Mastic PVDF Coated Aluminum Coil - Mill Finished from China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

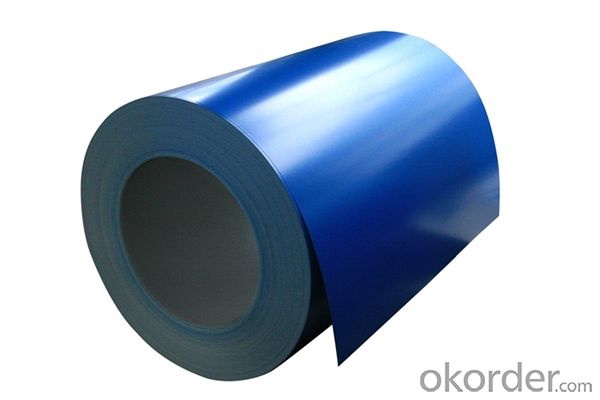

1. Structure of Mill Finished PVDF Coating Aluminium Coil from China Description

Mill Finished PE Coating Aluminium Coil is one semi-finished aluminium material. This coil can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of Mill Finished PVDF Coating Aluminium Coil from China

Mill Finished PE Coating Aluminium Coil | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

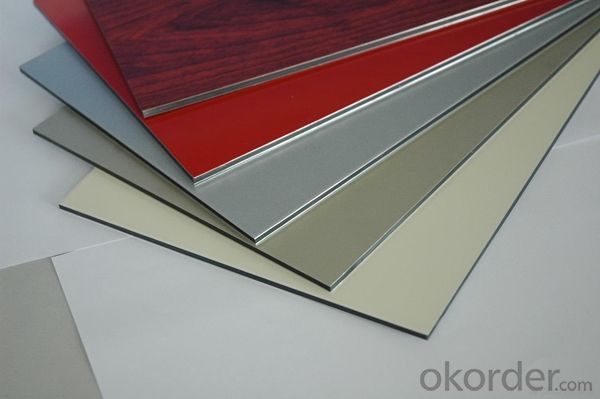

3. Application of Mill Finished PVDF Coating Aluminium Coil from China

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of Mill Finished PVDF Coating Aluminium Coil from China

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of Mill Finished PVDF Coating Aluminium Coil from China

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

6. Image of Mill Finished PVDF Coating Aluminium Coil from China

7. Package and shipping of Mill Finished PVDF Coating Aluminium Coil from China

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Can aluminum coils be used in the production of heat exchanger fins?

- Yes, aluminum coils can be used in the production of heat exchanger fins.

- Q: This question asks for methods to assess the quality of aluminum coil, which is important in industries where aluminum products are used.

- <p>To check the quality of aluminum coil, you should inspect its surface for any defects like scratches, dents, or discoloration. Measure its thickness and width to ensure they meet the specified standards. Test its mechanical properties, such as tensile strength and elongation, to verify its strength and flexibility. Conduct a chemical analysis to confirm the alloy composition and purity. Check for any impurities or inclusions that could affect performance. Finally, assess the coil's flatness and straightness to ensure it's suitable for further processing.</p>

- Q: What precautions should be taken while using tools for handling aluminum coils?

- <p>When handling aluminum coil tools, it's crucial to follow safety measures to prevent accidents. Always wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and closed-toe shoes. Ensure the tools are in good condition and well-maintained. Keep the work area clean and free of debris to avoid slips or trips. Be cautious of sharp edges on the aluminum coils, as they can cause cuts. Use lifting equipment when necessary and never attempt to lift heavy coils manually. Follow all manufacturer guidelines for the safe operation of the tools. Regularly inspect the tools for any signs of wear or damage and replace them as needed.</p>

- Q: Can aluminum coils be used in HVAC heat exchangers?

- Yes, aluminum coils can be used in HVAC heat exchangers. Aluminum is a commonly used material in heat exchangers due to its excellent thermal conductivity, lightweight nature, and resistance to corrosion. It allows for efficient heat transfer and is often preferred over other materials like copper in certain HVAC applications.

- Q: What are the different alloys used for aluminum coils?

- There are several different alloys used for aluminum coils, including 1100, 3003, 5052, and 6061. Each alloy has its own unique properties and characteristics, making them suitable for various applications. For example, 1100 is often used for chemical and food processing equipment, while 3003 is commonly used in heat exchangers and cooking utensils. 5052 is known for its high corrosion resistance and is often used in marine and transportation industries. Lastly, 6061 is a versatile alloy used in structural components, aerospace applications, and automotive parts.

- Q: I don't know, I see a metal is a metal. I understand that a bike shop bike has better service and the bike has better components. Yet I just feel the frame of a $500 bike store bike and a $100 bike from Walmart using aluminum is the same. It's like people charging $100 for audio/video cables when a $1 no-name cable works the same for tv. Is this the same marketing ploy in the bike industry?I see a Mongoose bike for $500 to $1000 on their website, yet I see one with the same frame metal at Walmart/Kmart for only $100. Mongoose is a reputable name. What gives?What do you think? Is the metal quality in a $500 aluminum bike shop bike the same as a $100 aluminum department store bike?

- Aluminum Mountain Bike

- Q: How are aluminum coils protected against transportation damage?

- The prevention of transportation damage to aluminum coils is ensured by manufacturers and transportation companies through various measures. Primary among these measures is the packaging and storage of the coils in robust crates or pallets, which act as a barrier against external impact and guarantee stability during transit. These crates, which are typically constructed from wood or metal, are specifically designed to withstand the challenges of transportation. To provide further protection against damage, the coils are often enveloped in protective materials like plastic or stretch film. This supplementary layer of packaging serves to prevent scratches, abrasions, and moisture damage that may occur during handling and transportation. In addition, the coils are frequently secured within the crates or pallets using straps or bands, thereby averting any potential movement or collision with other objects. In order to create a cushioning effect within the packaging, manufacturers frequently employ padding materials such as foam or cardboard inserts. These inserts absorb shock and vibration during transit, thereby reducing the likelihood of damage caused by impacts or sudden movements. Transportation companies also play a critical role in ensuring the secure transportation of aluminum coils. They utilize specialized handling equipment, such as forklifts or cranes, to minimize the risk of mishandling and dropping the coils. Furthermore, they meticulously load and secure the coils within shipping containers or trucks, ensuring proper bracing and immobilization to prevent shifting or rolling during transportation. In conclusion, the protection of aluminum coils from transportation damage is achieved through the utilization of robust packaging, protective wraps, padding materials, and appropriate handling techniques. These measures aim to minimize the risk of scratches, dents, and other forms of damage caused by impacts, vibrations, or mishandling during transit.

- Q: This question asks for a comparison of the pros and cons of utilizing steel coils in construction projects.

- <p>Advantages of using steel coils in construction include their high strength and durability, which allows for the creation of robust structures. They are also resistant to corrosion and can withstand harsh weather conditions. Steel coils are versatile and can be easily shaped and welded, making them suitable for a variety of construction applications. Additionally, they are recyclable, contributing to sustainability efforts. Disadvantages include the initial high cost of steel coils compared to some other materials, and the potential for rust if not properly maintained. Steel structures may also require more frequent inspections and maintenance due to the risk of corrosion over time, especially in coastal or humid environments.</p>

- Q: Are there any restrictions on the export or import of aluminum coils?

- Yes, there are restrictions on the export or import of aluminum coils. These restrictions can vary from country to country and are typically imposed to protect domestic industries, ensure national security, or comply with international trade agreements. Governments may impose import or export duties, quotas, licensing requirements, or impose restrictions on certain countries for political or economic reasons. It is important to consult the specific regulations and trade policies of the countries involved to understand the exact restrictions in place.

- Q: What are the potential applications of recycled aluminum coils?

- Recycled aluminum coils have various potential applications across several industries. They can be used in the manufacturing of automotive parts, such as body panels, engine components, and heat exchangers. Additionally, they can be utilized in the production of building materials like roofing, gutters, and siding due to their corrosion resistance and durability. Moreover, recycled aluminum coils are suitable for packaging purposes, including beverage cans, food containers, and aerosol cans. Their versatility and sustainability make them an excellent choice for a wide range of applications.

Send your message to us

Mastic PVDF Coated Aluminum Coil - Mill Finished from China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords