Coil Coated Aluminum Plate - Mill Finish Aluminum Coil in Rolls 1000 Series

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Mill Finish Aluminum Coil in Rolls 1000 Serie

Alloy: 1050, 1060, 1100, 3003, 3004, 3005, 3105, 5005, 5052, 5083, 5754

2) Temper: Various status

3) Thickness: 0.3-150mm

4) Width: 300-1950mm

5) Length: Under9500mm/ Coil

6) Weight: 2.5-5.0 tons per coil

7) Dimensions and weight can be produced according to clients' specifications.

8) Inner Diameter: 505mm, 605mm

9) Packing: Export standard, wooden pallet.

10) Delivery time: 20 days

11) Minimum order quantity: 5 tons per size.

12) The term of payment: T/T, irrevocable L/C at sight.

13) Surface: Bright

14)Origin: China

2. Application of Mill Finish Aluminum Coil in Rolls 1000 Serie

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Mill Finish Aluminum Coil in Rolls 1000 Serie

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

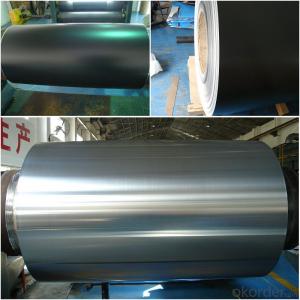

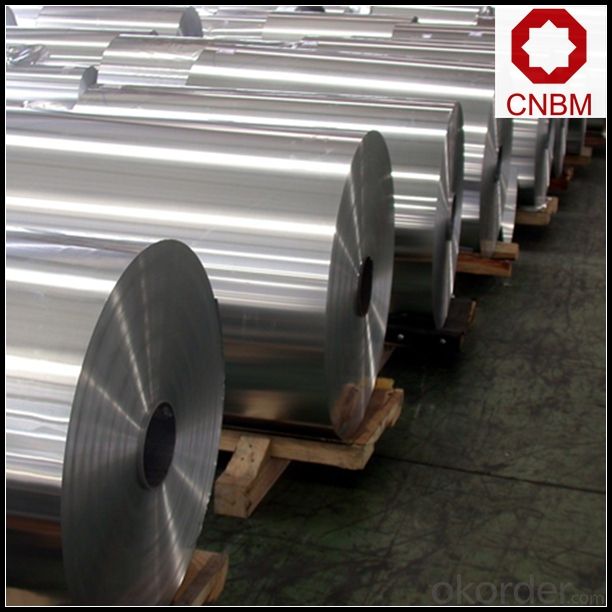

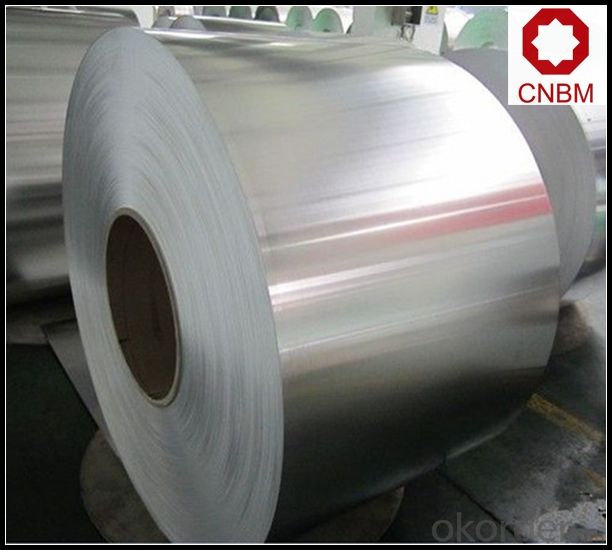

5. Image of Mill Finish Aluminum Coil in Rolls 1000 Serie

6. Package and shipping of Mill Finish Aluminum Coil in Rolls 1000 Serie

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Are aluminum coils easy to bend and shape?

- Aluminum coils, being a malleable metal, can be easily bent and shaped. This characteristic makes them ideal for various shaping and forming tasks. Different techniques like rolling, bending, or pressing can be employed to manipulate aluminum coils, making them applicable in industries such as construction, automotive, and manufacturing. However, the ease of bending and shaping may vary depending on the specific alloy and thickness of the coil. Thicker coils may necessitate more force and specialized equipment, and different alloys may exhibit varying levels of malleability. In conclusion, aluminum coils present a versatile and relatively uncomplicated material for bending and shaping purposes.

- Q: I have a school project due in a couple weeks and I need to make a life size sculpture of a camera. I don't want to make it solid because that would use a lot of clay and wouldn't evenly cook. Can I put something inside like aluminum foil?

- What kind of clay and what kind of cooking?

- Q: Is it possible to utilize aluminum coils for the storage of food items?

- <p>Yes, aluminum coils can be used to store foodstuffs, particularly in the form of aluminum foil. Aluminum foil is a common food storage material due to its properties such as being lightweight, flexible, and providing a barrier against air and moisture. It is often used for wrapping food for cooking, freezing, or preserving. However, it's important to ensure that the aluminum does not react with the food, especially acidic foods, as this could lead to contamination. Additionally, it's not recommended for long-term storage as it does not provide a complete seal or barrier against all contaminants.</p>

- Q: How are aluminum coils used in the production of HVAC ductwork?

- Aluminum coils play a significant role in the production of HVAC ductwork. These coils are made from high-quality aluminum material that is lightweight, durable, and corrosion-resistant, making them ideal for use in HVAC systems. The first step in utilizing aluminum coils for HVAC ductwork production is the manufacturing process. The coils are initially rolled into thin sheets, which are then cut into specific widths and lengths to match the size requirements of the ductwork. This flexibility in sizing allows for customized ductwork that fits perfectly in various HVAC systems. Once the aluminum coils are cut into the desired dimensions, they are then formed into the shape of the ductwork. This can be done through a variety of methods, such as bending, folding, or rolling, depending on the design and specifications of the ductwork. One of the key advantages of using aluminum coils in HVAC ductwork production is their excellent thermal conductivity. Aluminum is a highly effective heat conductor, which means that it can efficiently transfer heat or cold air throughout the HVAC system. This property is essential for the proper functioning of the ductwork, as it helps maintain the desired temperature in different areas of a building. Moreover, aluminum coils are known for their resistance to corrosion, which is crucial in HVAC systems. The coils are exposed to various elements, including moisture, which can lead to rust and deterioration in other materials. Aluminum, on the other hand, naturally forms a protective oxide layer that prevents corrosion, ensuring the longevity and reliability of the HVAC ductwork. Furthermore, the lightweight nature of aluminum coils makes them easy to handle and install. This reduces the labor and time required for ductwork installation, resulting in cost savings for both manufacturers and installation teams. Additionally, the lightweight nature of aluminum coils reduces the overall weight of the HVAC system, making it more energy-efficient and reducing the strain on other components. In conclusion, aluminum coils are an essential component in the production of HVAC ductwork. Their lightweight, durable, and corrosion-resistant properties, along with excellent thermal conductivity, make them ideal for efficiently transferring air throughout the HVAC system. Additionally, the flexibility in sizing and ease of installation further contribute to their widespread use in the HVAC industry.

- Q: What are the different surface treatment options available for aluminum coils?

- There are several surface treatment options available for aluminum coils, each serving different purposes and providing unique benefits. Some of the commonly used surface treatment options include: 1. Anodizing: Anodizing is an electrochemical process that creates a protective oxide layer on the surface of the aluminum coil. This treatment enhances corrosion resistance, improves durability, and allows for coloring options. 2. Painting: Painting the aluminum coil provides an aesthetic finish while also protecting it from corrosion. The coil can be coated with various types of paints, such as polyester, epoxy, or polyurethane, depending on the desired appearance and level of protection required. 3. Powder Coating: Powder coating involves applying a dry powder to the aluminum coil's surface and then curing it with heat. This process creates a durable and attractive finish that is resistant to chipping, scratching, and fading. Powder coating also offers a wide range of color options and can be used in various applications. 4. Brushing: Brushing the aluminum coil creates a brushed or satin finish with visible linear patterns. This treatment is commonly used for decorative purposes, giving the coil a unique and visually appealing appearance. 5. Laminating: Laminating involves bonding a protective layer, such as a PVC film or a polyester film, onto the surface of the aluminum coil. This treatment provides additional protection against scratches, abrasion, and UV radiation while also offering customization options. 6. Chemical Conversion Coating: Chemical conversion coating, also known as chromate conversion coating, involves applying a thin layer of chromate onto the aluminum coil's surface. This treatment enhances corrosion resistance, improves paint adhesion, and provides a base for subsequent painting or powder coating. It is important to choose the appropriate surface treatment option based on the specific requirements of the application, such as durability, corrosion resistance, aesthetics, and cost-effectiveness. Consulting with experts in the field can help determine the most suitable treatment option for aluminum coils.

- Q: How do aluminum coils withstand extreme weather conditions?

- Due to the unique properties of aluminum, aluminum coils can endure harsh weather conditions. Firstly, aluminum's lightweight nature allows it to remain flexible and resistant to bending or warping when faced with strong winds or heavy snow loads. As a result, aluminum coils are less likely to be damaged during extreme weather events like hurricanes or blizzards. Moreover, aluminum possesses a high resistance to corrosion. When exposed to air, it forms a protective oxide layer on its surface, preventing rusting or deterioration caused by moisture or severe weather conditions. This protective layer acts as a barrier against elements such as rain, snow, or saltwater, making aluminum coils highly durable and long-lasting. Additionally, aluminum exhibits high thermal conductivity, enabling it to efficiently dissipate heat. This property ensures that aluminum coils effectively transfer heat away from the system, preventing overheating and potential damage during hot weather conditions. Furthermore, the efficient dissipation of heat contributes to the energy efficiency of aluminum coils. Lastly, aluminum is a non-magnetic material, rendering it unaffected by electromagnetic interference or lightning strikes. This quality makes aluminum coils safe and dependable in areas prone to electrical storms or high levels of electromagnetic activity. To summarize, aluminum coils are designed to endure extreme weather conditions due to their lightweight, corrosion-resistant, thermally conductive, and non-magnetic properties. These characteristics make aluminum coils highly durable, dependable, and suitable for various applications, including HVAC systems, automotive cooling, and electrical wiring.

- Q: What are the different pre-treatment methods for aluminum coils?

- Some of the different pre-treatment methods for aluminum coils include cleaning, degreasing, etching, and phosphating. Cleaning removes dirt, dust, and other impurities from the surface of the coil. Degreasing eliminates oils and greases that may be present. Etching creates a rough surface on the aluminum, which helps in improving adhesion for subsequent coatings. Phosphating involves applying a phosphate coating to enhance corrosion resistance and improve paint adhesion. These pre-treatment methods ensure that the aluminum coils are properly prepared before any further processing or coating.

- Q: Are aluminum coils resistant to chemical exposure?

- Aluminum coils are generally known to be highly resistant to chemical exposure. Aluminum itself has excellent corrosion resistance properties, making it suitable for various applications where it may come into contact with chemicals. The oxide layer that naturally forms on the surface of aluminum coils acts as a protective barrier, preventing further corrosion and degradation when exposed to many chemicals. However, it is essential to note that the resistance of aluminum coils to chemical exposure may vary depending on the specific type and concentration of the chemical involved. Some aggressive chemicals or strong acids may still cause damage or corrosion over time. Therefore, it is always advisable to consult with experts or refer to specific chemical compatibility charts to determine the compatibility of aluminum coils with particular chemicals or environments.

- Q: Can aluminum coils be used in food packaging?

- Yes, aluminum coils can be used in food packaging. Aluminum is a safe and versatile material that has been widely used in the food packaging industry for many years. It offers various benefits such as being lightweight, resistant to corrosion, and having excellent thermal conductivity. These properties make it ideal for food packaging applications where it is important to preserve the quality, freshness, and safety of the food products. Aluminum coils can be easily formed into different shapes and sizes, allowing for customized packaging solutions. Additionally, aluminum is a sustainable material as it is 100% recyclable, which further enhances its appeal for food packaging.

- Q: Can aluminum coils be used in the production of aluminum downspouts?

- Certainly, aluminum coils have the potential to be employed in the manufacturing process of aluminum downspouts. Normally, high-grade aluminum alloy is utilized to fabricate aluminum coils, which are subsequently transformed into thin sheets by means of rolling. These sheets can be conveniently cut and molded into diverse dimensions and forms, including downspouts. The lightweight, long-lasting, and corrosion-resistant characteristics of aluminum make it a favored option for downspouts. Moreover, aluminum coils can be effortlessly manipulated and shaped according to precise design prerequisites, rendering them appropriate for the production of aluminum downspouts.

Send your message to us

Coil Coated Aluminum Plate - Mill Finish Aluminum Coil in Rolls 1000 Series

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords