New FRP Composite Filament Pipe Winding Machine with Different Styles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 20 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

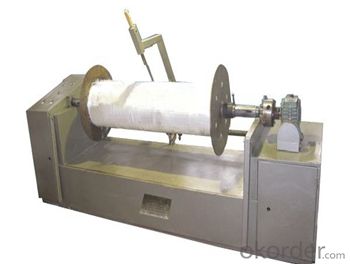

New FRP Composite Filament Pipe Winding Machine with Different Styles

Product Description:

It is mainly applied to the production of FRP pipe, FRP pipe with sand, FRP tank and so on.

Product Features:

1.All the machine parts adopt international standard steel make machine with high stability.

2. System failure can be automatically alarmed and show fault point. Make maintenance easily.

3. Particular parts adopt special purpose wire, durable in use.

4. Size and layout of machine can be made according to customer requirements.

Product Parameter:

Name | New FRP Composite Filament Pipe Winding Machine with High Frequency |

Brand | CMAX |

Weight | 8-13T |

Dimension(L*W*H) | 13mx3.5mx2.2m |

Power | 35KW |

Voltage | 380V |

Product Type | FRP Machinery |

Certification | ISO9001:2008 |

Application | Pipe |

Raw material | Fiber Reinforced Plastic |

Place of Origin | Beijing, China (Mainland) |

Color | Customizable |

Warranty | 12 Months |

Time of Delivery | 30-45 days |

Product Pictures:

Our Services:

1.Researches and development team by knowing the importance of the FRP usage in industry and

construction , have successfully conducting different researches and studies projects. At the present , it has several government- supported projects available .

2.Design and engineering services has been given idea from customers, and make out the things you

imaged. Especially developing on new machinery.

3.Istallation and construction team is experienced with installation, commissioning and training service at customer’s factory. In this way, the customer is able to handle management of equipment

themselves soon.

4.Maintenance service is applied when customer can’t solve problem themselves. Mainly at equipment,

software, tools…etc.

5.Technical support is the most importance in production. As long as FRP developing, new and

advanced process, material, equipment appeared. We are giving the eyes on the world FRP relative

news and supply customer advanced service.

FAQ:

Q: Why we are your best choice?

A:We have direct factory and many years of export experience, and offer the best price with high

quality product, timely delivery, also have good after-sales service, therefore with good reputation on boards and with many clients have good long-term business relationship.

Q: Can I order the product with special size?

A: Of course you can, also we will produce the products according to your detail requests.

- Q: It's a small plastic shell for the processing plug! How much is the small injection molding machine 100Which great God knows what equipment a small plastic shell needs?! It's a small plastic shell for the processing plug! How much is the small injection machine?! Where does Wuxi sell injection molding machine?!

- I'm a little far from your territory. I'm in Guangdong and I have a lot here. You go to Alibaba network to find a lot of, this device in China has been very popular.

- Q: I do not know the classification details and processing procedures, as well as the purchase of such equipment, the need for experienced master guidance, you can also join the cooperation,

- Different kinds of waste plastics have different characteristics. As far as impurity content is concerned, waste materials in the middle and outer corners of the factory produce impuritiesThe content of less than 0.1%, piled up scrap for a period of time and other products used for% impurity content 0.1 ~0.5%, mixed with aluminum, cloth and paper composite plastic waste impurities are often more than 10%. For used waste plastics,According to different use conditions, will include ultraviolet radiation, heat, oxygen aging effect, pollutants.Ring. For different shapes of waste plastics, the volume density of materials after crushing is very different, film, sheet, flatThe volume density of the crushing material is smaller, which is a problem that must be considered in the process of waste plastics recycling and granulation.Two. Pretreatment of waste plasticsFrom discarded packages, such as bags, shopping bags, bottles, cans, boxes and waste agricultural film waste plastics, inPretreatment prior to granulation. The pretreatment process mainly includes classification, cleaning, crushing and drying.Classification work is the classification of miscellaneous waste plastics products according to the type of raw materials and product shapes classification. By raw materialsClass sorting requires operators to have a good knowledge of identifying plastic varieties, and the purpose of sorting is to avoid different speciesThe resulting polymers are incompatible with recycled materials and have poor performance. They are classified according to the shape of the product to facilitate the use of waste plasticsThe crushing process can be carried out smoothly, because the film, flat and fabric used in crushing equipment with some thick and hard wareThe crushing equipment often can not replace each other.

- Q: What kind of equipment do we need? How much is the approximate cost? Seek your heroes guidance and guidance!

- Equipment include: film blowing machine, bag machine, punching machine, printing machine, etc., to invest one hundred thousand up and down, but also need a few tons of raw materials as a turnover, and then start production, I do not know very well, just listen to someone else said...

- Q: Want to buy an injection molding machine to do some plastic products, equipment about how much money ah? What needs to be prepared?

- The machine depends on whether you buy new or second-hand. Second hand 120T is 780 thousand better. There are also 340 thousand... Plus the surrounding facilities. Crusher, mixer, cooling tower. Freezing water machine. These are tens of thousands of pumps.. Get ready. 200 thousand is enough.. But it depends on what you do.. If the material is expensive, you have to figure it out

- Q: where there are advanced environment-friendly recycled plastic processing equipment?

- Environmental protection recycling plant, this is a systematic project, the use of granulation machine is usually used granulator, need to be matched with waste water filtration, sedimentation, purification treatment pond, waste gas purification equipment.

- Q: How much is the investment? TenCan be processed daily plastic bags, woven bags, garbage bags, clothes bags, there are printed words like that.There is a 300 square foot factory empty home now, best can step can do this ~ ~ wherever he goes high profits? Just try to compare and see what is worth investing in! Trouble you expert pointing! Thanks.

- Investment of about fifty thousand, the production of barrels, pots and other daily necessities.

- Q: Hello, small plastic processing plants need what equipment, how much the price, how to process, the size of the site, thank you

- The project is very good. I want to do it very much. This machine goes there to buy it,

- Q: What kind of machine is needed for the production of plastic products?

- Seventy thousand or eighty thousand an injection molding machine, a crushing machine, a drying machine forty thousand or fifty thousand, workshop, rent, labor, water and electricity to ten thousand months Duoliangwanyi, mold materials, another operator, of course cost large scale is low.

- Q: Benefits of plastic products

- The most lightweight plastic, chemical stability, will not rust; the good impact resistance; the transparent and has good wear resistance; the good insulation, low thermal conductivity; the general molding, coloring is good, the processing cost is low; most heat-resistant plastic, thermal expansion. Easy burning; poor dimensional stability, easy deformation; majority of poor low temperature resistant plastic, low temperature brittle; easy to aging; some of the plastic soluble in solvents.

- Q: Is there any pollution in the processing of plastic raw materials?

- Yes, we have.The plastic itself contains chemicals, in the production process, will react with other substances, produce some odor and so on, so in the production environment must be ventilated, and will produce gas in the process of mechanical production, in production and after the residue, waste water and so on, these are the production of pollution.

Send your message to us

New FRP Composite Filament Pipe Winding Machine with Different Styles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 20 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords