Peel Ply-vacuum infusion process fiberglass

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Peel Ply

Product Description

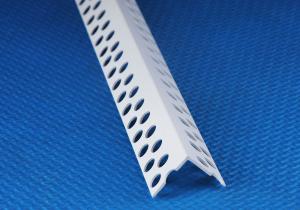

Peel Ply is a plain weave nylon fabric with red or blue stripe. Under scoured and heat set process, the surface is very clean and the fabric is very strong which gives perfect release property, widely used in vacuum infusion process, Aerospace, Wind power, Marine, fiberglass or carbon fiber vacuum infusion etc.

Technique Data

Material: | PA66 nylon fiber |

Area Weight: | 85 g/m2 can be customized to 105g |

Width: | 2500px (max 4500px) |

Temperature resistant | 230℃ |

Pattern: | plain weave |

Thickness: | 0.16 mm |

Color: | white+red stripe line |

Density: | 17 X 17 counts/cm |

- Q: How can the aluminum alloy window be fixed with the corner and the whole frame?

- The general approach is to fix the whole frame in the frame mounted on the wall and hit the iron, steel nails or expansion screws, then iron and fixed, then fill foam, after solidification with cement lime and smooth wall.

- Q: How to solve the corner problem in the kitchen basket?

- The design of the basket at the corner solves the awkward position problem of the cupboard, and the reasonable partition is suitable for placing small objects of various sizes, and the extraction design is also convenient. If your home is not a font cabinet, it will certainly change direction in the cabinet when there is a corner space. Various corner pull baskets are the best solution for cabinet corner cabinets. When the cabinet of these two doors open, people do not sigh the way to accept the ultimate. Although the contents of the collection of many and miscellaneous, but each layer of a layer to show in front of, at a glance.

- Q: What do you mean by corner steering of Bao Chun 730ABS steering wheel?

- In addition, through the photoelectric encoder to collect corners, but in automotive applications, due to the reliability of photoelectric sensors and other issues, the use of less products, not much described here.

- Q: What skills do you have in turning corners and corners of integrated wiring?

- Construction method without curved bend angle joint. A curved corner joint is used when the line slot needs to be bent at 90 degrees.

- Q: Automatic CNC band saw machine, product use and advantages?

- Trolley type CNC feeding band sawing machine with rotary angle of 0 degrees to 45 degrees: real and the workpiece rotation, can be completed from 0 degrees to 45 degrees between the bevel of arbitrary angle.

- Q: Indoor beauty glue, how can you hit the corner, playing perfect?

- General use of aloe vera gel, as long as regular manufacturers are available. Including perfect products.

- Q: Steering wheel angle sensor operating principle

- The steering wheel angle sensor, SAS, steering, wheel, sensor, serves as an integral part of the vehicle ESP/ESC (vehicle stability control system), which is installed in the steering column below the steering wheel. It is generally connected to the PCM via the CAN bus. Generally can be divided into analog steering wheel angle sensor and digital steering wheel angle sensor.

- Q: What are the applicable industries of corner labeling machines?

- Applicable products: all kinds of cartons, such as poker boxes, mobile phone packaging boxes, etc.. And widely used in printing, food, daily chemicals, electronics, medicine and other industries.

- Q: Ask about the product performance and advantages of DJ series corner band sawing machines!

- The super rotary saw adopts the Longmen type structure. It has good rigidity and stability, and the cutting interface is smooth.

- Q: Pcliao injection of smooth surface not light is going on

- Defects visible on the surface of injection molded products include dark spots, gloss differences, or areas of spray, as well as surface wrinkling or orange peel. Typically, these defects occur near the gate or behind the sharp corner away from the gate region. From the two aspects of mold and molding process, we can find out the causes of these defects.

Send your message to us

Peel Ply-vacuum infusion process fiberglass

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches