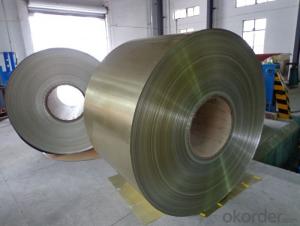

Copper Colored Mill Finished and Color Coated Aluminum Coil for Display Platforms

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Mill Finished And Color Coated Aluminium Coil For Display Platforms

Description

Alloy | 1060, 1100, 3003, 8011, etc. |

Temper | H16, H18, H24, H26, H28 |

Thickness | From 0.05mm to 3.0mm |

Width | Standard width:1240mm |

Special width:1300mm, 1520mm, 1570mm, 1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, ACRYLIC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness(pencil resistance) | More than 2h |

Coating adhesion | 5J (EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility(T-bend) | 2T |

MEK resistance | More than 100 |

Advantage | 1.High temperature resistant 2.Weathering resistant 3.Scrubbing resistant 5.Acid or alkali proof 6. Fireproof 7.Light weight material is easy to construct and install |

Out package | Wooden splint with export standard |

Application | ACP, wall cladding, facades, roofs and canopies, ceilings, signboards, blind window, display platforms, electrical panels, etc |

FAQ

--Q: Do you provide free samples?

--A: Yes, free samples will be sent to you on freight at destination.

--Q: Can I get your latest products catalogue?

--A: Yes, it will be sent to you in no time.

--Q: What is the MOQ?

--A: 2 tons

--Q: What are your payment terms?

--A: We accept L/C, T/T.

--Q: What kinds of alloy can you supply?

--A: 1000 series: 1050, 1060, 1070, 1100, 1145, 1200

3000 series: 3003, 3004, 3105, 3104

5000 series: 5052, 5083, 5754, 5182

6000 series: 6061, 6063, 6062, 6063

8000 series: 8011, 8021

--Q: What kinds of temper can you supply?

--A: O-H112: O,H12,H14,H16,H18,H22,H24,H26,H,32,H34,H111,H112

T3, T4, T6

- Q: What are the typical applications of aluminum coils in the automotive industry?

- Due to their advantageous properties, aluminum coils are widely utilized in various applications within the automotive industry. One particular use is in the manufacturing of heat exchangers, like radiators and condensers, which greatly benefit from aluminum's high thermal conductivity. This allows for efficient heat transfer, which in turn enhances the cooling efficiency of both the vehicle's engine and air conditioning system. Another common application of aluminum coils in the automotive sector involves constructing lightweight body panels and structural components. Aluminum's low density is well-known for reducing the overall weight of vehicles, resulting in improved fuel efficiency and reduced emissions. Additionally, the high strength-to-weight ratio of aluminum makes it an ideal material for impact-absorbing structures, thus enhancing vehicle safety. Aluminum coils are also extensively used in the production of electrical wiring systems and connectors in automobiles. Its excellent electrical conductivity enables efficient transmission of electrical signals throughout the vehicle. Furthermore, aluminum's corrosion resistance properties make it suitable for use in various weather conditions. Furthermore, aluminum coils are also employed in the production of suspension systems, including control arms and knuckles. The stiffness and durability of aluminum contribute to enhanced handling and responsiveness, ultimately resulting in improved driving dynamics. In conclusion, aluminum coils find typical applications in the automotive industry, including heat exchangers, lightweight body panels, electrical wiring systems, and suspension components. These applications effectively utilize the advantageous properties of aluminum, such as high thermal conductivity, low density, excellent electrical conductivity, and corrosion resistance.

- Q: Can aluminum coils be used in the production of aluminum sandwich panels?

- Aluminum sandwich panels can indeed utilize aluminum coils. Typically, these coils serve as the outer skins or facings of the panels. To enhance their durability, resistance to corrosion, and aesthetic appeal, the coils undergo initial processing and coating. This process ensures that they possess the desired qualities. Subsequently, they are bonded with a core material, such as polyethylene or mineral wool, to create a sandwich panel structure that is both lightweight and rigid. The inclusion of aluminum coils provides the panels with exceptional mechanical properties, including a high strength-to-weight ratio, flexibility, and thermal conductivity. Moreover, the use of aluminum coils enables convenient customization as they can be formed, shaped, and painted to meet specific design and specification requirements.

- Q: Is it possible to use aluminum coils for storage purposes?

- <p>Yes, aluminum coils can be used for storage, particularly for certain applications. They are often used in HVAC systems and electrical wiring due to their conductivity and flexibility. For general storage, aluminum coils may be suitable for winding and storing cables, wires, or similar materials. However, for storing items that require a specific environment or have weight concerns, it's important to consider the coil's strength and whether it can provide the necessary support and protection. Always ensure that the storage method complies with safety standards and the material's properties.</p>

- Q: Is it safe and effective to heat an aluminum coil using a microwave oven?

- <p>No, you should not use a microwave to heat an aluminum coil. Microwaves can cause aluminum to heat unevenly and potentially spark, which is dangerous. Aluminum is a good conductor of electricity and can reflect microwaves, leading to arcing and fire hazards. Always use microwave-safe materials when heating food or other substances in a microwave.</p>

- Q: Can aluminum coils be used for food storage and processing?

- Yes, aluminum coils can be used for food storage and processing. Aluminum is a popular choice for food storage and processing due to its many beneficial properties. It is lightweight, strong, and resistant to corrosion, which makes it ideal for maintaining the quality and freshness of food. Aluminum coils can be used to manufacture various food storage and processing equipment such as containers, pans, trays, and foil. Additionally, aluminum has excellent thermal conductivity, which allows for efficient cooling and heating of food. It is also impermeable to light, moisture, and oxygen, which helps to protect food from spoilage and contamination. Overall, aluminum coils are a reliable and safe option for food storage and processing applications.

- Q: What is the maximum width and thickness of aluminum coils?

- The maximum width and thickness of aluminum coils vary depending on the specific grade and manufacturing capabilities. However, as a general guideline, aluminum coils can range in width from a few inches to several feet, while thickness can range from a few millimeters to several inches. It is important to consult the manufacturer or supplier for precise specifications based on the intended application.

- Q: Are aluminum coils resistant to impact damage?

- Yes, aluminum coils are generally resistant to impact damage. Aluminum is a lightweight and durable material that can withstand minor impacts without getting damaged. However, excessive force or strong impacts may still cause damage to the coils.

- Q: What are the various surface finishes available for aluminum coils?

- Aluminum coils offer a variety of surface finishes to meet different needs and preferences. The options include: 1. Mill Finish: This is the most basic and natural finish achieved by passing the coil through rollers during manufacturing. It gives the aluminum a smooth, shiny appearance. 2. Anodized Finish: Anodizing is an electrochemical process that adds a protective layer to the aluminum coil's surface. It comes in various colors and provides enhanced resistance to corrosion, abrasion, and wear. Architects commonly use anodized finishes. 3. Painted Finish: Aesthetic appeal and environmental protection can be achieved by coating aluminum coils with paint. The paint comes in different colors and finishes, such as matte, glossy, or metallic. 4. Brushed Finish: By brushing the surface with abrasive materials, aluminum coils can have a textured appearance with fine lines or scratches. Brushed finishes are often used for decorative purposes. 5. Polished Finish: Buffing the surface of the aluminum coil creates a smooth, reflective finish. It gives a mirror-like appearance and is commonly used for decorative and architectural applications. 6. Embossed Finish: Embossing involves stamping or pressing a pattern or design onto the surface of the aluminum coil. This finish adds texture and depth, making it suitable for non-slip surfaces or decorative purposes. 7. Laminated Finish: Lamination involves bonding a thin layer of film or foil to the aluminum coil's surface. This finish provides additional protection against scratches, stains, or UV radiation. It is commonly used for applications that require durability and resistance. These examples highlight the range of surface finishes available for aluminum coils. The choice of finish depends on specific application requirements, desired appearance, and functional properties needed for the end product.

- Q: where's the best place to look for aluminum not cans

- It depends on what you will use it for. If you are just looking for scrap aluminum to be melted down, cars radiators a full of aluminum. Otherwise, maybe check with a local metal fabricator and see if you could buy some of their drop.

- Q: Are aluminum coils fire-resistant?

- Yes, aluminum coils are fire-resistant. Aluminum has a high melting point of 660 degrees Celsius (1220 degrees Fahrenheit) and it does not burn, making it a non-combustible material. This property makes aluminum coils suitable for various applications where fire resistance is a critical factor, such as in building construction, electrical wiring, and HVAC systems. Additionally, aluminum's excellent heat conductivity helps dissipate heat quickly, reducing the risk of fire. However, it is important to note that while aluminum coils themselves are fire-resistant, they may be used in systems that include other components which may not have the same level of fire resistance. It is important to consider the entire system and follow proper fire safety regulations and guidelines to ensure overall fire safety.

Send your message to us

Copper Colored Mill Finished and Color Coated Aluminum Coil for Display Platforms

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords