Mill Finish Aluminum Coil for Subwoofer Color Coating

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Mill Finish Aluminium Coil for Color Coating

Material | Alloy Aluminum 1XXX,3XXX,5XXX or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating,PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

2. Application of Mill Finish Aluminium Coil for Color Coating

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Mill Finish Aluminium Coil for Color Coating

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

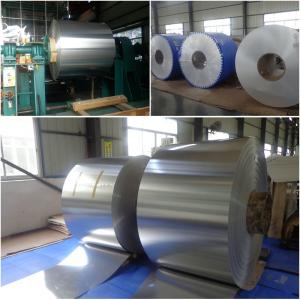

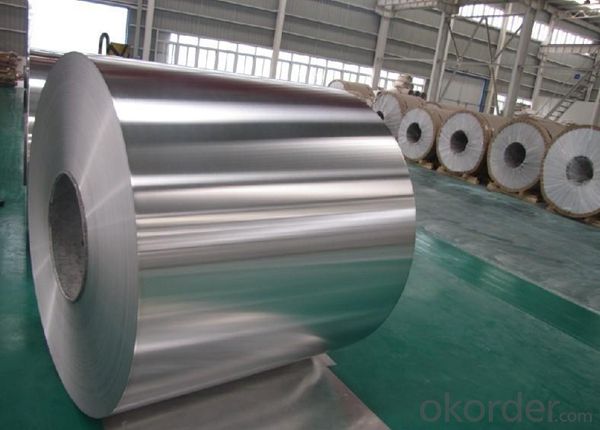

5. Image of Mill Finish Aluminium Coil for Color Coating

6. Package and shipping of Mill Finish Aluminium Coil for Color Coating

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Why is the aluminum roll upset?

- Mainly in the aluminum slitting process, for various reasons, does not meet the standards and specifications of products, can be used to roll the machine from the new trimming and slitting, winding up to meet customer needs of product specifications

- Q: This question asks for a comparison between aluminum coil and iron coil, highlighting their distinct properties and uses.

- <p>Aluminum coil and iron coil differ in several aspects. Aluminum coil is lightweight, corrosion-resistant, and has excellent electrical and thermal conductivity, making it ideal for electrical wiring, heat sinks, and food packaging. Iron coil, on the other hand, is heavier, stronger, and more durable, commonly used in construction, automotive, and heavy machinery due to its high tensile strength. Iron also has magnetic properties, useful in applications like transformers and electromagnets. While aluminum is non-magnetic, it is more cost-effective and has better recyclability compared to iron.</p>

- Q: This question asks whether aluminum coils are produced using recycled materials.

- <p>Yes, aluminum coils can be made from recycled materials. Recycling aluminum is a common practice because it conserves resources and energy. Recycled aluminum, also known as secondary aluminum, is processed from various waste materials such as used beverage cans, automotive parts, and construction materials. The recycling process involves melting the scrap aluminum, which requires significantly less energy compared to producing aluminum from raw materials. This makes the production of aluminum coils from recycled materials more sustainable and environmentally friendly.</p>

- Q: How are aluminum coils used in the production of industrial machinery?

- Aluminum coils are commonly used in the production of industrial machinery for various purposes. These coils are primarily utilized in the fabrication of heat exchangers, such as condensers and evaporators, due to aluminum's excellent thermal conductivity. Additionally, aluminum coils are used to manufacture air conditioning systems, refrigeration units, and cooling towers, as they offer lightweight and corrosion-resistant properties. They are also employed in the construction of electrical transformers and motors due to their high electrical conductivity. Overall, aluminum coils play a crucial role in the manufacturing of industrial machinery, contributing to enhanced efficiency, durability, and performance.

- Q: What is the typical warranty period for aluminum coils?

- The warranty period for aluminum coils can differ based on the manufacturer and the specific product. Typically, aluminum coils have warranty periods between 5 and 10 years. This means that the manufacturer will take responsibility for any defects or problems that may occur with the aluminum coils during this time. It is worth mentioning that certain manufacturers may offer extended warranty choices for an extra fee. Moreover, it is recommended to review the warranty terms and conditions provided by the manufacturer as they might have specific prerequisites or restrictions for the warranty to remain valid.

- Q: Can aluminum coils be used in the production of architectural façades?

- Yes, aluminum coils can be used in the production of architectural façades. Aluminum is a popular choice for façades due to its lightweight nature, durability, and versatility. Aluminum coils can be easily formed and shaped to create various architectural designs, making them suitable for use in the construction of façades.

- Q: Briefly describe the process of aluminum production from bauxite. Describe the electrolyte and write the anode and cathode half-reactions.

- Bauxite is dissolved in NaOH to remove impurities and form aluminum hydroxide; the aluminum hydroxide is then precipitated out, and water is removed to produce pure aluminum oxide (alumina). In aluminum production, alumina (Al2O3) is dissolved in molten cryolite (Na3AlF6). This molten mixture is then placed in a container with graphite electrodes (cathode and anode are both graphite). The molten mixture serves as the electrolyte. At the cathode: Al3+ (l) + 3e- ---- Al (l) Aluminum ions gather electrons to form aluminum metal, which is liquid due to the high temperatures. The molten metal sinks to the bottom of the container, and is piped off. At the anode: 2O2- (l) --- O2 (g) + 4e- The oxide ions from alumina lose their electrons to form oxygen gas.

- Q: Are there any recycling programs for used aluminum coils?

- Yes, there are recycling programs available for used aluminum coils. Many recycling centers and scrap yards accept aluminum coils for recycling, as aluminum is a highly recyclable material.

- Q: I was going to buy a turkey roaster pan today and an elderly couple stopped me and told me to buy another one that was made of stainless steel instead of aluminum because aluminum does something to your brain. What is the story?Just curious. Does this also ring true for using a sheet of aluminum foil over baking sheets while cooking cookies or fries or something? I always coat my cookie sheets with foil. Just curious...

- No, the carburetor doesn't get that hot (you wouldn't want it to run hot because it carries gasoline and could ignite or explode unexpectedly) - besides, most cars today do not have a carburetor (they use a fuel injection system). They were probably referring to the exhaust manifold which is the hottest part on the engine - and certainly hot enough to cook food. You would have to figure out how to secure the food in a container to maintain contact with the manifold.

- Q: Are aluminum coils suitable for insulation purposes?

- Yes, aluminum coils are suitable for insulation purposes. Aluminum is a highly effective conductor of heat and electricity, making it an ideal choice for insulation. Aluminum coils can be used in various applications such as HVAC systems, refrigeration units, and electrical wiring. The coils are typically coated with a layer of insulation material such as polyurethane foam or fiberglass to enhance their insulating properties. The combination of aluminum and insulation helps to prevent the transfer of heat or cold, providing excellent thermal insulation. Additionally, aluminum is lightweight, durable, and resistant to corrosion, making it a reliable choice for long-term insulation needs.

Send your message to us

Mill Finish Aluminum Coil for Subwoofer Color Coating

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords