Berkley Jensen Aluminum Foil 1000 Sq Ft - Mill Finished Aluminium Coils for Coca Cola Package

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

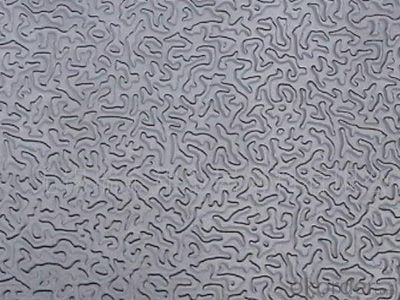

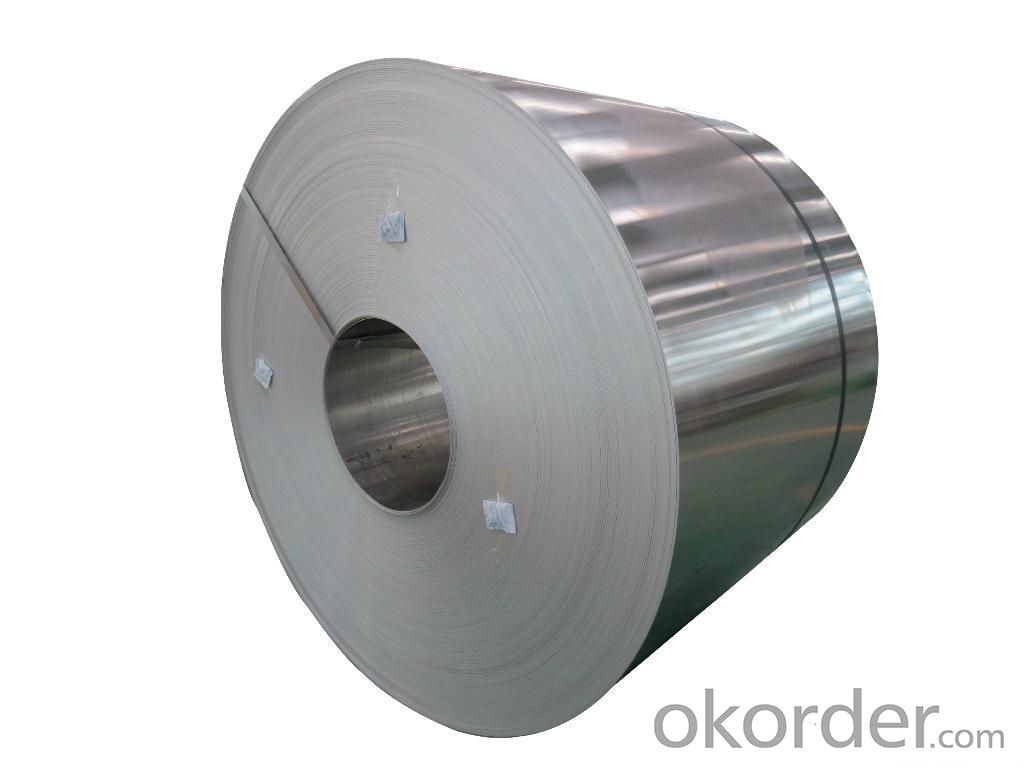

1.Structure of Mill Finished Aluminium Coils for Coca Cola Pakcage

Mill Finished Aluminium Coils for Coca Cola Pakcage is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Mill Finished Aluminium Coils for Coca Cola Pakcage

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image of Mill Finished Aluminium Coils for Coca Cola Pakcage

4. Product Specification of Mill Finished Aluminium Coils for Coca Cola Pakcage

| ALLOY | TEMPER | THICKNESS | WIDTH | DELIVERY TIME |

| AA3104 | H19 | 0.26MM | 300MM-500MM | 35 DAYS |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: I have a 24' round pool with aluminum deck all the way aroundThe previous owner used bungee cords (you know the ones with two hooks) and ropes to anchor the pool cover to the poolUnfortunately the cover deteriorated and we are opening the pool for the first time this year? I notice the aluminum deck overhangs the pool by a few inchesI see most of the covers they sell slip over the pool like a sockBut in this case there is no quot;lipquot; to slip the pool covers overMy question is what is the method to anchor the pool cover in this case (Proper way)Could I simply drill small holes and place steel eyelets around the aluminum deck post and use some sort of tensioning system to tension the cover in place?

- if you signed the purchase agreement then you should know the price it should have been on the purchase agreement.

- Q: well my family is comming up for a little get together this weekend and i was wondering if anyone had and good and not traditional brownie recipes to make to 'wow' the family.

- it might be that she is getting ready for solids, when my last ds was about her age he also would wake up like that, so when he was that age i started to wean him, and as soon as he did take it in he started to sleep through the night againand also make sure she doesn't sleep too much during the day, what i did is he would sleep in the afternoon, like from 11 am to 1 or 2 pm, and then he would sleep again around 4 pm to 5 or 6 pm, and then he wouldn't sleep anymore, and i put him in at 9 pm, and he would sleep through until 6 ambest of luck

- Q: I'm planning on making coq au vin tonight, and the recipe says to cook it in a dutch oven and then to put that in the oven, but I don't have a dutch oven, nor do I have the funds to buy one at the momentI was thinking of using a pot but I'm not too sure if they are oven proof and I don't want to risk it, so is it okay if I cook it in the pot and then transfer it to an oven proof dish and cover it with aluminium foil? Will it have the same effect? Please let me know, or if it's not okay what should I do? Thanks so much!

- You can use a pot or panMost lids will be able to take the heat of the oven, the handles or the pot or pan as wellYou will not have the oven high enough to melt most handles(unless your pans are VERY inexpensive) The handles and nobs on lids are not plastic but a composite that can withstand heat, some up to 400 degreesIf you are concerned though a double layer of aluminum foil sealed well around the edge of the pot or pan should workThe oven proof dish should work so long as it is not too largeThe idea is you want your chicken at least partially submerged in the cooking liquid and if you go from a pan to a 13X9 baking pan your chicken will be spread out over a larger area and some may not be covered with liquid.

- Q: The Linear attenuation coefficient, and how to find the Mass attenuation coefficient, knowing their Densities? I have been searching everywhere, in books, from the internetIt is unbelievable, there is not a single place that have the informationPlease help me to find itIf you have the source, please give me its webpage as wellThank you so much!!

- Yes there is something wrong, and you need to find a way to eat more veggiesExplore different ways they are cookedChetak

- Q: How does the aluminum foil stand suction bag fit into the liquid?

- With filling machine, automatic filling machine proofing, can be manually sealed with filling machinePlastic packing products with the same tripod

- Q: And if I really do need to remove that skin, is there a way other than charring them on a grill?I live in an apartment with and electric stove PThanks

- They taste better with skin removedThe skin remains a bit tough so once the skin is removed the pepper is nice and tenderA quick way to skin the peppers in an electric ovenHalf the pepper and rub the skin with a bit of oilPlace in hot oven and then turn broiler onBroil until skin begins to charTurn oven off and cover pan with aluminum foil or put all the pepper halves in a bowl and cover bowlLet the peppers steam for a bit and the skins will be fairly easy to removeDon't rinse the peppersYou want some of the char to stick to the peppersThere is a lot of flavor there.

- Q: It just has to be spun by a small DC motor, but what metal would be good for making a small propeller?

- Either copper or aluminum, when formed, copper will hold it's shape better and is easy to workAluminum is also pretty easy to work if you can get a soft grade, and yes, it does come in different grades If you have to form and fasten the individual blades to a hub, then copper is the best choice as it can be soldered easily.

- Q: A horizontal aluminum rod 4.8 cm in diameter projects 5.3 cm from a wallA 1200 kg object is suspended from the end of the rodThe shear modulus of aluminum is 3.0 x 10^10 N/m^2Neglecting the rod's mass, find:(A) The shear stress on the rod(B) The vertical deflection of the end of the rod.The answers are:(A) 6.5 x 10^6 N/m^2 (B) 1.1 x 10^(-5) mbut I don't know how to get these answers, please help me!

- If in need of tinkling Chinese ball See famous Dr Wun Hung Lo.

- Q: please, i need help!

- I once used a round piece of aluminum foil for a lake in a shadow box (diorama), got a good grade too! Depending on what color you want, you can also use blue or green glass (careful!) or one of those little round mirrors that you sometimes see in stores that display those little crystal figurines, (they sit the figurine on top of the little round mirror, like in Halmark stores), they even make those in blue occasionallyIf you want something a little thicker than aluminum foil, you could go to the grocery store and get one of the packages of disposable pie pans (they are thick aluminum and usually come in a package of like 3) for only a few bucks, and cut one of those up into the shape you wantYou can also just use anything small, flat, and roundish, and paint it up into whatever color you want, then put a coat of clear varnish or 'shellac' over it to make it shiny, or even stretch a piece of kitchen plastic wrap over it to give it a sheenGood luck, hey, let me know what you end up using (even if its not my idea!) Good luck!! :)

Send your message to us

Berkley Jensen Aluminum Foil 1000 Sq Ft - Mill Finished Aluminium Coils for Coca Cola Package

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords