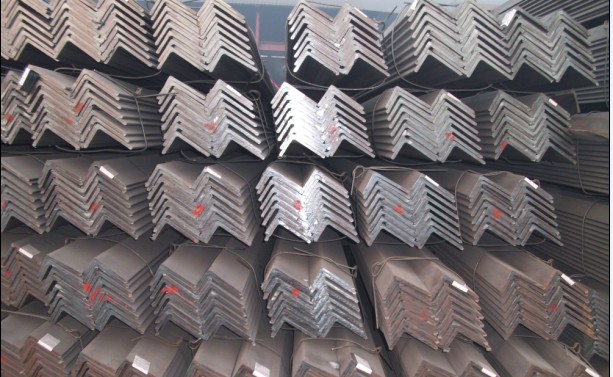

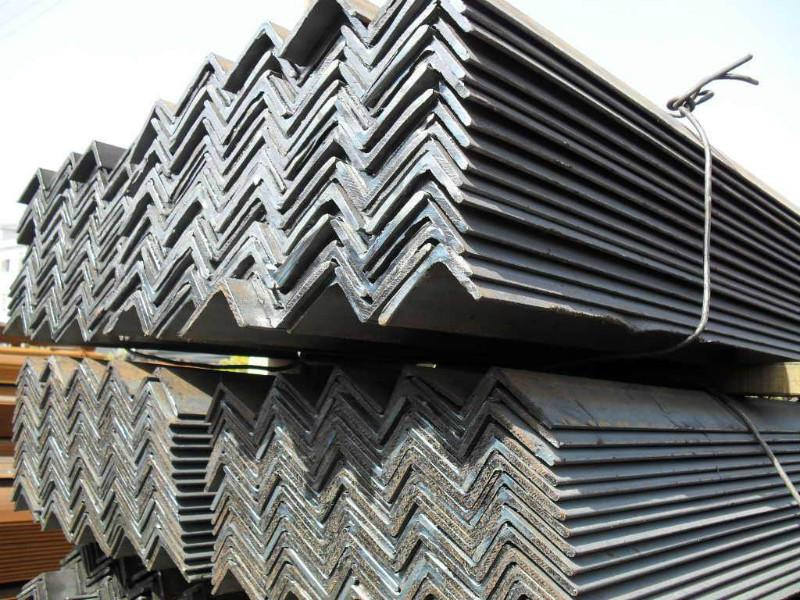

MS equal/unequal black & galvanized steel angle bar with high quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 35 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Hot rolled carbon steel angle bar

Prompt delivery,Premium quality

Accept customized sizes

Accept client's LOGO

Mild steel angle bars OR Low content alloy angle bars | |

| Size | 25mm*25mm-250mm*250mm |

Wall thickness | 1.5mm-25mm |

Length | 1m-12m ,by customer’s requiremnts |

Internatioanal Standard | ISO 9001-2008 |

Standards |

ASTMA53/ASTM A573/ASTM A283/Gr.D/

BS1387-1985/

GB/T3091-2001,GB/T13793-92, ISO630/E235B/

JIS G3101/JIS G3131/JIS G3106/

|

Materials |

Q195,Q215,Q235B,Q345B,

S235JR/S235/S355JR/S355

SS440/SM400A/SM400B |

Product Category | Metallurgy,Mineral &Energy |

Technique | HOT ROLLED |

Packing | 1.Big OD:in bulk 2.Small OD:packed by steel strips 3.woven cloth with 7 slats 4.according to the requirements of customers |

Usage | Mechanical&manufacture,Steel strcuture, Shipbuilding,Bridging,Automobile chassis |

Main market | Middle East,Africa, Asia and some Uropean country and America , Australia |

Country of origin

| China |

Productivity | 15000 Metric Tons pet Month |

Remark | Payment terms :T/T ,L/C Terms of trade :FOB ,CFR,CIF ,DDP,EXW Minimum order : 10 tons Lead time :on or before 3-15 working days . |

Company information

| We, ShunYun Industrial located in PuTuo district,ShangHai city China. Our products are sold to all over the country and exported to more than 50 countries such as the EU,theUnitedStates,Australia,Southest, Asia,the Middle East,etc. We shall a good -will of credit quality and prompt delivery and hold the belief of "quality for improvement ,credit for developments and customer first".So that can offer clients advanced products and satisfied service. We sincerely would like to set up business relationship with clients from all over the world in long term business. We view credibility as life. |

Logo | ShunYun shipping mark or your company logo |

Another Name | angle steel bar ,angle steel , steel angle , mild steel angle ,carbon steel bars |

Surface processing | you can Galvanized,coated,or as your request |

Technical | Shanghai Shunyun Industrial |

you Can | Customized Sizes |

Contact information

| TEL: +86-021-62153163 FAX: +86-021-62152536 |

- Q: Can steel angles be used for supports in bridges?

- Yes, steel angles can be used for supports in bridges. Steel angles provide structural stability and strength, making them suitable for supporting heavy loads in bridge construction.

- Q: What is the standard tolerance for steel angles?

- The standard tolerance for steel angles typically ranges from +/- 1/8 inch to +/- 1/4 inch, depending on the specific dimensions and requirements of the angle.

- Q: How do you determine the deflection of a steel angle?

- To determine the deflection of a steel angle, you need to consider various factors such as the material properties of the steel, the dimensions of the angle, and the applied load. The deflection of a steel angle can be determined using mathematical equations and formulas, specifically those related to structural mechanics. Firstly, you need to determine the moment of inertia (I) of the steel angle, which depends on its cross-sectional shape and dimensions. The moment of inertia represents the resistance of the angle to bending and is a crucial parameter in calculating deflection. The moment of inertia can be obtained from engineering handbooks or calculated using mathematical formulas specific to the shape of the angle. Next, you need to determine the load that is applied to the steel angle. This load can be in the form of a concentrated force, a distributed load, or a combination of both. The magnitude and distribution of the load will influence the deflection of the angle. Once you have determined the moment of inertia and the applied load, you can use the appropriate deflection equation or formula to calculate the deflection of the steel angle. The specific equation used will depend on the type of loading and the boundary conditions of the angle (e.g., whether it is simply supported or fixed at both ends). For example, if the steel angle is subjected to a concentrated load at its midpoint and is simply supported, you can use the equation for deflection of a simply supported beam under a concentrated load. This equation relates the deflection (δ) to the applied load (F), the length of the angle (L), the moment of inertia (I), and other relevant constants. It is important to note that the deflection calculated using these equations is an approximation and does not take into account factors such as material imperfections, fabrication tolerances, or the effects of dynamic loading. Therefore, it is always advisable to consult relevant design codes, standards, or engineering handbooks to ensure accurate and safe design practices when determining the deflection of a steel angle.

- Q: How do you determine the axial capacity of a steel angle?

- The axial capacity of a steel angle can be determined by calculating the maximum compressive load it can withstand before it fails. This calculation involves considering factors such as the material strength, cross-sectional properties, and geometric dimensions of the angle. The capacity is typically determined using established engineering formulas and design standards specific to steel angles.

- Q: Are steel angles available in different alloys?

- Different alloys are available for steel angles, providing a wide range of options. Typically, steel angles are made from carbon steel, which is a versatile and common type of steel. However, specific applications may call for other alloys. For instance, stainless steel angles are made from an alloy containing chromium, offering increased resistance to corrosion. In addition, high-strength low-alloy (HSLA) steel angles combine carbon steel with small amounts of elements like manganese, phosphorus, or sulfur to enhance strength and durability. This variety of alloys allows for a diverse range of applications and properties to meet specific needs across various industries.

- Q: Are steel angles susceptible to fatigue failure?

- Yes, steel angles can be susceptible to fatigue failure. Fatigue failure occurs when a material undergoes repeated loading and unloading cycles, leading to the initiation and propagation of cracks within the material. Steel angles, like any other structural components, can be subject to cyclic loading conditions, such as vibrations, oscillations, or repeated stress applications. Fatigue failure in steel angles is influenced by various factors, including the material's properties, the geometric shape of the angle, the magnitude and frequency of the applied loads, and the presence of any defects or stress concentrations. The presence of notches, welds, or sharp corners can act as stress raisers, leading to localized stress concentrations and potential crack initiation sites. To mitigate the risk of fatigue failure, engineers and designers consider several strategies. Firstly, understanding the anticipated loading conditions and designing the structure with appropriate safety factors can help ensure that the steel angles are not subjected to stress levels that exceed their fatigue strength. Secondly, minimizing stress concentrations through proper design, such as using rounded corners or fillets, can help distribute the stress more uniformly and reduce the likelihood of crack initiation. Additionally, regular inspection and maintenance of structures can help identify any potential fatigue cracks and allow for necessary repairs or replacements.

- Q: Is there a screw that can be made like angle iron, but not a right angle, just a single piece of material? That's the way to break the angle iron in two. What if it's called? Thank you, professionals!

- Drilling tail screw quality is poor, hardness is not good

- Q: What are the different methods of connecting steel angles together?

- When connecting steel angles together, there are various methods available depending on the specific application and structural needs. Some commonly used techniques include: 1. Welding: Utilizing a welding electrode, welding is an effective and frequently employed method. It involves melting the edges of the angles and joining them together, creating a permanent and robust connection. 2. Bolting: Another popular approach is bolting, which involves using bolts, nuts, and washers to secure the angles in place. This method allows for a strong connection that can also be easily disassembled if necessary. 3. Riveting: Riveting entails the use of metal pins known as rivets to connect steel angles. It requires drilling holes in the angles and inserting the rivets, which are then hammered or pressed to create a permanent connection. 4. Adhesive bonding: Adhesive bonding involves the use of industrial adhesives to connect steel angles. The adhesive is applied to the surfaces of the angles, which are then pressed together. This method provides a durable and corrosion-resistant connection. 5. Mechanical connectors: Mechanical connectors, such as steel clips or brackets, are also suitable for connecting steel angles. These connectors are designed to securely clamp the angles together, providing a rigid connection. When selecting the appropriate method, it is crucial to consider factors such as load-bearing requirements, structural design, and environmental conditions. Consulting with a structural engineer or a professional in the field is recommended to ensure the appropriate method is chosen for the specific application.

- Q: How do you design bracing using steel angles?

- Designing bracing using steel angles involves determining the required strength and stiffness of the bracing members, selecting appropriate steel angles based on their load-bearing capacities, and arranging them in a configuration that effectively resists the applied forces and moments. The design process typically includes analyzing the structure's loadings, determining the required bracing forces, calculating the required cross-sectional area of the steel angles, and verifying the design against relevant design codes and standards. Additionally, considerations such as connection details and fabrication constraints also play a role in designing bracing using steel angles.

- Q: Can steel angles be used for support beams in warehouse construction?

- Yes, steel angles can be used for support beams in warehouse construction. Steel angles are commonly used in construction for their strength and load-bearing capabilities. They provide structural support and stability, making them suitable for supporting heavy loads in warehouse buildings.

Send your message to us

MS equal/unequal black & galvanized steel angle bar with high quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 35 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords