Full Size Aluminum Baking Sheets - Aluminium Hot Sheet with Best Price in Warehouse

- Loading Port:

- Qingdao

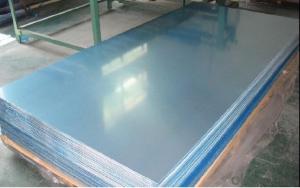

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t

- Supply Capability:

- 2000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Product Description

aluminum sheet is widely used in the field of construction field and decoration field, etc.

There are many different grades, such as: 1000 series, 2000 series, 3000 series, 5000 series, 7000 series, 8000 series,etc. The detailed grade are as follows: 1010, 1050,1060,1100, 2024, 3003, 3005, 3105, etc.

The temper is include H14, H22, H24, H112, H114,etc.

2. Main features of the product

a.Competitive price

c. Shortest service.

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm, 1500*3000mm, 1500*6000mm,etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 6000mm, etc.

What is the MOQ for your products yet?

---Normally it is around 5 tons/each size.

How many tons did you export in one year

Japan,SRI LANKA, BANGLADESH,Singapore,Fiji,Indonesia,Canada, Vietnam,Turkey,etc.

What is your mainly products?

---Normally they are aluminum sheet,small-5-bar aluminium checkered sheet, big-5-bar checkered aluminium plate, mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: I have to wire solar DC photovoltaic panels and have always used at least an 8 gauge wire. Recently, I installed a solar electric fence and they recommended special electric fence wire that can handle 10,000 volts. It looks aluminum. The fence techs told me copper is only rated for 600 volts. And the power will leak through the insulation. They also say copper will corrode and created insulated spots. Does this mean that aluminum doesn't corrode and is it superior to copper? Is is all a lobbying scam to force us to buy copper? Can I use the electric fence wire in my solar wiring?

- I believe the fence techs are mistaken. On an electric fence, the wire is basically bare, and the periodic 10 kV shocks are very low current. Aluminum is cheap, and once it develops surface oxidation, will last. Copper would last, too - it would just cost more. For photovoltaic panels, copper is almost always the wire of choice. At #8 or larger, use stranded, of course. Copper has less resistance, which will be important in low-voltage PV. Also, aluminum wire cannot be simply put into fittings designed for copper; it must use special fittings designed for aluminum, or connected to copper with a wire nut and antioxidant.

- Q: I get to do an aluminum blank for a fence and I am curious whether I can put slots in it with the router?I am not sure how thick it is, may say 3/16's.

- Yes you can use a router on aluminium. Use some kind of a fence, a piece of angle iron or a block of hardwood. Use a new bit, an old dull one will cause you problems. Pre-drill smaller holes than the slot width at each end of the slot. Stay back away from the end of the slot about 1/32 of an inch. Make several passes, at a depth of about 1/16 of an inch, per pass. If you can, make the slot with a bit smaller than the finished slot width. Use a 3/16 bit for a 1/4 inch slot. Use a 5/16 bit for a 3/8 inch slot. This will give cleaner slot edges and allow you to accurately make the slot width that you want. You can do this dry, but a little WD-40 oil will give even cleaner slot edges. Also climb mill the last pass on each slot edge to give a better/ smother edge. Climb Milling is pushing the router backwards of the way you normally travel in wood. Ben

- Q: The real bumper/ reinforcement bar that is behind the plastic bumpers. Magnet don't stick to it and it don't rust which both types of metal are pretty much like that.

- i agree, the main bumper support under the plastic bumper skin, is aluminum.

- Q: What are the standard tolerances for aluminum sheets?

- The standard tolerances for aluminum sheets can vary depending on the specific application and industry requirements. However, common tolerances for thickness range from +/- 0.005 to +/- 0.015 inches, while dimensions may have tolerances in the range of +/- 0.030 to +/- 0.125 inches. It is important to consult the appropriate industry standards or specifications for precise tolerances based on the specific needs of the project.

- Q: How to polish aluminum sheet to be bright?

- you must do some protection work, or you will fail once aluminum contacts air. Aluminum sheet is easy to be oxided and volatilized.

- Q: Can aluminum sheets be used for interior design purposes?

- Certainly, aluminum sheets are a great option for interior design purposes. The versatility of aluminum as a material offers numerous advantages when it comes to interior design applications. Its lightweight nature, durability, and resistance to corrosion make it an excellent choice for various design elements like wall coverings, ceiling panels, backsplashes, and room dividers. Aluminum sheets can be easily tailored and shaped into different forms, sizes, and finishes, providing limitless design possibilities. Moreover, aluminum is an environmentally-friendly material as it can be highly recycled. Its sleek and contemporary appearance adds a modern touch to any interior design project. In summary, aluminum sheets have gained popularity among interior designers due to their practicality, visual appeal, and sustainable nature.

- Q: What is the bending radius of aluminum sheets?

- The bending radius of aluminum sheets is influenced by several factors, including the sheet thickness, the type of aluminum alloy used, and the bending method employed. In general, aluminum sheets with a thickness of 1mm or less can be bent without cracking if the radius is equal to the thickness of the sheet. For thicker aluminum sheets, it is necessary to have a bending radius that exceeds the thickness of the sheet in order to prevent cracking or fracturing. As a rule of thumb, aluminum sheets with a thickness ranging from 1mm to 6mm should have a bending radius at least 1.5 times the sheet thickness. For instance, a 3mm thick aluminum sheet should have a minimum bending radius of 4.5mm. It is important to note that these guidelines are approximate and can vary depending on the specific aluminum alloy and temper utilized. Additionally, different bending processes, such as air bending, bottoming, or coining, may require different bending radii. To obtain precise bending radius requirements for specific applications of aluminum sheets, it is advisable to consult the manufacturer's specifications or seek professional advice.

- Q: Can aluminum sheet be used for food contact applications?

- Yes, aluminum sheet can be used for food contact applications. Aluminum is a safe and commonly used material for food packaging and cooking utensils due to its non-toxic properties, resistance to corrosion, and ability to maintain food quality and freshness.

- Q: Are 101 aluminum sheets suitable for medical equipment?

- No, 101 aluminum sheets are not suitable for medical equipment. Medical equipment requires materials that are highly durable, corrosion-resistant, and have excellent biocompatibility. While 101 aluminum is a strong and versatile alloy, it does not possess the necessary characteristics for medical equipment. Instead, medical equipment manufacturers typically use specialized alloys such as stainless steel or titanium, which offer superior strength, resistance to corrosion, and compatibility with the human body. It is essential to prioritize the safety and effectiveness of medical equipment by selecting appropriate materials that meet the specific requirements of the healthcare industry.

- Q: (given the fact that specific gravity of aluminum is 2.7)1. What is its volume?2. The ingot is suspended from a rope and totally immersed in water. What is the tension in the rope (the apparent weight of the ingot in water)?

- first find the volume of your aluminium. youll need this when analyzing the bouant force F(b). the sg of aluminum is 2.7 and the density of water is 1000 kg/m^3 so the density of aluminum is 2.7x1000=2700kg/m^3. the mass is 71N/g = 7.237512742 kg. so volume of our piece of aluminum = mass/density = 0.0026805603 m^3 now analyze the forces being applied to the system. There are three, the force of gravity F(g), the buoyant force F(b) and the tension T. Tension and buoyant force push up, gravity pulls down. the system will be at rest since the rope is holding it at rest. so T + F(b) - F(g) = 0 T + (Volume aluminum X density water X g) - (MAss of aluminum x g) = 0 T + (0.0026805603x1000x9.81) - (71 N (given in problem)) = 0 Solving for T, T = 44.70370346 N = 45 N using sig figs.

Send your message to us

Full Size Aluminum Baking Sheets - Aluminium Hot Sheet with Best Price in Warehouse

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t

- Supply Capability:

- 2000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords