Petroleum Oil Pump with API 610 Standard

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

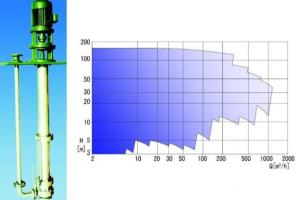

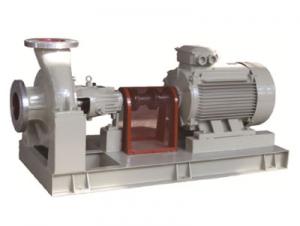

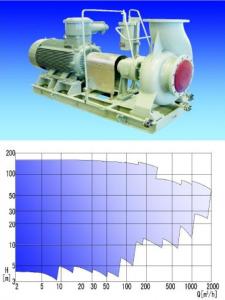

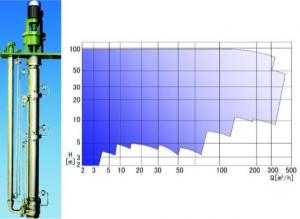

KDY petroleum oil pump with API 610 standard is developed with internationally advanced technologies. It is designed for long-distance transportation of liquids without solids and corrosion, especially of crude petroleum, petrol-oils and other high pressure applications.

1. Quality guaranteed. It has API610 (8th Edition) standard design and certified by ISO9001.

2. Easy operating. With both suction inlet and discharge outlet located in pump casing, it has no need to disturb the piping and motor when maintaining and serving the internal parts, even no need to open the pump cover when replacing mechanical seals and bearings.

3. Safe. Twin volute design and opposed symmetric impeller arrangement combined to obtain perfect radial and axial balances under all operation conditions. Double suction impellers plus inducers may also be utilized for reduction of cavitations.

4. Flexible. Pump shaft, with computer optimized design, keyed with the impellers symmetrically arranged on the shaft, rotor assembly strictly checked with computer program to ensure controlled radial flexibility and dynamic balance,.

5. Advanced leak-proof technology. Advanced hydraulic model engenders compact construction with spacious internal passageway efficient for crude oil of high viscosity. The high-strength bolts, computer optimized designed, connect upper and lower casings together and ensure a leak-less operation at super pressure conditions.

6. Heat resisting. Shaft sealed with high pressure mechanical seals that are forcibly cooled and rinsed with solution treated through vortex separations, which makes it applicable for pumping of high temperature liquids and crude oil, besides the mechanical seals are located at the low pressure area far away from the center where the high pressure zone lies.

7. Bearing and coupling systems are designed for heavy duty and high speed operation. The SKF centripetal thrust bearing plus self-lubricating or forcibly lubricated slide bearing shall balance the remnant axial force. Air and water cooling are available for slide bearings, elastic bolts coupling and membranes plus intermediate coupling selectable.

8. Pump temperature, vibration and leakage are monitored and alarmed both locally and remotely. Automatically control of the pump could be realized through connection with customer’s auto systems.

- Q: 110 engine oil pump gear is always broken, what should I do?

- The crankcase needs a lot of cleaning. It's too dirty. It's stuck in the oil pump

- Q: How do I check if the oil pump is working properly?

- Oil pump directly linked engine, engine transfer pump is also transferred, the work is normal to see the pressure, the pressure is insufficient, the oil lamp will light, will alarm.

- Q: How to change the oil pump 1.8 MAGOTAN

- Replacement is more complicated, it is recommended to replace the car repair shop.

- Q: How does the oil pump affect the car?

- Senior technician Xiao Zhang answers for you. If you don't understand, welcome to ask.

- Q: How to change the oil pump?

- You have to find a professional chef to install

- Q: What's the reason that I changed the new oil pump instead of the engine oil?

- When you switch the pump oil pump to oil or oil is that gambling is dead

- Q: The oil pump is coming up. Why is the oil lamp still on?

- Check the oil pressure sensor

- Q: What about the balance shaft of the automobile engine oil pump? How much does it cost to fix?

- Working hours one thousand, accessories count. If the balance shaft can be replaced, no heavy repair will be required.

- Q: How to change the diesel engine oil pump?

- First of all, you need to release all the oil, disassemble the engine oil pan, remove the oil pump assembly and replace it.The oil pump is the main component in the lubrication system of diesel engine. Its function is to press the engine oil to a certain pressure and force it to the moving surface of the engine parts. The structure of oil pump can be divided into two types: gear type and rotor type. Gear type oil pump is divided into internal gear type and external gear wheel type, generally referred to as gear pump.

- Q: How to check the motor oil pump oil supply is normal?

- In the premise of the normal amount of oil, usually need to check whether the oil pressure is normal (usually around 0.3MPa), if the oil pressure is low, usually the oil circuit, overflow valve failure or oil pump failure. After cleaning and adjusting the oil relief valve, the pressure is still low. The fault must be the oil pump failure.The effect of the oil pump is to press the engine oil to a certain pressure and force it to the surface of each part of the engine. If the oil pump is damaged or leaking, it is necessary to disassemble the oil pan, take out the oil pump and replace it, and clean or replace the oil pump inlet strainer at the same time.

Send your message to us

Petroleum Oil Pump with API 610 Standard

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords