China Diamond Embossed Aluminum Coil - Best Quality Prepainted Aluminum Coil Hot Demanded

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Aluminium Prepainted Coil Best Quality and Hot Demanded Description:

Aluminium Prepainted Coil Best Quality and Hot Demanded are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Prepainted Coil Best Quality and Hot Demanded:

1)High flexibility.

2)Impact resistance.

3)Excellent weather-proof durablity.

4)Anti-ultraviolet.

5)Hight erosion resist.

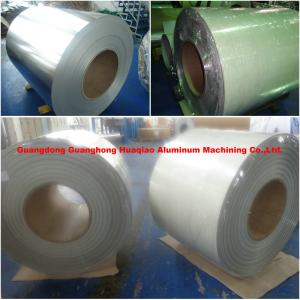

Images of Aluminium Prepainted Coil Best Quality and Hot Demanded:

Aluminium Prepainted Coil Best Quality and Hot Demanded Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: Are aluminum coils suitable for outdoor signage and displays?

- Indeed, outdoor signage and displays can indeed benefit from the use of aluminum coils. The reason for this is that aluminum is a material known for its exceptional durability and resistance to weather conditions, which makes it an ideal choice for outdoor applications. Its ability to withstand extreme temperature fluctuations, UV rays, moisture, and corrosion is well-known. Moreover, aluminum coils possess the advantage of being lightweight, yet still offering considerable strength, making them easy to handle and install. Furthermore, their versatility allows for easy shaping and forming into various sizes and designs. Additionally, aluminum boasts excellent printability, ensuring vibrant and long-lasting graphics. In summary, aluminum coils present a dependable and cost-effective solution for outdoor signage and displays.

- Q: What will be the pros and cons of using each of these materials?One thing to keep in mind is that aluminum alloys are good conductors of electricity.

- Alloy Ladders

- Q: How are aluminum coils used in HVAC systems?

- Aluminum coils are extensively used in HVAC (Heating, Ventilation, and Air Conditioning) systems for their excellent heat transfer properties and durability. These coils play a crucial role in the cooling process by efficiently removing heat from the air. In an HVAC system, aluminum coils are typically located in the condenser and evaporator units. The condenser coil is responsible for releasing heat to the surroundings by transferring it to the outdoor air, while the evaporator coil absorbs heat from indoor air, cooling it down. Aluminum is a preferred material for these coils due to its high thermal conductivity, which allows for efficient heat transfer. The coils are made of thin aluminum fins, which are attached to aluminum tubes. This design maximizes the surface area of the coil, enabling better heat exchange between the refrigerant flowing through the tubes and the air passing over the fins. During the cooling process, the refrigerant circulating through the coil absorbs heat from the indoor air, converting it into a gas. The heat is then transferred to the aluminum fins, where it is dissipated to the surrounding air. As a result, the air passing through the evaporator coil becomes cooler, creating a comfortable indoor environment. Similarly, in the condenser unit, the refrigerant releases heat to the outdoor air through the aluminum coils. This allows the refrigerant to return to its liquid state, ready to be cycled back to the evaporator coil for the cooling process to continue. Aluminum coils are also favored in HVAC systems for their resistance to corrosion, which ensures their longevity and reliability. They are lightweight, making them easier to handle during installation and maintenance. Additionally, aluminum coils are recyclable, contributing to a more sustainable and eco-friendly HVAC system. Overall, aluminum coils are an essential component of HVAC systems, providing efficient heat transfer, durability, and corrosion resistance. Their use significantly contributes to the cooling and comfort of indoor spaces.

- Q: Are aluminum coils suitable for architectural roofing systems?

- Yes, aluminum coils are suitable for architectural roofing systems. Aluminum is lightweight, durable, and corrosion-resistant, making it an excellent choice for roofs. It can withstand harsh weather conditions, is easy to work with, and offers a range of design possibilities. Additionally, aluminum coils are available in a variety of colors and finishes, allowing for customization and enhancing the aesthetic appeal of architectural roofing systems.

- Q: How are aluminum coils protected against mechanical damage?

- Aluminum coils are protected against mechanical damage through various methods such as applying protective coatings, using durable outer casings, employing edge guards, and ensuring proper handling during transportation and installation.

- Q: Can aluminum coils be used in the production of signage?

- Indeed, signage production can make use of aluminum coils. Aluminum, being a versatile and durable material, finds widespread use in the signage industry because of its lightweight characteristic, resistance to corrosion, and ability to endure diverse weather conditions. The malleability of aluminum coils allows for easy shaping, cutting, and forming into various sizes and shapes, thereby making it an excellent choice for creating personalized signage. Moreover, aluminum coils can be coated with different finishes, including paint or powder coating, to improve their appearance and offer additional protection against fading and scratching. All things considered, aluminum coils are highly favored for signage production due to their adaptability, resilience, and aesthetic charm.

- Q: Can aluminum coils be used in solar energy systems?

- Yes, aluminum coils can be used in solar energy systems. Aluminum is a commonly used material in the construction of solar panels and other components due to its lightweight, corrosion resistance, and excellent thermal conductivity properties. It is often used as a conductor in the wiring of solar panels and can also be found in heat exchangers and solar water heaters.

- Q: How do aluminum coils perform in cryogenic environments?

- Aluminum coils generally perform well in cryogenic environments due to their low thermal expansion coefficient and high thermal conductivity. When exposed to extremely low temperatures, aluminum coils exhibit minimal contraction and expansion, making them suitable for use in cryogenic applications. The low thermal expansion coefficient ensures that the coils maintain their structural integrity and do not deform or crack under extreme temperature fluctuations. Additionally, aluminum's high thermal conductivity allows for efficient heat transfer, enabling the coils to dissipate excess heat and maintain a stable temperature within the cryogenic environment. Overall, aluminum coils are a reliable choice for use in cryogenic environments and can effectively withstand the challenges posed by extremely low temperatures.

- Q: How are aluminum coils processed and shaped into different forms?

- Aluminum coils are processed and shaped into different forms through a series of manufacturing processes. First, the coils are uncoiled and fed into a machine where they are cleaned, removing any dirt or impurities. Then, the coils are passed through a series of rollers that apply pressure to shape the aluminum into the desired form, such as sheets, plates, or foils. Additional processes like annealing, cutting, and bending may be applied to further shape the aluminum. Finally, the formed aluminum is typically subjected to surface treatments, such as anodizing or coating, to enhance its durability or appearance.

- Q: What is the maximum coil width available?

- The maximum available coil width is contingent upon various factors, including the manufacturing capabilities of the supplier or manufacturer in question. In broad terms, coil widths can span from a few millimeters to several meters. The utmost width is typically dictated by the machinery employed in coil production and the constraints imposed by the size of the raw materials being handled. It is advisable to engage in consultation with specific suppliers or manufacturers to ascertain the maximum coil width feasible for a given product or application.

Send your message to us

China Diamond Embossed Aluminum Coil - Best Quality Prepainted Aluminum Coil Hot Demanded

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords