Paddle Laminating Roller-vacuum infusion process

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

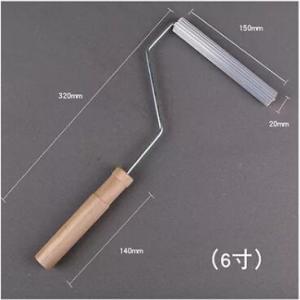

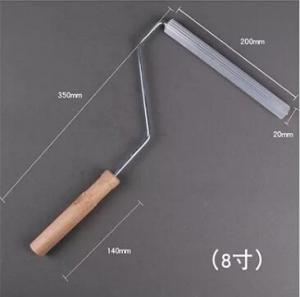

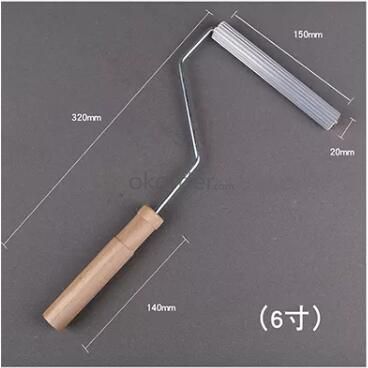

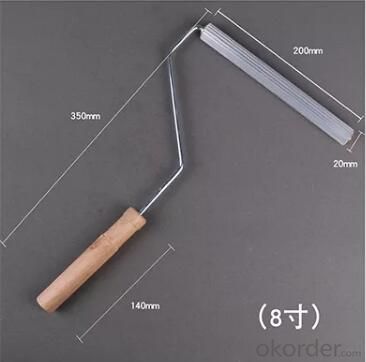

Paddle Laminating Roller

Product Description

Paddle Laminating Roller is widely used in the production of glass fiber reinforced plastic, and the inner surface of the bubble roller puncture, for removing air bubbles from lamination, leveling and compaction of resin coating to drive bubbles.

Technique Data

Type: | Roller Brush |

Handle: | Wooden and plastic |

Brush Material: | Aluminum |

Feature | Non-slip handle, multi-size, good material, high quality, durable |

Use | Remove air bubbles |

Color | Customized |

Size | 2‘’3‘’4‘’5‘’6‘’8‘’ |

MOQ | 100pcs |

Delivery Detail | About 15-20 days after having received the deposits. |

- Q: What is the typical diameter of fiberglass chopped strand?

- The typical diameter of fiberglass chopped strand is around 10 to 25 micrometers.

- Q: What are the safety precautions to be taken while handling fiberglass chopped strand?

- When handling fiberglass chopped strand, it is important to take several safety precautions. First, wearing appropriate personal protective equipment such as gloves, safety goggles, and a respirator is essential to prevent direct contact with the fibers and to avoid inhalation of any dust or particles. Additionally, it is recommended to work in a well-ventilated area to minimize the concentration of airborne fibers. When cutting or handling the material, sharp tools should be used carefully to prevent injuries. Lastly, it is crucial to follow proper disposal procedures for any waste or scraps to minimize environmental impact.

- Q: How does the electrical conductivity of fiberglass chopped strand affect its performance?

- The electrical conductivity of fiberglass chopped strand plays a crucial role in determining its overall performance. Fiberglass is known for its excellent insulating properties, which make it highly resistant to electrical current. However, when fiberglass chopped strand is mixed with other materials, such as resins, polymers, or metals, it can significantly alter its electrical conductivity and subsequently affect its performance in various applications. In applications where electrical conductivity is desired, such as in the production of electronic components or conductive composites, the addition of conductive additives to fiberglass chopped strand can enhance its electrical conductivity. This modification allows for the efficient transfer of electrical current throughout the material, making it suitable for applications that require the conduction of electricity. On the other hand, in applications where electrical insulation is necessary, the inherent electrical insulating properties of fiberglass chopped strand are highly advantageous. The low electrical conductivity of fiberglass ensures that it acts as an effective barrier against the flow of electrical current. This property makes fiberglass chopped strand ideal for use in insulation materials, electrical enclosures, or any application where electrical safety is paramount. Moreover, the electrical conductivity of fiberglass chopped strand can also impact its performance in terms of mechanical strength and durability. In some cases, the addition of conductive materials can affect the bonding and adhesion of the chopped strand to other materials, potentially compromising its overall strength and structural integrity. Conversely, the high electrical insulation properties of fiberglass can contribute to its mechanical strength by preventing the degradation of the material due to electrical factors like corrosion or electrical discharge. In summary, the electrical conductivity of fiberglass chopped strand greatly influences its performance in various applications. Whether it requires high electrical conductivity for efficient conduction or low electrical conductivity for effective insulation, understanding and manipulating the electrical properties of fiberglass chopped strand is essential in optimizing its performance in specific applications.

- Q: Does fiberglass chopped strand improve the impact resistance of composite materials?

- Composite materials can benefit from the use of fiberglass chopped strand, as it effectively enhances their impact resistance. By incorporating small, randomly oriented fibers into the manufacturing process, the chopped strand reinforces the composite material. In the event of an impact, the fiberglass chopped strand plays a crucial role in distributing and absorbing the force, thereby preventing concentrated damage. Acting as a protective barrier, the fibers disperse the impact energy throughout the composite material, reducing the likelihood of cracks or fractures. Moreover, fiberglass chopped strand also improves the interfacial bonding between the fibers and the composite's matrix, resulting in better load transfer capabilities. This enhanced bonding strength significantly contributes to the overall impact resistance of the composite material. To summarize, the inclusion of fiberglass chopped strand in composite materials greatly enhances their impact resistance by effectively dispersing and absorbing impact energy, preventing localized damage, and improving the overall strength and durability of the composite.

- Q: What are the typical post-processing treatments for fiberglass chopped strand composites?

- The post-processing treatments for fiberglass chopped strand composites can differ depending on their specific application and desired final product properties. However, there are some common treatments that can be employed: 1. Achieving the desired shape and dimensions involves trimming and cutting the excess fiberglass material after the initial molding or lay-up process. This step refines the aesthetics and functionality of the final product. 2. To enhance the cosmetic appearance and durability of fiberglass chopped strand composites, surface finishing techniques like sanding, grinding, or buffing can be utilized. These techniques eliminate imperfections, smooth rough edges, and create a polished or matte finish. 3. Customization and protection can be achieved by applying various coatings or paints to the composites. Coatings such as gel coats, epoxy, or polyurethane increase resistance to UV radiation, moisture, and chemicals. Painting can also be done for aesthetic reasons or to match specific design requirements. 4. In specific applications, fiberglass chopped strand composites may need to be bonded or joined with other materials or components. Techniques like adhesive bonding, mechanical fastening, or welding can be used to establish a strong and reliable connection between different parts of the composite structure. 5. Heat treatment can be employed to enhance the mechanical properties of fiberglass chopped strand composites, depending on the specific resin used in the manufacturing process. This process involves subjecting the composite to controlled heating and cooling cycles, which increase strength, stiffness, and dimensional stability. 6. Thorough quality control and inspection are crucial after the post-processing treatments to ensure that the fiberglass chopped strand composites meet the required specifications and standards. This involves visual inspection, dimensional checks, non-destructive testing, and mechanical testing to verify the integrity and performance of the final product. It is important to consider that the post-processing treatments may differ based on the manufacturing process, resin system, intended application, and customer requirements. Therefore, consulting with experts or referring to technical specifications is essential to determine the most suitable post-processing treatments for fiberglass chopped strand composites in a specific context.

- Q: Can fiberglass chopped strand be used in electrical insulation varnishes?

- Indeed, electrical insulation varnishes can make use of fiberglass chopped strand. This versatile material boasts remarkable electrical insulation characteristics. Its incorporation into varnishes amplifies the insulation and thermal resistance of the coating. By adopting the chopped strand form, fiberglass seamlessly integrates into the varnish composition, furnishing reinforcement and enhancing the mechanical strength of the insulation. Furthermore, fiberglass chopped strand aids in diminishing shrinkage and cracking of the varnish throughout the curing procedure, thereby advancing the insulation's overall performance and durability.

- Q: How is fiberglass chopped strand made?

- Fiberglass chopped strand is made through a manufacturing process that involves several steps. Firstly, glass fibers are melted at high temperatures in a furnace. These fibers are made from a combination of raw materials such as silica sand, limestone, soda ash, and other additives. Once melted, the molten glass is then extruded through tiny holes in a device known as a bushing. This process is called fiberization, and it results in the formation of numerous fine glass filaments. These filaments are then rapidly cooled with a blast of air or water, causing them to solidify into solid fibers. Next, the solid fibers are gathered into bundles known as strands. These strands are then chopped into shorter lengths using mechanical cutters, hence the term "chopped strand." The chopped strands are typically around 3-6mm in length, although this can vary depending on the desired application. After being chopped, the strands are collected and processed further. They may undergo additional treatments such as applying a sizing agent or a binder to enhance their performance and compatibility with specific resin systems. These treatments also help to improve the adhesion between the fiberglass and other materials it will be combined with, such as resins or polymers. Finally, the chopped strands are packaged and made available for use in various industries. They can be incorporated into a wide range of products, including composites, insulation materials, automotive parts, and construction materials, among others. In summary, fiberglass chopped strand is made by melting glass fibers, extruding them into thin filaments, cooling and solidifying the filaments, chopping them into shorter lengths, and then applying additional treatments as needed. This process results in a versatile material that offers excellent strength, durability, and flexibility for a variety of applications.

- Q: How does the fiber orientation distribution of fiberglass chopped strand affect the properties of composites?

- The properties of composites are greatly influenced by the distribution of fiber orientation in fiberglass chopped strand. This distribution refers to how the fibers are aligned and arranged within the composite material. Firstly, the mechanical properties of the composite are affected by the fiber orientation distribution. Typically, fiberglass chopped strands are randomly oriented within the matrix, creating a three-dimensional network. This random distribution results in isotropic properties, meaning the composite exhibits similar mechanical behavior in all directions. However, if the fibers are aligned in a specific direction, such as unidirectional alignment, the composite becomes anisotropic, meaning it has different mechanical properties in different directions. For example, composites with aligned fibers have improved stiffness and strength along the fiber direction, but reduced properties in other directions. Secondly, the thermal properties of composites are influenced by the fiber orientation distribution. When the fibers are randomly distributed, heat is transferred in multiple directions, leading to isotropic thermal conductivity. Conversely, if the fibers are aligned, heat transfer is more efficient along the fiber axis, resulting in anisotropic thermal conductivity. This anisotropic behavior is advantageous when designing composites for specific applications that require controlled heat dissipation or insulation properties. Thirdly, the fiber orientation distribution affects the electrical properties of composites. Randomly distributed fibers create a conductive network throughout the material, enabling good electrical conductivity in all directions. However, if the fibers are aligned, the electrical conductivity becomes anisotropic, with higher conductivity along the fiber direction. This anisotropic behavior can be advantageous in applications where electrical conductivity needs to be controlled, such as in electronic devices or electromagnetic shielding. Furthermore, the fiber orientation distribution impacts the overall durability and fatigue resistance of composites. Randomly distributed fibers help distribute stress and strain more evenly throughout the material, enhancing its resistance to crack propagation and fatigue failure. In contrast, composites with aligned fibers may experience stress concentrations along the fiber direction, making them more vulnerable to failure under cyclic loading. In conclusion, the fiber orientation distribution of fiberglass chopped strand has a significant impact on the properties of composites. It determines the mechanical, thermal, electrical, and durability characteristics of the material, allowing for tailored composite designs to meet specific application requirements.

- Q: How does the moisture content of fiberglass chopped strand affect its performance?

- The moisture content of fiberglass chopped strand can significantly affect its performance. Fiberglass is a composite material made of fine glass fibers embedded in a matrix of resin. These fibers provide the strength and rigidity to the material. However, when moisture is present, it can weaken the bond between the fibers and the resin, leading to a decrease in overall performance. Moisture in fiberglass chopped strand can cause several issues. Firstly, it can lead to a reduction in mechanical properties such as tensile strength, stiffness, and impact resistance. This is because moisture weakens the bonding between the fibers and the resin, reducing the load-carrying capacity of the material. Secondly, moisture can lead to dimensional changes in the fiberglass. When the material absorbs moisture, it can expand or swell. This can cause warping, distortion, and changes in shape or size. In applications where tight tolerances are required, such as in the automotive or aerospace industries, this can be a significant problem. Furthermore, moisture can also contribute to the growth of mold, mildew, or fungi on the fiberglass surface. This not only affects the appearance of the material but can also deteriorate its structural integrity over time. To mitigate the negative effects of moisture, it is crucial to properly store and handle fiberglass chopped strand. It is recommended to store the material in a dry and controlled environment. Additionally, the use of moisture-resistant coatings or treatments can help protect the fiberglass from moisture absorption. In conclusion, the moisture content of fiberglass chopped strand has a direct impact on its performance. It can weaken the structural integrity, reduce mechanical properties, cause dimensional changes, and promote the growth of mold or fungi. Therefore, it is essential to ensure that the material remains dry and properly protected to maintain its optimal performance.

Send your message to us

Paddle Laminating Roller-vacuum infusion process

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords