Custom Aluminum Coil for High Quality Food Package Aluminum Foil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 3800 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum

1) Alloy | 1050,1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

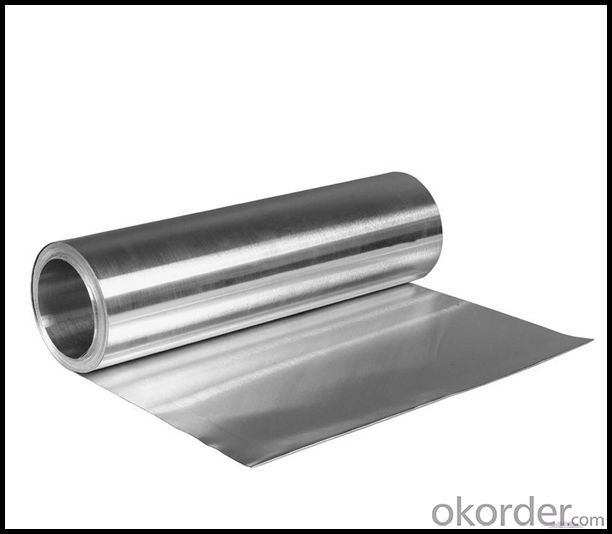

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7. FAQ

Q: What is the produce prase? |

A: Normally it would be 40days after received your deposit. |

Q: Can you provide free samples? |

A: Yes, free samples will be sent to you on freight at destination. |

Q: Can I get your latest catalogue? |

A: Yes, it will be sent to you in no time. |

Q: What is the MOQ? |

A: 3 tons |

Q: What are your payment terms? |

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q: What are environmentally friendly types of aluminum coil and do they exist?

- <p>Yes, there are environmentally friendly types of aluminum coil. These include recycled aluminum coils, which are made from aluminum that has been reprocessed and reused, reducing the need for new aluminum production and its associated environmental impact. Additionally, aluminum coils with a high recycled content are considered eco-friendly as they contribute to waste reduction and energy conservation. The production of recycled aluminum uses significantly less energy compared to virgin aluminum, making it a more sustainable choice.</p>

- Q: aluminum foil production of ERP software, requiring a comprehensive production process, and have special assistance to pre operation, the best price is reasonable

- Baidu, Inc., a China military there, here not to send.

- Q: Can the color coated aluminum roll be bent easily and won't break?

- As an ornamental material, it has the incomparable advantages of the following products. It can be guaranteed to be durable at least for 30 years after being treated with special surface. It is durable and has super weatherability. Fluorocarbon coating aluminum coil is made of fluorine enyne fluorocarbon resin as basic monomer, acid and alkali corrosion resistance, friction resistance and its decay, compared with plastic coating, molecular structure, sun room, bright and smooth: product classification, UV absorbers can be divided according to the gloss matte and high gloss series.

- Q: Why the aluminum sheet crack after?

- What I want to add is to choose such welding wires as 5383 or 5183 wire whose magnesium content is higher than 5754 wire. The loss of magnesium due to high temperature in welding process may reduce the intensity of welding area.

- Q: Are aluminum coils more cost-effective compared to other materials like copper?

- Aluminum coils are generally more cost-effective than other materials like copper for several reasons. To begin with, aluminum is a more abundant metal, making it cheaper to produce. Its abundance also results in more stable prices, reducing the likelihood of market fluctuations and further enhancing its cost-effectiveness. Furthermore, aluminum coils have a lower density compared to copper coils, resulting in lighter units. This lighter weight not only reduces costs for transportation and installation but also makes them easier to handle and maneuver during the manufacturing process. In addition, aluminum coils possess excellent thermal conductivity properties, enabling efficient heat transfer. This leads to more efficient cooling or heating systems, resulting in lower energy consumption and operating costs in the long run. Moreover, aluminum exhibits higher resistance to corrosion compared to copper, making it more durable and requiring less maintenance. The longer lifespan of aluminum coils reduces the need for replacements and repairs, further contributing to their cost-effectiveness. Lastly, aluminum coils are recyclable, and the recycling process requires significantly less energy than producing new aluminum. This aspect adds to the overall sustainability and cost-effectiveness of aluminum coils. In conclusion, considering their lower production costs, lighter weight, superior thermal conductivity, increased durability, and recyclability, aluminum coils are indeed a more cost-effective option compared to materials like copper.

- Q: How are aluminum coils inspected for defects?

- Aluminum coils are inspected for defects through various methods such as visual inspection, ultrasonic testing, eddy current testing, and X-ray inspection. These techniques help identify surface imperfections, cracks, porosity, and other defects that may affect the quality and integrity of the coils.

- Q: What is the structure of Aluminium Chloride at 180, 192.4 (melting point) and 200 degrees celsius? When does it exist as an ionic lattice and when as a Al2Cl6 dimer?

- Aluminium chloride sublimes (turns straight from a solid to a gas) at about 180°C. If it simply contained ions it would have a very high melting and boiling point because of the strong attractions between the positive and negative ions. The implication is that it when it sublimes at this relatively low temperature, it must be covalent. The dots-and-crosses diagram shows only the outer electrons. Hope that help Check here for more information; www.chemguide .uk/atoms/bonding...

- Q: wikipedia says welding aluminum by means of stick welding is possible but i have always been told TIG is the only way to weld aluminum. what do i need in order to stick weld aluminum? BTW i have a Lincoln Electric AC 225 Stick Welder

- Stick Welding Aluminum

- Q: Are aluminum coils suitable for high-temperature roofing applications?

- No, aluminum coils are not suitable for high-temperature roofing applications.

- Q: Is it possible to use a welding process to join two pieces of aluminum coil?

- <p>Yes, you can weld two pieces of aluminum coil together, but it requires specific techniques and equipment. Aluminum welding is different from steel welding and requires a TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) welding process. It's crucial to use a clean, dry aluminum filler rod and maintain a clean, oxide-free surface on the aluminum. Additionally, a shielding gas like argon is necessary to protect the weld area from oxidation. Special precautions must be taken due to aluminum's high thermal conductivity and reactivity, so it's recommended to have experience or professional guidance when welding aluminum.</p>

Send your message to us

Custom Aluminum Coil for High Quality Food Package Aluminum Foil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 3800 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords