Welding Aluminum Sheets - AA1XXX Coated Aluminum Coils for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of AA1xxx Coated Aluminum Coils Used for Construction Description

AA1xxx Coated Aluminum Coils Used for Construction are of a wide range of colors, which give wonderful appearance no matter in residential and commercial constructions or great exhibition centers.

AA1xxx Coated Aluminum Coils Used for Construction have been widely used in the fields of construction and decoration, electronic applications, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

2.Main Features of AA1xxx Coated Aluminum Coils Used for Construction

1)Excellent weather-proof durability

2)Anti-ultraviolet

3)High erosion resistance

4)Stable color and gloss

5)Good mechanical processing performance

6)Abrasion resistance

7)Anti-impact

8)High flexibility

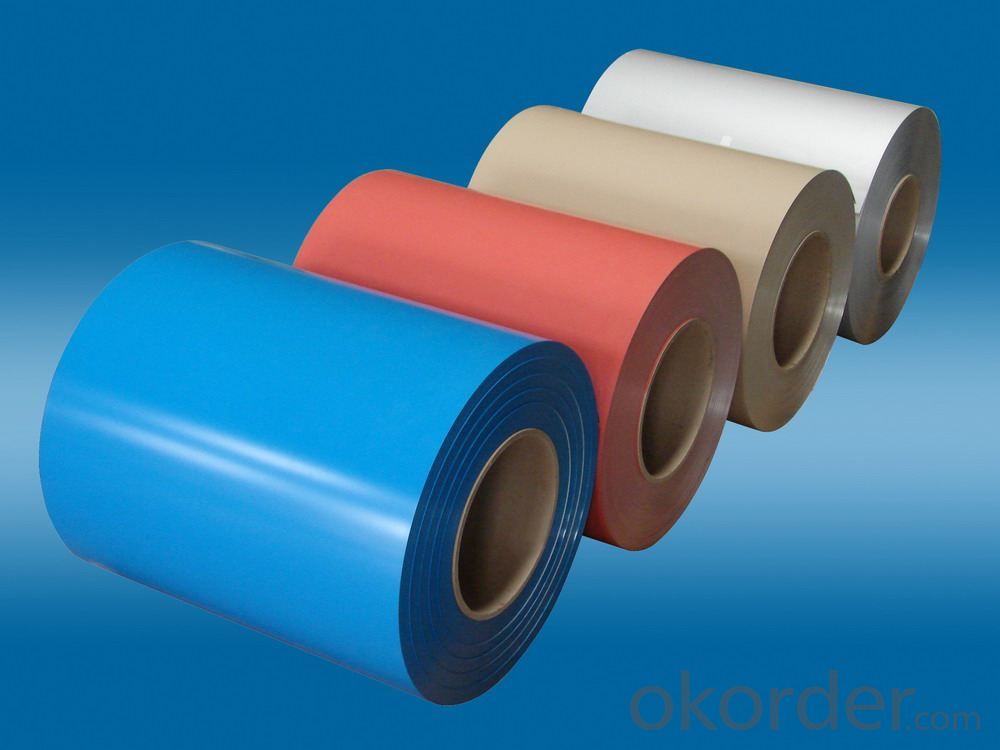

3.AA1xxx Coated Aluminum Coils Used for Construction Images

4. AA1xxx Coated Aluminum Coils Used for Construction Specification

Alloy | AA1xxx |

Temper | H14,H16,H18,H22,H24,H26,H32,O/F |

Thickness | 0.03mm-3.0mm |

Width | 30mm-1700mm |

Coating | PE,PVDF,Epoxy |

Painting Thickness | Standard 16-25 Mic, max 40 Mic |

Color | According to RAL colors or customers' samples |

Standard | GB/T 17748-1999 |

5. FAQ of AA1xxx Coated Aluminum Coils Used for Construction

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: This question asks about the various types of aluminum sheets that are commonly used for roofing purposes, including their specific applications and characteristics.

- <p>Aluminum sheets used for roofing come in various types, each with unique properties and applications. The main types include: 1) Corrugated Aluminum Sheets: Known for their strength and durability, these are often used in commercial and industrial roofing due to their ability to withstand harsh weather conditions. 2) Standing Seam Aluminum Sheets: These provide a sleek, clean look and are favored for their water-resistant properties, making them ideal for residential and architectural applications. 3) Flat Aluminum Sheets: Offer a smooth surface finish and are used where a uniform appearance is desired. 4) Perforated Aluminum Sheets: These have small holes that allow for ventilation, reducing heat build-up and are used in areas requiring natural light and air circulation. 5) Embossed Aluminum Sheets: With a textured surface, they provide added rigidity and are used in both residential and commercial settings for their aesthetic appeal. Each type is chosen based on the specific needs of the roofing project, such as design, weather resistance, and longevity.</p>

- Q: What are the different finishes available for aluminum sheets?

- There are several different finishes available for aluminum sheets, each with its own unique characteristics and benefits. Some of the most common finishes include: 1. Mill finish: This is the most basic finish for aluminum sheets, characterized by a smooth, shiny surface. It is typically achieved by passing the aluminum through a rolling mill, leaving it with a natural appearance. Mill finish is often preferred for industrial applications where aesthetics are not a primary concern. 2. Anodized finish: Anodizing is an electrochemical process that adds a layer of oxide to the surface of the aluminum sheet, providing enhanced durability and corrosion resistance. Anodized finishes can range from clear to various colors, and they can also be dyed to achieve specific hues. 3. Brushed finish: This finish is achieved by brushing the aluminum sheet with abrasive materials, creating a pattern of fine lines on the surface. Brushed finishes offer a distinctive, textured appearance and are commonly used in architectural and decorative applications. 4. Polished finish: Polishing aluminum sheets involves buffing the surface to a high shine, resulting in a mirror-like, reflective finish. This finish is often chosen for decorative purposes, such as in interior design, automotive detailing, or jewelry making. 5. Embossed finish: Embossing involves creating raised patterns or designs on the surface of the aluminum sheet, adding texture and visual interest. It can be achieved through various methods, such as roll embossing or stamping, and is commonly used for decorative purposes or to improve grip on certain applications. 6. Powder-coated finish: Powder coating is a process where a dry powder is applied to the aluminum sheet and then cured under heat, creating a tough, durable, and attractive finish. Powder-coated finishes come in a wide range of colors and provide excellent resistance to fading, chipping, and scratching. These are just a few examples of the different finishes available for aluminum sheets. The choice of finish will depend on the specific requirements of the application, such as aesthetics, durability, and functionality.

- Q: What is the hardness rating of 101 aluminum sheets?

- The hardness of 101 aluminum sheets can vary due to various factors, including alloy composition, heat treatment, and manufacturing processes. Generally, aluminum alloys are considered to have relatively low hardness compared to other metals. While the Rockwell hardness scale is commonly used for measuring metal hardness, it is not typically used for aluminum. Instead, the Brinell or Vickers hardness tests are more commonly employed for aluminum alloys. Without detailed information regarding the alloy composition and specific heat treatment applied to the 101 aluminum sheets, it is challenging to provide an exact hardness rating. Therefore, it is advised to consult the manufacturer or supplier of the specific 101 aluminum sheets to obtain accurate hardness information.

- Q: What are the different surface patterns available for aluminum sheets?

- Aluminum sheets can have various surface patterns depending on the desired aesthetic and functional requirements. Some common surface patterns available for aluminum sheets include: 1. Smooth Finish: This is the most basic surface pattern, characterized by a flat and polished appearance. It is often used for applications where a clean and sleek appearance is desired, such as in architecture and interior design. 2. Stucco Embossed: This surface pattern features a raised texture resembling the look of stucco. It provides enhanced durability and slip resistance, making it suitable for applications that require a non-slip surface, such as stair treads or ramps. 3. Diamond Tread: This pattern consists of raised diamonds on the surface, providing superior traction and slip resistance. It is commonly used in applications where safety is a concern, such as on vehicle running boards or industrial flooring. 4. Hammered Finish: This surface pattern creates a textured appearance similar to that of hammered metal. It adds visual interest and can be used to enhance the aesthetics of architectural elements, decorative panels, or furniture. 5. Brushed Finish: Also known as satin finish, this pattern is achieved by brushing the surface of the aluminum sheet in a linear direction. It creates a smooth and consistent texture, often used for decorative purposes in applications like signage, wall cladding, or kitchen appliances. 6. Perforated: In this pattern, the aluminum sheet is punctured with small holes or slots in a specific design or pattern. It allows for airflow, light transmission, and sound absorption, making it suitable for applications like ventilation systems, acoustic panels, or decorative screens. These are just a few examples of the different surface patterns available for aluminum sheets. The choice of pattern depends on the intended use, desired appearance, and functional requirements of the application.

- Q: I broke the swing-arm of a cut-off saw, need to know how to weld it back. I have a stick welder and can weld steel, but have never messed with cast aluminum.

- I also stick weld and have never done aluminum,but several years ago I bought aluminum welding rod from I think it was Northern Tool.It is a zinc based 1/8 bare rod you use with a propane torch.It worked for me and probably will for you.TIG would be overkill for that part.

- Q: Can aluminum sheets be used for insulation jackets?

- Yes, aluminum sheets can be used for insulation jackets. Aluminum has excellent thermal conductivity properties, which allows it to effectively reflect heat and prevent the transfer of thermal energy. This makes it an ideal material for insulation jackets, as it helps to maintain temperature control and minimize heat loss or gain. Additionally, aluminum sheets are lightweight, durable, and resistant to corrosion, making them a practical choice for insulation applications.

- Q: What are the different types of alloys used for powder-coated aluminum sheets?

- Powder-coated aluminum sheets utilize various alloys, each possessing distinct properties and characteristics. Among the commonly utilized alloys are: 1. The 3003 Alloy: This alloy finds extensive application in powder-coated aluminum sheets due to its exceptional corrosion resistance, formability, and high strength. Its versatility makes it suitable for building facades, signage, and automotive parts, where moderate strength and resistance to atmospheric corrosion are essential. 2. The 5052 Alloy: Renowned for its remarkable strength and excellent corrosion resistance, this alloy is commonly employed in marine and architectural applications that demand durability and resistance to saltwater and harsh environments. Additionally, it is frequently used for manufacturing electrical enclosures and transportation equipment. 3. The 6061 Alloy: This highly versatile alloy offers outstanding weldability, formability, and machinability. It finds application in various fields, including aerospace components, marine hardware, structural components, and automotive parts. Its corrosion resistance allows for easy powder coating, enhancing appearance and providing additional protection. 4. The 7075 Alloy: Noted for its exceptional strength-to-weight ratio and fatigue resistance, this alloy is predominantly utilized in aerospace applications, such as aircraft fittings and structural components, where strength and lightweight properties are crucial. Although its higher cost limits its use in powder-coated aluminum sheets, it remains present in specific specialized applications. These examples represent only a fraction of the diverse range of alloys employed in powder-coated aluminum sheets. The selection of an alloy depends on specific application requirements, encompassing factors such as strength, corrosion resistance, formability, and cost.

- Q: Calculate the mass in grams of Iodine (I2) that will react completely with 20.4 g of aluminum to form aluminum oxide (AlL3)

- Aluminium oxide? Shouldn't it be Aluminium iodide? 1. Form a balanced equation 3I2 + 4Al - 2Al2I3 2. Number of moles of Al 20.4/(Mr of Al) = 20.4/27 = 0.7555mol 3. Number of moles of I2 0.7555/4 x 3 = 0.5666mol 4. Mass of I2 required = 0.5666 x Mr of I2 = 0.5666 x (127x2) Ans: 143.9164g

- Q: What is the yield strength of aluminum sheets?

- The yield strength of aluminum sheets can vary depending on the specific grade and thickness of the sheet. However, on average, aluminum sheets have a yield strength ranging from 14,000 to 24,000 pounds per square inch (psi).

- Q: Can aluminum sheets be etched or engraved?

- Yes, aluminum sheets can be etched or engraved. Etching or engraving on aluminum sheets is a process that involves removing some of the material from the surface using acid or a high-powered laser. This can be done to create intricate designs, patterns, or even text on the aluminum sheet. The etching or engraving process can be used for various applications, such as signage, decorative pieces, or industrial parts. The resulting etched or engraved design on the aluminum sheet can be further enhanced by adding color or other finishes to create a desired look.

Send your message to us

Welding Aluminum Sheets - AA1XXX Coated Aluminum Coils for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords