Aluminum Expanded Metal Sheets - PE PVDF Color Coated Aluminum for Building Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m²

- Supply Capability:

- 9000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium Reflective sheet

Alloy or No.: Alloy

Alloy No.: AA1050, AA1060, AA1070, AA1070

Thickness: 0.2-3mm

Width: 10mm-2200mm

Length:10mm-2200mm

Tensile strength: ≥140N/mm2

Elongation: ≥2%(H26)

Yield Strength: ≥120N/mm2

Usage: Lights, grille lamp, tunnel lamp, solar collector etc.

1. Applications:

Furniture:Wardrobe, office equipment, cooking appliance

The transport industry:Automobile components, bicycle parts, body of railway coaches

Other:water tanks, enamel, barrels, tubes, chimney, grain barn, stamping, cable wrapper

2. Advantages:

Light-weight, high-strength, elegant and long-life, quake-proof, easy-installation, heat-insulated, colorful, anti-rust, water-proof, sound-insulated, etc

3. Our Company:

CNBM was established in November, 2005. We provide the annual output of 600,000 tons of zinc/alum-zinc, 600,000 tons of cold rolled sheets and 200,000 tons of color coated steel. Our main markets are Southeast Asia, the Middle East, Ireland, Italy, and Africa and South /NorthAmerica, Chile and other regions.

Our company focuses on hot-dipped galvanized steel coils, galvalume steel coil/sheet, PPGI/ PPGLsteel coil, corrugated/color-coating corrugated sheets.

Please provide the following information when placing an order:

1. Product name

2. Product standard

3. Material Grade

4. Specification

5. Zinc Coating

6. Surface treatment

7. Weight

8. Package requirements

if you show interestings on my products, you could contact with us.

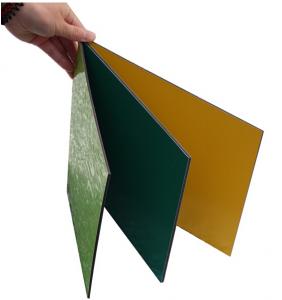

- Q: Are aluminum sheets available in different colors?

- Yes, aluminum sheets are available in different colors. They can be coated or painted in various shades to suit different aesthetic preferences and design requirements. The color options range from traditional metallic finishes like silver and gold to a wide array of vibrant and contemporary colors. The availability of different colors allows aluminum sheets to be used in diverse applications such as architectural cladding, signage, automotive industry, and home décor. Additionally, the color coating or paint on aluminum sheets also provides additional protection against corrosion and enhances their durability.

- Q: What are the advantages of using aluminum sheets compared to other materials?

- There are several advantages of using aluminum sheets compared to other materials. First, aluminum is lightweight, making it easier to handle and transport. Second, aluminum has corrosion resistance properties, ensuring durability and longevity. Third, aluminum sheets can be easily formed and molded into various shapes, allowing for versatility in applications. Additionally, aluminum is a good conductor of heat and electricity, making it suitable for use in industries such as aerospace and electrical engineering. Lastly, aluminum is recyclable, making it an environmentally friendly choice.

- Q: What are the weight and density of aluminum sheets?

- The thickness and dimensions of aluminum sheets determine their weight and density. In general, aluminum has a density of approximately 2.7 g/cm³ or 2700 kg/m³. To calculate the weight, you can multiply the density by the volume of the sheet. For instance, if you have a 1-meter by 1-meter sheet that is 1 millimeter thick, the volume would be 0.001 cubic meters (1 meter x 1 meter x 0.001 meter). By multiplying this volume by the density of aluminum, you would find that the weight of the sheet is 2.7 kilograms (0.001 cubic meters x 2700 kg/m³). Keep in mind that these values may vary depending on the specific dimensions and thickness of the aluminum sheet.

- Q: Do 101 aluminum sheets have any specific certifications or standards?

- Yes, 101 aluminum sheets typically have certifications and standards that ensure their quality and performance. These may include certifications like ASTM (American Society for Testing and Materials) and standards such as AA (Aluminum Association) standards, which verify the material's composition, mechanical properties, and manufacturing processes. Additionally, specific industry certifications like ISO 9001 (International Organization for Standardization) may be applicable to ensure consistent quality control during production.

- Q: Can aluminum sheets be used for architectural cladding?

- Yes, aluminum sheets can be used for architectural cladding. Aluminum is a popular choice for cladding due to its durability, lightweight nature, and resistance to corrosion. It is commonly used in both residential and commercial buildings for its aesthetic appeal and versatility in various architectural designs.

- Q: What are the advantages of utilizing aluminum sheets in construction projects in terms of environmental impact?

- <p>Using aluminum sheets in construction offers several environmental benefits. They are highly recyclable, which reduces waste and conserves natural resources. Aluminum is lightweight, reducing the carbon footprint associated with transportation. It also has a high strength-to-weight ratio, leading to less material usage and lower energy consumption in production. Additionally, aluminum's reflective properties can help in reducing heat absorption, contributing to energy efficiency in buildings. Moreover, aluminum production technology has advanced to minimize harmful emissions, making it a more sustainable choice for construction materials.</p>

- Q: What are the different types of surface treatments available for aluminum sheets?

- Aluminum sheets can be treated in a variety of ways to achieve specific purposes and unique characteristics. Anodizing, painting, powder coating, and polishing are some of the most commonly used surface treatments for aluminum sheets. Anodizing involves the creation of a thick oxide layer on the surface of the aluminum sheet. This treatment not only enhances the appearance by providing a range of colors but also increases corrosion resistance and durability. Anodized aluminum sheets are widely utilized in architecture, automotive parts, and electronics. Painting is another popular surface treatment for aluminum sheets. It entails applying a layer of paint to enhance appearance and provide additional protection against corrosion and wear. Painted aluminum sheets are commonly seen in signage, building facades, and decorative applications. Powder coating is a type of surface treatment where a dry powder is applied to the aluminum sheet and then heated to create a protective layer. This treatment offers excellent durability, resistance to weathering, and a wide range of color options. Powder coated aluminum sheets find extensive use in the construction industry, as well as for automotive parts and appliances. Polishing involves buffing the aluminum sheet to create a smooth and reflective surface. This treatment enhances the aesthetics, making it perfect for decorative applications like furniture, jewelry, and architectural accents. In summary, the selection of surface treatment for aluminum sheets depends on desired appearance, functionality, and application requirements. Each treatment provides distinct advantages and characteristics, allowing for versatility and customization in various industries.

- Q: How do I join aluminum sheets together?

- To join aluminum sheets together, various methods can be utilized depending on the specific application and desired outcome. Here are several commonly employed techniques: 1. Riveting: Aluminum sheets can be joined by using rivets, which are small metal fasteners. This involves drilling holes in the sheets and then inserting the rivets, which are permanently secured by deforming or compressing them. Riveting is a widely used and durable method for joining aluminum sheets. 2. Welding: Aluminum welding can be accomplished through methods such as gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), or laser welding. These techniques involve melting the aluminum at the joint, allowing it to fuse and create a strong bond upon cooling. Welding necessitates specialized equipment and expertise, but it provides a robust and permanent joining solution. 3. Adhesive bonding: This method employs industrial-grade adhesives specifically designed for bonding aluminum. The adhesive is applied to the surfaces to be joined, and then the sheets are pressed together and allowed to cure. Adhesive bonding results in a clean and aesthetically pleasing joint, although it may not be suitable for high-stress applications. 4. Mechanical fasteners: Another option for joining aluminum sheets is the use of screws, bolts, or nuts. This method entails drilling holes in the sheets and employing fasteners to secure them together. Mechanical fasteners offer a strong and adjustable joint, making disassembly easier if required. Before selecting a joining method, it is important to consider factors such as the strength requirements, appearance, ease of assembly, and disassembly of the application. Additionally, adhering to safety guidelines and seeking professional advice is essential if uncertainty or lack of experience with joining aluminum sheets exists.

- Q: Are aluminum sheets suitable for food preparation surfaces?

- Yes, aluminum sheets are suitable for food preparation surfaces. Aluminum is a lightweight and durable material that is commonly used in the food industry. It is non-toxic, non-reactive, and does not release any harmful chemicals when it comes into contact with food. Aluminum sheets are also easy to clean and maintain, making them a popular choice for food preparation surfaces in both commercial kitchens and home kitchens. Additionally, aluminum has excellent heat conductivity, allowing for even cooking and baking. However, it is important to note that aluminum can react with acidic or salty foods, causing a metallic taste. To prevent this, it is recommended to use a layer of parchment paper or silicone baking mat as a barrier between the aluminum sheet and the food.

- Q: Can aluminum sheets be used for decorative wall panels?

- Yes, aluminum sheets can be used for decorative wall panels. Aluminum is a versatile material that can be easily manipulated to create various designs and finishes. It is lightweight, durable, and offers a sleek and modern look, making it a popular choice for decorative wall applications.

Send your message to us

Aluminum Expanded Metal Sheets - PE PVDF Color Coated Aluminum for Building Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m²

- Supply Capability:

- 9000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords