Mill Finish Aluminum Sheet for Building Curtain Wall with Bitumen Sheets Aluminum Backing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Mill Finish Aluminum Sheet for Building Curtain Wall

ALLOY | AA1050 AA1060 AA1070 AA1100 ETC AA3003 AA3004 AA3005 AA3104 AA3105 ETC AA5005 AA5052 AA5083 AA5754 ETC AA8011 AA8006 AA8079 ETC |

TEMPER | H14,H16,H18,H22,H24,H26,H32,O/F |

THICKNESS | ≥0.2MM |

WIDTH | 30mm-2100mm |

COIL WGT | 2Mt - 3Mt |

COIL ID | φ508mm,φ610mm |

SURFACE | PE Protecting film |

STANDARD | GB/T 3880-2006 |

2. Application of Mill Finish Aluminum Sheet for Building Curtain Wall

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Mill Finish Aluminum Sheet for Building Curtain Wall

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

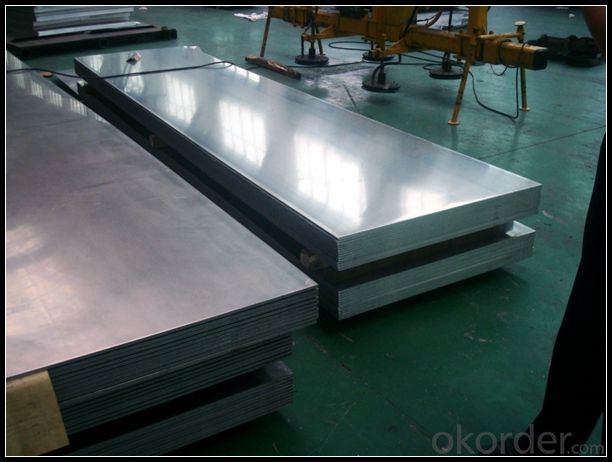

5. Image of Mill Finish Aluminum Sheet for Building Curtain Wall

6. Package and shipping of Mill Finish Aluminum Sheet for Building Curtain Wall

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: This question asks for an overview of the various types of coatings applied to aluminum profiles used in exterior cladding systems.

- <p>Aluminum profiles for exterior cladding are often coated to enhance their durability, weather resistance, and aesthetic appeal. Common types of coatings include: 1. Anodizing, which creates a protective oxide layer on the aluminum surface. 2. Powder coating, a popular method that provides a durable and colorful finish. 3. Fluorocarbon coating, known for its excellent weathering and UV resistance. 4. PVDF (Polyvinylidene Fluoride) coating, highly resistant to chemicals and suitable for marine environments. 5. Electrophoretic coating, which offers a smooth, even finish. 6. Hot-dip galvanizing, a process that coats aluminum with a protective layer of zinc. Each coating type has specific advantages and is chosen based on the performance requirements and environmental conditions of the project.</p>

- Q: I am doing a project on Aluminum it has 13 protons just to make sure everyones on the same page. How much of it is left or exsits? Also how does it behave?

- As Vincent noted, aluminium is an abundant element in the earth's crust. It occurs in all clay minerals. Its main ore, bauxite(a mixture of aluminium hydroxides) is still available in vast deposits; particularly in Australia and South America. Aluminium is a reactive element, and so is not found in nature in the elemental form. Aluminium is a metal, and an amphoteric substance; that is; it reacts with both acids and bases.

- Q: Could induction heating fuenace be packaged with aluminum foil as insulation material?

- It’s useless. Aluminum foil will generate eddy and emit heat after medium induction, which will reduce the thermal efficiency of medium frequency. Now I provide a method for reference only. Induction coil will be water cooling and is packaged by thermal cement and other materials. Use asbestos sheet and other materials to transform the both ends of induction heating coil as baffle which is mobile and convenient for load and unload. When steel tube is heated in the induction coil, you can put down the baffle to prevent large loss of heat, shorten heat time and improve heat efficiency. When the seamless steel tube is heated into setting temperature, you can open the baffle to conduct expanding process, and you don’t need to think about the thermorytic problem of steel tube in the expanding process. It’s important to shorten the time of expanding process. Baffle is used for heat retaining of medium frequency heating and extrusion forming in our factory. The method above for reference only.

- Q: How are aluminum sheets different from aluminum plates?

- Aluminum sheets and aluminum plates differ in terms of thickness. Sheets are typically thinner, usually less than 6 mm, while plates are thicker, typically more than 6 mm. Additionally, sheets are often used for lightweight applications such as packaging, whereas plates are commonly utilized for structural purposes or heavy-duty applications.

- Q: Does anyone know why Mercury -(Thimerosal) is used in Flu Vaccinations and where Mercuryisnot used Aluminium in other vaccines ? While these are known to be toxic metals, can these cause headaches, severe hot burning heads and or Sinusitus ?

- Thimerosal is not the same as mercury. It's a mercury-based preservative which to prevent the growth of germs, bacteria and fungi, that can contaminate them. It's used in seasonal flu vaccine because the vaccine is produced in large quantities and often in multi-dose vials. Thimerosal helps safeguard against possible contamination of the vial once it is opened. The aluminum in vaccines is aluminum hydroxide, aluminum phosphate, alum (potassium aluminum sulfate), or mixed aluminum salts. They're an adjuvant added to enhance the immune response in the vaccinated individual. Whether or not something is toxic has to do with how much a person receives not the substance itself. People can die from drinking too much water, but we don't go around calling water toxic. The amount of mercury or aluminum in vaccines is so small that it's not toxic. You ingest more mercury by eating fish and a baby ingest more aluminum in breast milk than they get in a vaccine. So if mercury and aluminum caused head aches, severe hot burning heads or sinusitis in a person, that person would have a lot more to worry about than vaccines since they would be exposed to those things in so many other ways.

- Q: What are the specific rules or benchmarks that must be followed when utilizing aluminum sheets for construction purposes?

- <p>Yes, there are special regulations and standards for using aluminum sheets in construction projects. These include material specifications, thickness, and strength requirements as per the American Society for Testing and Materials (ASTM) standards, such as ASTM B209 for aluminum sheet and plate. Additionally, the International Building Code (IBC) and local building codes provide guidelines for the use of aluminum in construction. These standards cover aspects like fire resistance, structural integrity, and weather resistance. Compliance with these regulations ensures safety, durability, and compliance with construction laws.</p>

- Q: How does the surface roughness of aluminum sheet affect its performance?

- The overall performance of an aluminum sheet can be greatly influenced by its surface roughness. The roughness of the sheet's surface refers to the presence of irregularities, bumps, and texture. Various methods, such as Ra or Rz, can be used to measure these irregularities. One important effect of surface roughness on aluminum sheet performance lies in its ability to bond with other materials. A smoother surface allows for better adhesion, whether through welding, gluing, or painting. In contrast, a rough surface reduces the contact area and weakens the bond. This is particularly crucial in applications where the aluminum sheet is used structurally or in manufacturing processes that require strong adhesion. Surface roughness also affects the sheet's light reflection capabilities. A smoother surface reflects light more uniformly, resulting in a higher level of reflectivity. On the other hand, a rough surface scatters light in different directions, decreasing overall reflectivity. This property is relevant in applications like architectural cladding, where the desired aesthetic appearance depends on consistent light reflection. Additionally, the surface roughness of aluminum sheets can impact their resistance to corrosion. A smoother surface is less susceptible to corrosion as it provides fewer sites for corrosion to start. Conversely, a rougher surface may contain micro crevices or grooves that can trap moisture, salts, or other corrosive substances, speeding up the corrosion process. Maintaining a smooth surface is crucial in applications where corrosion resistance is vital, such as marine environments or outdoor structures. Lastly, surface roughness affects the mechanical properties of the sheet. A rough surface can concentrate stress, making the sheet more prone to fatigue, cracks, or other mechanical failures. Smoother surfaces distribute stress more evenly, enhancing the sheet's overall strength and resistance to deformation. In conclusion, the surface roughness of an aluminum sheet is of utmost importance in determining its performance. It affects adhesion, reflectivity, corrosion resistance, and mechanical properties. Therefore, it is essential to consider and control surface roughness in various applications to ensure optimal performance and longevity of aluminum sheets.

- Q: Can aluminum sheets be used for architectural sunshades?

- Yes, aluminum sheets can be used for architectural sunshades. Aluminum is a lightweight and durable material that is commonly used in construction and architecture. It can be easily shaped and manipulated to create various designs and configurations for sunshades, providing protection from sunlight and enhancing the aesthetic appeal of buildings. Additionally, aluminum is resistant to corrosion, making it suitable for outdoor applications and ensuring the longevity of sunshade structures.

- Q: Heating aluminum plate, heating scheme, urgent ~!

- For aluminum heating silicon heating plate is a good choice. The four corners can be fixed by screws, Beijiao can. Installation is very convenient. I was in the goodway procurement. They are guaranteed for one year.

- Q: Is it possible to utilize aluminum sheets for the construction of outdoor advertising billboards?

- <p>Yes, aluminum sheets are commonly used for outdoor advertising billboards due to their durability, lightweight, and resistance to weather conditions. They are easy to install, maintain, and can be printed with high-quality graphics. Additionally, aluminum's corrosion resistance makes it a sustainable choice for long-term outdoor use.</p>

Send your message to us

Mill Finish Aluminum Sheet for Building Curtain Wall with Bitumen Sheets Aluminum Backing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords