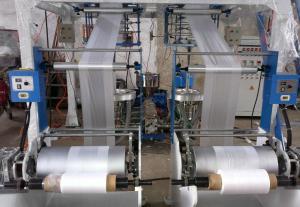

PE High Speed Blowing Film Machine CE ISO

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

SJ-50, 55.65 High-speed Film Blowing Machine

Use:

Its extruder, cylinder and screw rods are made of quality alloy steel that have been nitrized and processed in a precision way. Hence it is sound in hardness, durable in corrosion resistance. The specially-designed screw is of sound quality in plasticizing, which helps increase the production capacity. It is applied to blowing the plastic films like low density polytene (LDPE), high density polytene(HDPE) and linear low density polytene (LLDPE). It is widely applied to producing the packing bags for foodstuff, clothing, rubbish bag and vest ones.

OPTIONAL EQUIPMENT:

1) COROAN TREATER

2)ROTERY DIE DEVICE

3)THICKNESS AUTO CONTROLLER

4)FILM WIDTH AUTO CONTROLLER

Productions Pictures:

Use:

Its extruder, cylinder and screw rods are made of quality alloy steel that have been nitrized and processed in a precision way. Hence it is sound in hardness, durable in corrosion resistance. The specially-designed screw is of sound quality in plasticizing, which helps increase the production capacity. It is applied to blowing the plastic films like low density polytene (LDPE), high density polytene(HDPE) and linear low density polytene (LLDPE). It is widely applied to producing the packing bags for foodstuff, clothing, rubbish bag and vest ones.

OPTIONAL EQUIPMENT:

1) COROAN TREATER

2)ROTERY DIE DEVICE

3)THICKNESS AUTO CONTROLLER

4)FILM WIDTH AUTO CONTROLLER

Productions Pictures:

| Model | SJ-50 | SJ-55 | SJ-65 |

| Diameter of Screw | φ50 | φ55 | φ55 |

| Max. Width of Folded Film | 100-600 | 200-800 | 300-1000 |

| Single-face Thickness of Film(mm) | 0.01-0.10 | 0.01-0.10 | 0.01-0.10 |

| Max. Extrusion(kg/h) | 55 | 75 | 100 |

| L/D | 30:1 | 30:1 | 30:1 |

| Die head size | Φ60, φ100 | Φ80, φ150 | Φ120, φ200 |

| Power of Main Motor(kw) | 15 | 22 | 37 |

| Power of Traction Motor(kw) | 1.5 | 1.5 | 1.5 |

| Max.line speed(m/min) | 100 | 100 | 100 |

| Overall Dimension (L x W x H) | 6000×1600×4000 | 6500×2200×4700 | 7000×2300×5250 |

| Weight(T) | 2.0T | 2.5T | 3.5T |

- Q: What's the problem of air compressor?

- The following reasons: 1. head bearing damage, 2 air compressor bearing broken, 3. rotor 4. cylinder, or loose belt. What is the specific reason to find a professional repair master, open inspection to determine?. If no problems are identified after the inspection, or no mechanical failure occurs, the following methods can be used to improve the noise!

- Q: What is the optimum oil temperature of vacuum oil filter?

- 1. open the valve on the intake pipe of the vacuum pump 29, start the vacuum pump 31, and pay attention to the rising of the vacuum.2. the relief valve will be opened, the pressure adjustment at 0.3Mpa (factory has been adjusted).

- Q: What's the difference between an oil filter and an oil press?

- The oil in the wok heating material first, let the material molecular re combination again into the press in the press, by squeezing out oil, commonly known as the "oil", the crude oil containing substances affect human health, to his oil filter filter, after filtering the oil can be eaten.

- Q: Transformer oil filter how to choose?

- Our company is also transformer oil inlet, according to our oil situation, the choice is a two stage transformer oil vacuum oil filter, after use, there is a great improvement

- Q: Hydraulic press to buy automatic integration of good or alone to buy the right?

- The oil press of an integral oil press is connected with an oil filter, and a vacuum oil filter is usually used. And the vacuum oil filter is relatively small, because the large oil filter can not hang.

- Q: I bought the yigayi press... To peanut oil processing. Others froth overflow, can precipitate it. Oil, foam heat. But it was cold, processed oil directly frozen. They call headquarters, they let me use salt and alkali and alum. In accordance with the proportion of with boiling water stir, add the oil mix, I give people processing oil. So how could I home on the edge of this ah, what a good way?

- I used the steam pan and the frame oil filter, and the oil didn't foam at all!

- Q: What happens when the oil heater is fired and the heater is tripped?

- Oil filter is mainly used to improve the cleanliness of machinery and electrical oil, so as to give full play to the best performance and extend the service life of equipment.

- Q: How to select oil filter in small hydropower station?

- The two are mechanical methods of purification. Now the city's pressure filtration can completely eliminate mechanical impurities, but in addition to water is not complete; vacuum filtration can completely remove moisture, but it can not eliminate mechanical impurities.

- Q: Working principle and operation instructions of vacuum oil filter for oil press

- The vacuum oil filter is designed according to the different boiling points of water and oil. It consists of a vacuum heating tank, a fine filter, a condenser, a primary filter, a water tank, a vacuum pump, an oil drain pump and an electric cabinet

- Q: What is the difference or connection between the oil filter and the oil filter?

- Second, the oil filter is usually fixed to a part of the system, and the oil filter is usually a mobile filter unit, without the need for fixed installation,

Send your message to us

PE High Speed Blowing Film Machine CE ISO

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches