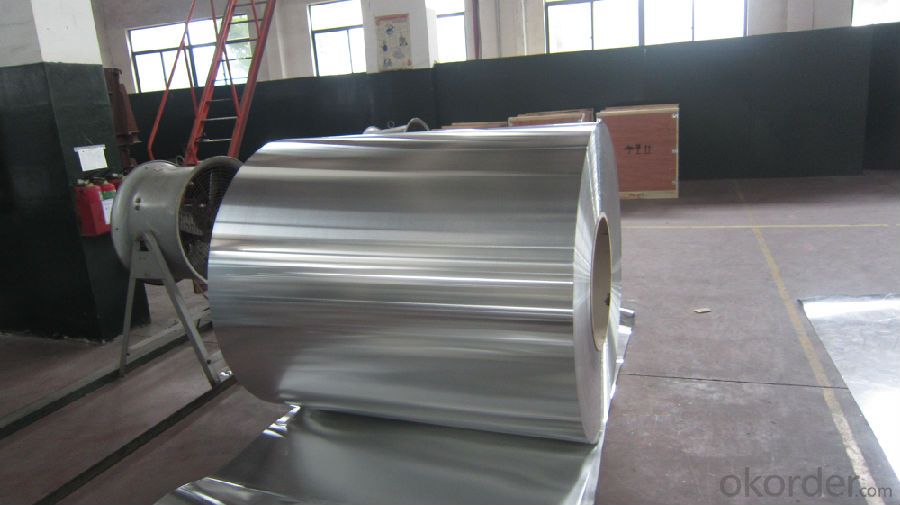

Aluminuim Coil 1060 1100 1200 O Aluminum Strip Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1) alloy number 1050 1060 1100 1200 3003 5052 5754 6061 8011.

2) temper available O H12 H14 H16 H18.

3) application: decoration, interior wall

4) thickness: 0.15--2mm

5) width: 2200mm max

6) production treatment: cold rolled or hot rolled.

7) surface appearance: flat clean surface no whole, scratch, oil dirty and oxidation.

8) cutting edge: neat cutting edge no burrs.

Chemistry Composition & Mechanical Properties

alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al |

1050 | 0.250 | 0.400 | 0.050 | 0.050 | 0.050 | - | 0.050 | 0.030 | 99.5 |

1060 | 0.250 | 0.350 | 0.050 | 0.030 | 0.030.- | - | 0.050 | 0.030 | 99.6 |

1070 | 0.200 | 0.250 | 0.040 | 0.030 | 0.030 | - | 0.040 | 0.030 | 99.7 |

1100 | Si+Fe:0.95 | 0.05-0.2 | 0.050 | - | - | 0.100 | - | 99.0 | |

FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

- Q:Supposably water ozidies it what ever that means so how in the world do i clean an aluminum bike if i cant use water? i like to use water and soap on my carbon bike so what do i use on a aluminum?

- You can use water and soap. Aluminum does not rust and will not be harmed by water. Happy washing

- Q:What is the typical electrical resistivity of aluminum coils?

- The typical electrical resistivity of aluminum coils is approximately 2.65 x 10^-8 ohm-meters. Aluminum is known for its low resistivity, making it an excellent choice for electrical conductors. The low resistivity allows for efficient transfer of electric current through the coils, minimizing energy loss and heat generation. This property makes aluminum coils widely used in various electrical applications, such as transformers, motors, and generators.

- Q:Can aluminum coils be used in the production of aluminum downspouts?

- Yes, aluminum coils can be used in the production of aluminum downspouts. Aluminum coils are commonly used in the manufacturing process of downspouts as they can be easily formed and shaped into the desired downspout design. The flexibility and durability of aluminum make it an ideal choice for downspout production, ensuring longevity and resistance to corrosion.

- Q:Can aluminum coils be used for radiation shielding?

- Indeed, radiation shielding can be accomplished using aluminum coils. Owing to its substantial atomic number and density, aluminum is frequently employed as a radiation shielding material, demonstrating remarkable proficiency in absorbing and dispersing radiation. It effectively safeguards against an extensive spectrum of radiation varieties, encompassing gamma rays and X-rays. Moreover, aluminum possesses the advantageous qualities of being lightweight and pliable, rendering it convenient to manipulate and appropriate for a wide range of situations necessitating radiation shielding. These encompass domains such as medical imaging, nuclear power plants, and the aerospace industry.

- Q:I am trying to electropolish the surface of a 3003 aluminum sample to analyze in the SEM. I was wondering if anyone knew what electrolyte and electropolishing paramaters work for this alloy. So far I have used phosporic+ethanol+water at 50V for 2 minutes with minimal success.

- Aluminium needs deoxidizing also called as desmutting after electropolishing. This is done in a hot chromic acid bath for nearly for 5 minutes.

- Q:What are the common installation methods for aluminum coils?

- The common installation methods for aluminum coils include direct attachment, concealed fastening, and interlocking panel systems.

- Q:How are aluminum coils used in the production of automotive parts?

- Aluminum coils play a crucial role in the production of automotive parts. Due to their lightweight and corrosion-resistant properties, aluminum coils are extensively used in the manufacturing of various automotive components. One of the main applications of aluminum coils in the automotive industry is in the production of body panels. These coils are processed into sheets, which are then formed and shaped into body panels such as hoods, doors, fenders, and roofs. The lightweight nature of aluminum helps to reduce the overall weight of the vehicle, resulting in improved fuel efficiency and better handling. Aluminum coils are also used in the production of heat exchangers for automotive air conditioning systems and radiators. The excellent thermal conductivity of aluminum allows for efficient heat transfer, ensuring optimal cooling performance. This helps to maintain the desired temperature in the vehicle's interior and prevent engine overheating. Additionally, aluminum coils are utilized in the production of various engine components. They are widely used in the manufacturing of cylinder heads, engine blocks, and intake manifolds. The high strength-to-weight ratio of aluminum makes it an ideal material for these applications, as it provides strength and durability while reducing the overall weight of the engine. Moreover, aluminum coils are used in the production of suspension components such as control arms and subframes. The lightweight nature of aluminum allows for better suspension performance, resulting in improved handling and a smoother ride. In summary, aluminum coils are extensively used in the production of automotive parts due to their lightweight, corrosion-resistant, and high-strength properties. They are employed in the manufacturing of body panels, heat exchangers, engine components, and suspension parts, contributing to the overall performance, efficiency, and durability of vehicles.

- Q:Can aluminum coils be used for food processing conveyor systems?

- Yes, aluminum coils can be used for food processing conveyor systems. Aluminum is a durable and lightweight material that is resistant to corrosion, making it suitable for food processing environments. Additionally, aluminum is non-toxic and does not react with food, ensuring the safety and quality of the processed products.

- Q:actually pollute more than the process of extracting it from earth and producing new aluminum?I saw a report about 5 years ago on this and was wondering if anyone else had info on this subject.

- Aluminum recycling is very cost-effective. Unlike most materials, metal recycling pollutes less than producing new product because most of the pollution is created by mining and smelting ore.

- Q:What is the maximum width of aluminum coils?

- The maximum width of aluminum coils can vary depending on the specific manufacturer and application, but it typically ranges from 60 inches to 96 inches.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminuim Coil 1060 1100 1200 O Aluminum Strip Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords