Ac Aluminum Coil Oxidation Mirror Finish Aluminium Coil for Building Materials

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Mirror Finish Aluminium Coil for Building Materials

l Product Information

1. Alloy: 1100, 1145, 1050, 1060, 1070, 3003, 3105, 3A21, 3005, 3105, 3A21, 5052,5754,5082, 5083, 5182,5A03, 6063,6061,6082,8011 |

l Packaging & Delivery

Packaging detail: Standard seaworthy exporting carton, Wooden pallets, waterproof paper and plastic coverage or as customer's requirements

Delivery detail: about 25 days from received original L/C or advance payment.

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323.

Aluminium coil is a popular product in the market of CNBM. With advanced technology and equipment, CNBM has sold its hight quality aluminium coil to the world.

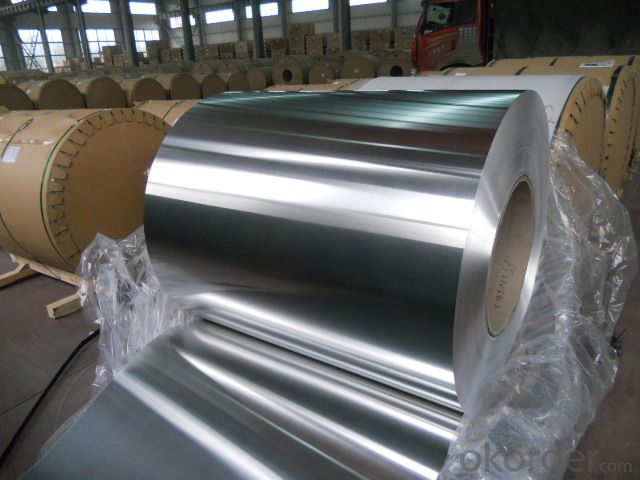

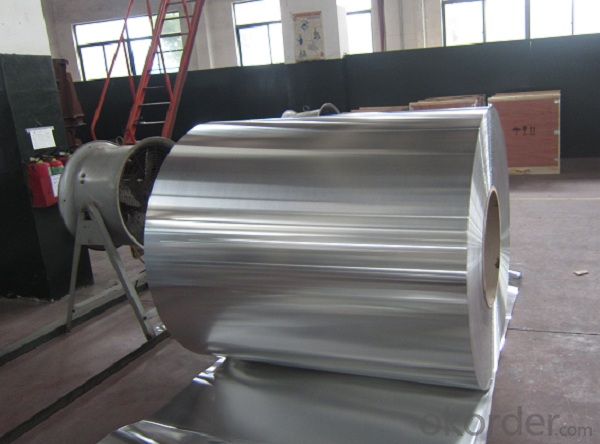

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

- Q: What are the typical standards and specifications for packaging aluminum coils?

- <p>The standard specification for aluminum coil packaging varies depending on the industry and region, but generally includes the following: The coil is typically wrapped in a protective film to prevent damage and corrosion. It is often strapped with steel or plastic bands to secure the coil during transportation. The packaging may also include wooden pallets or crates for stability. The dimensions and weight of the packaging are tailored to the coil's size and thickness. Compliance with international standards such as ASTM, ISO, or specific industry standards is crucial. It's important to note that exact specifications can differ based on customer requirements and the end-use application of the aluminum coil.</p>

- Q: Can aluminum coils be used in marine environments?

- Yes, aluminum coils can be used in marine environments. Aluminum is a popular choice for marine applications due to its excellent corrosion resistance. It forms a protective oxide layer on its surface when exposed to air, which helps prevent further corrosion. This oxide layer is particularly effective in marine environments where there is exposure to saltwater or high levels of humidity. Additionally, aluminum is lightweight, making it easier to handle and install in marine applications. It is also highly durable and can withstand harsh conditions, including exposure to UV rays and extreme temperatures. Therefore, aluminum coils are commonly used in various marine applications such as boat hulls, shipbuilding, offshore structures, and other marine equipment.

- Q: What are the advantages of using aluminum coils over other materials?

- There are numerous benefits to utilizing aluminum coils as opposed to alternative materials. To begin with, aluminum boasts a lightweight composition, thereby facilitating simpler handling and transportation. This characteristic also renders it more cost-effective, as it necessitates less energy for manufacturing and installation. Furthermore, aluminum exhibits a remarkable resistance to corrosion. It remains unaffected by rust, even when subjected to harsh environmental conditions, rendering it highly suitable for outdoor applications. The resulting durability ensures an extended lifespan and diminishes maintenance expenses in the long term. Moreover, aluminum coils excel in terms of heat transfer properties. Possessing a high thermal conductivity, they facilitate efficient heat exchange. This renders them ideal for crucial applications such as heating, ventilation, and air conditioning systems. In addition, aluminum serves as an eminently recyclable material. It can undergo multiple recycling processes without compromising its quality or performance. This not only curtails waste and contributes to environmental sustainability but also lowers production costs. Lastly, aluminum coils offer tremendous versatility in terms of design and customization. They can be effortlessly molded, shaped, and coated to meet specific requirements. This flexibility permits a wide array of applications across diverse industries, including automotive, construction, electronics, and aerospace. In conclusion, the array of advantages associated with aluminum coils, encompassing their lightweight nature, corrosion resistance, heat transfer properties, recyclability, and versatility, establishes them as the favored choice over alternative materials.

- Q: Are aluminum coils suitable for food storage containers?

- Aluminum coils are indeed appropriate for food storage containers. This material is highly favored for such containers because of its many beneficial qualities. To begin with, aluminum is lightweight, which makes it easy to handle and transport. Moreover, it possesses excellent thermal conductivity, allowing for quick heating or cooling, making it perfect for storing both hot and cold food. Additionally, aluminum is resistant to corrosion and does not react with acidic or alkaline foods, ensuring that the taste and quality of the food remain unaffected. Furthermore, aluminum is an environmentally friendly choice as it is sustainable and can be recycled. However, it is worth noting that aluminum containers should be coated with a food-grade lining to prevent any potential interaction between the metal and the food, particularly with acidic foods. In conclusion, aluminum coils are a suitable option for food storage containers due to their lightweight nature, thermal conductivity, resistance to corrosion, and recyclability.

- Q: I bought some cheap aluminum foil, but one weighs much less than the other brand for the same thickness and length, why?What is the other made of? Is it still good to use for grounding something?Thank you.

- Aluminum foil is aluminum foil, it has nothing but aluminum in it. One of them is misstating the thickness, or you are mistaken about the weight or width.

- Q: How much cube is the 0.9mm aluminum rolling?

- This is a common problem. Anyone who had received high school education can calculate it very quickily. One way is to calculate sectional area with circular area, then times the thickness of the aluminum rolling. Another way is to use the outer diameter circular area to subtract the core area and then times the thickness of aluminum rolling.

- Q: What is the typical lead time for manufacturing aluminum coils?

- The typical lead time for manufacturing aluminum coils can vary depending on several factors such as the specific requirements of the order, the complexity of the manufacturing process, and the current demand and capacity of the manufacturer. In general, lead times for aluminum coil production can range from a few weeks to several months. For standard aluminum coil orders, where the specifications and quantities are within the manufacturer's regular production capabilities, the lead time is usually shorter and can be around 4-8 weeks. This includes the time required for raw material sourcing, processing, and quality control checks. However, for custom or specialized aluminum coil orders that require specific dimensions, finishes, or additional processing steps such as coating or embossing, the lead time can be longer. These types of orders may require additional time for design and engineering, tooling setup, and testing, which can extend the lead time to approximately 8-12 weeks or more. It is important to note that lead times can also be influenced by external factors such as the availability of raw materials, transportation delays, or unforeseen production issues. Therefore, it is always advisable to communicate with the manufacturer to get an accurate estimate of the lead time for specific aluminum coil orders.

- Q: Can aluminum coils be used in extreme temperature conditions?

- Yes, aluminum coils can be used in extreme temperature conditions. Aluminum has a high thermal conductivity and is resistant to corrosion, making it suitable for various temperature extremes. Additionally, aluminum's low melting point allows it to withstand high temperatures without deforming or losing its structural integrity.

- Q: Does anyone know of any men's deodorant that doesn't contain aluminum? It has to be strong, as I do sweat a lot.

- Go to old spice there the best

- Q: What are cold rolling aluminum coil and hot rolling aluminum coil? What are their features?

- If the rolling temperature is above the crystallization one, it is hot rolling, otherwise it is cold rolling.

Send your message to us

Ac Aluminum Coil Oxidation Mirror Finish Aluminium Coil for Building Materials

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords