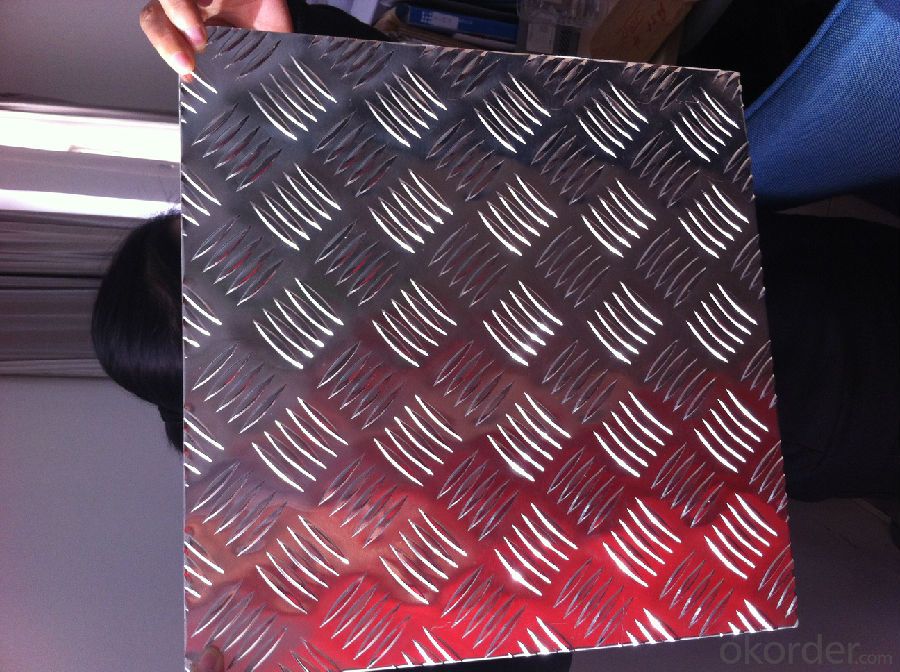

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm,1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 20mm to 2500mm, etc.

What is the length range:

---It is from 800mm to 6000mm, etc.

What is the MOQ for your products yet?

---Normally it is around 4 tons/each size.

How many tons did yoport in one year?

---Normally it is around 6000 tons totally.

Where is your client from?

---Normally it is from products?

---Normally they are aluminum sheet,big-5-bar aluminium checkered sheet,small-5-bar aluminium checkere sheetcasting coil, etc.

- Q: Are aluminum sheets suitable for marine vessel construction?

- Yes, aluminum sheets are suitable for marine vessel construction. Aluminum is lightweight, strong, and resistant to corrosion, making it an ideal material for building boats and ships. It also offers good thermal conductivity and is easily weldable, making it a popular choice in the marine industry.

- Q: Are aluminum sheets suitable for cladding?

- Yes, aluminum sheets are suitable for cladding due to their durability, lightweight nature, and corrosion resistance. Additionally, aluminum offers versatility in terms of design options and ease of installation, making it a popular choice for cladding applications in various industries.

- Q: How would you write the formula for aluminum sulfate and calcium chloride?

- Aluminium sulfate: Molecular formula Al2(SO4)3·16H2O Calcium chloride: Molecular formula CaCl2

- Q: Are aluminum sheets suitable for electrical conductors?

- Yes, aluminum sheets are suitable for electrical conductors due to their high electrical conductivity, lightweight nature, and cost-effectiveness.

- Q: Can aluminum sheets be easily formed or bent?

- Aluminum sheets possess the ability to be effortlessly formed or bent. The metal known as aluminum is remarkably pliable, signifying that it can be shaped into countless configurations without succumbing to fractures or breakages. This characteristic renders aluminum sheets exceedingly sought-after in sectors like automotive, aerospace, and construction, where the demand for intricate shapes and designs is paramount. Aluminum's pliability facilitates effortless manipulation via methods such as rolling, pressing, or bending, thereby empowering the fabrication of elaborate and tailor-made items. Furthermore, owing to aluminum's lightweight nature and remarkable strength-to-weight ratio, it stands as an ideal material for applications necessitating forming or bending, as it can be molded without adding excessive heft to the ultimate product.

- Q: This question asks for a list of various types of coatings that can be applied to aluminum sheets.

- <p>Aluminum sheet coatings are applied to enhance properties such as corrosion resistance, appearance, and durability. Common types include: 1. Anodized coatings, which provide a hard, wear-resistant surface. 2. Painted coatings, which can be solvent-based or water-based and offer a range of colors. 3. Powder coatings, which are electrostatically applied and then cured for a durable finish. 4. Laminate coatings, which are plastic films bonded to the aluminum for added protection and aesthetics. 5. Clear coatings, which are transparent and protect the aluminum without altering its appearance. 6. PVD (Physical Vapor Deposition) coatings, which provide a thin, hard layer for enhanced scratch and corrosion resistance. Each type serves different purposes and has unique properties that make it suitable for specific applications.</p>

- Q: Can the aluminum sheets be used for manufacturing musical instruments?

- Yes, aluminum sheets can be used for manufacturing musical instruments. Aluminum is a lightweight and versatile material that can be shaped and tuned to produce various musical sounds.

- Q: How are the aluminum plates cut?

- Cutting machine or plasma cutting machine, laser cutting, or electric saw. Generally thin aluminum (below 0.5mm) can be cut with a blade.

- Q: Is it feasible to recycle aluminum sheets and what factors contribute to its recyclability?

- <p>Yes, aluminum sheets can be recycled easily. Aluminum is one of the most recycled materials due to its lightweight, durability, and the energy efficiency of the recycling process. The recycling of aluminum requires only 5% of the energy needed to produce new aluminum from raw materials. Additionally, aluminum can be recycled indefinitely without losing its properties, making it an environmentally friendly choice. Proper sorting and collection systems are crucial for efficient recycling, and the demand for recycled aluminum is high in various industries, further facilitating its recycling process.</p>

- Q: Are the aluminum sheets suitable for manufacturing power distribution panels?

- Yes, aluminum sheets are suitable for manufacturing power distribution panels. Aluminum is a lightweight and durable material with excellent electrical conductivity, making it ideal for use in power distribution systems. Additionally, it is highly resistant to corrosion, which is crucial for ensuring the longevity and reliability of the panels.

Send your message to us

Heavy Aluminum Baking Sheets - Aluminum Mirror Sheet with Better Price in Our Warehouse

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 13 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords