Plastic Tubes PPR Fitting Elbow Equal Diameter Food Hygiene Non-Toxic

- Loading Port:

- Tianjin

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 11700 pc

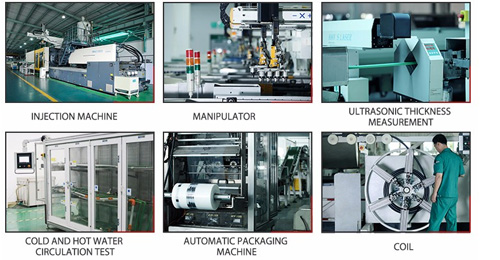

- Supply Capability:

- 710000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Features

1. Corrosion resistance

PPR pipes and fittings can resistant to most chemical corrosion; it can withstand PH value range 1-14 high concentration of acid and alkali corrosion over a wide temperature range.

2. Installation performance

PPR pipe PPR pipe is light in weight, and the operation installation is easy, which make it available to weld again. It is very important that pipe and pipe fittings can be welded together in seconds with a simple tool. Compared to traditional connection methods it can save 40%~50% of the time.

3. Safety Indicators

The basic component of PPR is carbon and hydrogen which is simple. It keeps in line with food hygiene regulations, non-toxic. If you use PPR pipe, there will no dirt in the inner wall or “secondary water pollution” caused by rust any more.PPR pipe ,green building materials, is more suitable for transporting drinking water.

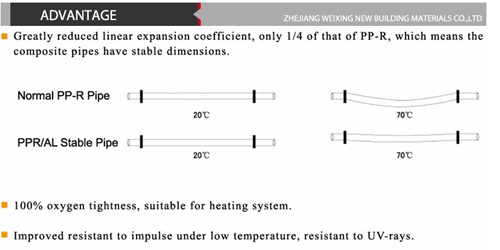

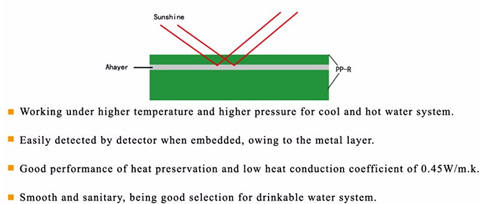

Advantages of PPR pipe

1. Maximum operating temperature can up to 95℃; it can work in a long term under the condition of 70℃ and 1.0Mpa.

2. PPR pipe density is only 1/8 of metal pipe; pressure resistance strength test is up 5Mpa, with good toughness, impact resistance.

3. Inner diameter of PPR pipe is little bigger than that of pipe fittings, which can ensure not to increase the resistance to fluid flow.

4. Inner wall of PPR pipe is smooth, no rust, no scaling, small fluid resistance

5. PPR pipe has excellent insulation properties, can significantly reduce the vibration and noise caused by the flow of liquid.

6. PPR pipe energy consumption is only 20% of steel pipe; its thermal coefficient is also only 1/200 of steel pipe, reducing heat loss greatly.

7. PPR pipe is poor electrical conductor material, which can avoid galvanic corrosion phenomena.

8. With poor thermal conductivity, PPR pipe can reduce condensation.

9. PPR pipes, fittings are recyclable.

Application

1. Hot and cold drinking water supply system of civil and industrial buildings

2. Clean, pure water piping system

3. Beverage production and transport systems

4. Industrial liquid delivery system

5. Central air conditioning system

6. Hot water circulation Heating System

7. Compressed air piping system

8. Garden and greenhouse irrigation systems

FAQ

PPR pipe and fittings selection principles

PPR pipe and fittings selection principles:

1. Note that the overall pipeline utilization factor C (ie a safety factor) to determine:

General case, and make long-term continuous temperature <70 ℃, optional C = 1.25; on important occasions and long-term continuous use temperature ≥70 ℃, and possibly a long time to run at higher temperatures, the optional C = 1.5;

2. For cold water (≤40 ℃) system, the choice of P.N1.0 ~ 1.6MPa pipe, tube; used for hot water systems use ≥PN2.0MPa PPR pipes and fittings.

3. After considering the above three principles, SDR pipe fittings should not exceed SDR pipe, pipe wall thickness that is not less than the same size of pipe wall thickness.

Points to note:

PPR pipes are widely used in industrial and residential buildings life, health and drinking water supply and hot water heating .There are two kinds of PPR pipes for hot and cold water. The cold water pipe wall is thin, hot pipe wall thickness, so that the hot water in terms of fracture resistance good performance of many pipe, hot water pipe prices are also more expensive than cold water pipe some of many manufacturers to be safe, hot and cold water, regardless of the construction process, cracking, improve the safety factor PPR pipe fittings which are applied to note the following Some applications often encountered in some cases, should pay attention.

1. PPR pipe fittings alone corrosion resistant can be applied to transport long items such as chemistry and strong adaptability to the environment. In order to ensure a good application of the pipe, installed outdoors or in direct sunlight must be wrapped dark protective layer.

2. Molding technique PPR pipes using, is the quality and credibility of security, leak, and note must be taken to prevent pipe expansion and deformation of technical measures in surface mounted or buried Concealed piping time.

3. PPR installation process should prevent paint and other organic pollutants and pipes and fittings in contact.

4. PPR pipe fittings hot melt connection safe, odorless, in which the connection process should be noted, PP-R pipe in addition to some special pipes and fittings using other connection methods, such as metal pipes or water connection using the threaded inserts flange or other mechanical connections, the rest should be using hot melt connection, the integration of the pipe, no leakage points.

5. Special pipe with metal pipe installation connected to metal insert, not too much force, so as not to damage threaded fittings, resulting in junction leakage.

6. Heating pipes and fittings shall prevent over-heating, so thinner. Pipes deform in the pipe fittings.

7. When the hot-melt intubation and correction, rotation is strictly prohibited.

8. The operation should not have live fire, open flame is prohibited bake bend the pipe.

9. The PPR installation that is interrupted or completed at exposure must be temporarily closed well to avoid debris from entering.

- Q: What's the diameter of the white plastic tube in the kitchen, about 10cm? What should I do if the water leaks?

- Glue bonding: to the building materials shop to buy a small bottle of PVC pipe special glue (other glue is not good), and then find a small piece of suitable PVC pipe fragments, will dew point paste firmly.

- Q: This connector is used with plastic tubing and is inserted into a rubber stopper (which is in turn inserted into a waste flask). The 'wings' are for holding the tubing in place. Previously this connector is believed to have been bought through Fisher Scientific, but recent searches (with out knowing the name of this item) have not yielded results. If anyone has any suggestions of where to obtain this or what this is called it would be greatly appreciated.

- Can't see the image. Is it a condenser?

- Q: I'm thinking about making a homemade UV clarifier for my pond

- It probably would go through the clear stuff. I have a Vortec that houses the UV bulb in a glass tube that the water flows past and it works very well. I don't know if I'd try the homemade route, but if you're handy enough, more power to you.

- Q: Are plastic tubes resistant to impact or breakage?

- Yes, plastic tubes are generally resistant to impact and breakage. They are designed to withstand various levels of force and are less likely to crack or break compared to other materials. However, the level of resistance may vary depending on the type and quality of plastic used.

- Q: One end has a handle, the other has a fitting with small plastic ball in it,it is coupled at center with threaded piece.What is it

- On this description alone, I think it's a valve for a hose. It goes to a connection inside the house and sticks outside the house for the hose. These are built this way so that in winter, the actual mechanism of the ball valve can't freeze.

- Q: Are plastic tubes suitable for vacuum applications?

- Plastic tubes are generally not suitable for vacuum applications as they are prone to collapsing under the pressure differential created by the vacuum.

- Q: Looking for just the top lid, but everyplace only offers the lid, plastic cup and straws.

- off the counter at Mcdonalds

- Q: What are the different materials used to make plastic tubes?

- There are various materials used to make plastic tubes, including polyvinyl chloride (PVC), polyethylene (PE), polypropylene (PP), and polystyrene (PS).

- Q: looks like its for air bubbles, etcwhat do i need to do with it, hook it up with, etc?thanks all

- You need an air pump and a bit of silicone air line tubing.

- Q: Difference between u-PVC drain pipe and pressure hard polyvinyl chloride water supply pipe (UPVC)

- From the material, there is no difference. UPVC drainage and pressure feed water UPVC are only different in wall thickness. Because of the high rainfall considered a full pipe flow, so the pipe at the bottom needs pressure.There is no pressure test in the standard, so it is generally not pressure, and the water supply pipe must be under pressure.But you have used UPVC water supply pipe instead of rainwater drainage, and there is no pipe fitting in the water supply system of the pipe fittings.Or with HRS high-rise stormwater dedicated tubes, but also PVC materials, and pipe fittings are also pressure. The price is cheaper than the pipe.

Send your message to us

Plastic Tubes PPR Fitting Elbow Equal Diameter Food Hygiene Non-Toxic

- Loading Port:

- Tianjin

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 11700 pc

- Supply Capability:

- 710000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords