Hindalco Aluminum Sheets - Mill Finished Aluminum Coil Alloy AA1xxx for Building Outer Doors

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Mill Finished Aluminum Coil Alloy AA1XXX for Building Ourter Doors

ALLOY | AA1050 AA1060 AA1070 AA1100 ETC AA3003 AA3004 AA3005 AA3104 AA3105 ETC AA5005 AA5052 AA5083 AA5754 ETC |

TEMPER | H14,H18,H24,H26,H32 |

THICKNESS | 0.2MM-20MM |

WIDTH | 10mm-1500mm |

COIL WGT | 2Mt - 3Mt |

Coil ID | 20" |

SURFACE | Mill finished etc |

STANDARD | GB/T 3880-2006 |

2. Application of Mill Finished Aluminum Coil Alloy AA1XXX for Building Ourter Doors

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Mill Finished Aluminum Coil Alloy AA1XXX for Building Ourter Doors

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

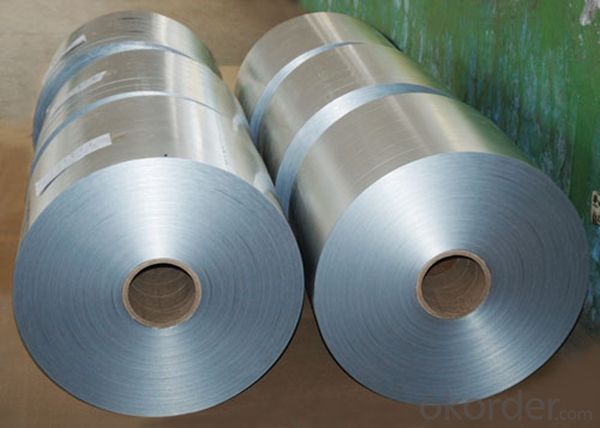

5. Image of Mill Finished Aluminum Coil Alloy AA1XXX for Building Ourter Doors

6. Package and shipping of Mill Finished Aluminum Coil Alloy AA1XXX for Building Ourter Doors

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: I am trying to find away of turning aluminum oxide or alumina into just aluminum. Please post all ideas i dont care how crazy.

- ensure u have distilled water cuz if there is salt in it, u might finally end up freeing chlorine interior the air and die. haha. ok, take a 9 -12 volt battery or something like that and placed 2 wires from the positve and unfavourable ends interior the water. the only cord that bubbles extra is the hydrogen. so turn a attempt tube and placed it interior the water and so as that there is not any air interior the attempt tube. whilst the cord is going in, the hydrogen will fill it up and u'll be left with organic hydrogen interior the tube. i don't be conscious of if i defined it perfect yet there are a team of video clips on youtube. examine them out.

- Q: What is the typical machinability of aluminum sheets?

- The typical machinability of aluminum sheets is considered to be excellent. Aluminum is known for its softness and low density, which makes it relatively easy to machine. It can be cut, drilled, and formed with relative ease, allowing for efficient and precise machining processes. However, the specific machinability of aluminum sheets can vary depending on factors such as alloy composition, temper, and thickness.

- Q: Can aluminum sheets be an alternative to glass in certain applications?

- Yes, aluminum sheets can be an alternative to glass in certain applications. Aluminum is lightweight, durable, and has excellent corrosion resistance, making it suitable for outdoor and industrial applications where glass may be prone to breakage or damage. Additionally, aluminum sheets can provide better insulation and soundproofing properties compared to glass. However, it is important to consider specific requirements and limitations of each application before choosing aluminum sheets as an alternative to glass.

- Q: Are aluminum sheets suitable for aerospace wing structures?

- Yes, aluminum sheets are often used in aerospace wing structures due to their lightweight nature, high strength-to-weight ratio, and excellent corrosion resistance.

- Q: Are aluminum sheets suitable for reflective signage?

- Indeed, reflective signage can effectively utilize aluminum sheets. This adaptable material is frequently employed for such signs because of its resilience, lightness, and capacity to reflect light. With a noteworthy reflectivity index, aluminum proves itself ideal for situations where visibility is of utmost importance, such as road signs, traffic signs, and safety signs. By applying reflective films or paints to aluminum sheets, their reflective properties can be further enhanced, guaranteeing optimal visibility even in dimly lit environments. Furthermore, aluminum's resistance to weathering, corrosion, and fading ensures that it remains a durable and economical option for reflective signage in the long run.

- Q: I need to fix some connections at my dad's house. The original wiring is aluminum, but the newer stuff he did is copper. Simple wire nuts will not suffice. Already had one melted one. I need to fix the connections, but need an economical, safe way of doing it. Suggestions?

- You need both anti-oxide paste, (follow directions), and spring type connectors to take care of the thermal creep.- A good electrical supply hose will have them. Give them the details and they'll advise you. (Last I heard, modern wirenuts are ' UL listed' for the application. Lack of the surface treatment is probaly the cause of your bad connection.) Aluminum wiring isn't bad by itself. It's the terminations that cause the problems. Bad advice Shabir - Screw connectors have no 'spring' to take up the thermal cycles of the aluminum and are exactly the WRONG thing to use for the problem in question.

- Q: Are aluminum sheets resistant to vibration?

- Yes, aluminum sheets are generally resistant to vibration due to their inherent strength and durability. The high stiffness-to-weight ratio of aluminum, along with its ability to dampen vibrations, makes it an ideal material for applications requiring vibration resistance.

- Q: Can aluminum sheets be hydroformed?

- Yes, aluminum sheets can be hydroformed.

- Q: Explain the distinctions between aluminum and steel sheets in terms of their properties and applications.

- <p>Aluminum sheets and steel sheets differ in material composition, weight, strength, and applications. Aluminum sheets are lightweight, corrosion-resistant, and have good thermal conductivity, making them ideal for applications requiring light weight and resistance to corrosion. Steel sheets, on the other hand, are heavier, stronger, and more durable, suitable for structural applications where high strength is required. Steel is also magnetic, which aluminum is not, and has a higher melting point. However, steel is more prone to rust compared to aluminum, which requires protective coatings or treatments in many applications.</p>

- Q: Can aluminum sheets be bent?

- Yes, aluminum sheets can be bent as they have malleable properties that allow them to be easily shaped or formed into desired angles or curves.

Send your message to us

Hindalco Aluminum Sheets - Mill Finished Aluminum Coil Alloy AA1xxx for Building Outer Doors

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords