Mild Q195/215 CNBM Steel Billets Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Product Description

| GRADE | SIZE | APPLICATION |

Q195/ Q215 | 100mm*100mm*6m | STEEL STRIP/STRUCTURE STEEL |

| 120mm*120mm*6m | ||

| 130mm*130mm*6m/12m | ||

| 150mm*150mm*6m/12m |

Chemical Compositon

Q195/ 215 | C (%) | Si (%) | Mn (%) | P(%) | S(%) |

| 0.06-0.12 | 0.15-0.30 | 0.35-0.50 | 0.045% Max | 0.045Max |

Company Information:

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

Packing & Delivery

1. Packaging: seaworthy package or as required

2. Delivery: 35-45 days or based on quantity

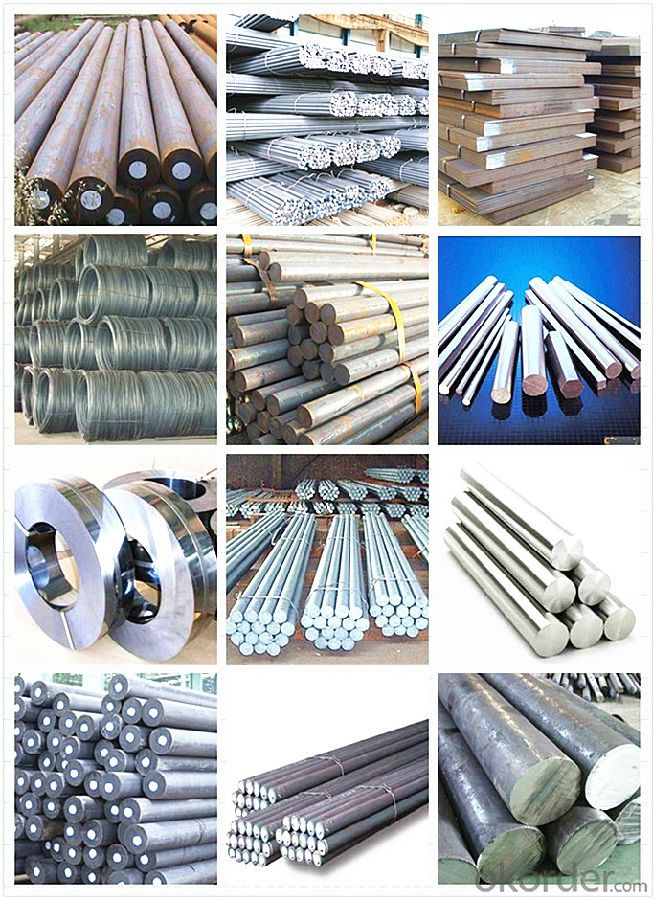

Products Show

Workshop

FAQ:

1.Your advantages?

Professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent

customer solution proposale

2. Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3. Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department

of these factories. Also CNBM is the holding company of many factories.

4. Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5. Trading Terms?

EXW, FOB, CIF, FFR, CNF

6. After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business

partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q:What are the main factors affecting the creep resistance of special steel?

- The main factors affecting the creep resistance of special steel are composition, microstructure, and processing conditions. Composition plays a critical role in determining the creep resistance of special steel. The presence of alloying elements such as chromium, molybdenum, and vanadium can enhance the creep resistance by forming stable precipitates or carbides that impede dislocation movement. These alloying elements also contribute to the formation of a protective oxide layer, which can further improve the resistance to creep. Microstructure is another important factor affecting creep resistance. Fine-grained structures, achieved through proper heat treatment or alloying, can hinder dislocation movement and enhance the strength of the material, thereby improving creep resistance. Additionally, the presence of grain boundaries can act as barriers to dislocation motion, reducing the creep rate. Processing conditions, including heat treatment and deformation processes, can significantly influence the creep resistance of special steel. The choice of heat treatment parameters, such as temperature and cooling rate, can affect the precipitation of strengthening phases and the formation of a desirable microstructure. Proper deformation processing, such as hot working or cold working, can refine the grain structure and enhance the creep resistance. Other factors that can affect the creep resistance of special steel include temperature, stress, and time. Higher temperatures can accelerate creep deformation, while higher applied stresses can increase the creep rate. The duration of exposure to elevated temperatures and stresses also plays a role, as prolonged exposure can lead to creep failure. In conclusion, the creep resistance of special steel is influenced by various factors, including composition, microstructure, processing conditions, temperature, stress, and time. By carefully considering and optimizing these factors, the creep resistance of special steel can be enhanced, making it suitable for high-temperature and long-term applications.

- Q:How is corrosion-resistant steel used in marine environments?

- Corrosion-resistant steel is commonly used in marine environments due to its ability to withstand the harsh conditions of saltwater and prevent corrosion. It is utilized in the construction of ships, offshore platforms, and various marine structures. The steel's high resistance to corrosion prolongs the lifespan of these structures, ensuring their durability and safety in challenging marine environments.

- Q:How does special steel perform in mining applications?

- Special steel performs exceptionally well in mining applications due to its unique properties and characteristics. It offers superior strength, hardness, and durability, making it highly resistant to wear, abrasion, and impact. This enables special steel to withstand the harsh and demanding conditions typically encountered in mining operations, including heavy loads, extreme temperatures, and corrosive environments. Additionally, its excellent machinability and weldability facilitate easy fabrication and repair of mining equipment, ensuring prolonged service life and efficient performance. Overall, special steel plays a crucial role in enhancing the productivity, safety, and reliability of mining operations.

- Q:How does special steel contribute to the manufacturing of surgical instruments?

- Special steel, which is also known as stainless steel, plays a vital role in the production of surgical instruments. Its exceptional properties make it an ideal material for manufacturing high-quality surgical instruments used in various medical procedures. To begin with, special steel exhibits a high resistance to corrosion and rust. Surgical instruments are constantly exposed to bodily fluids, sterilization processes, and harsh cleaning agents. The corrosion resistance of special steel guarantees the durability of these instruments, enabling them to withstand repeated use and cleaning without compromising their integrity. Furthermore, special steel possesses excellent strength and hardness characteristics. Surgical instruments must be robust and capable of withstanding the forces and pressures exerted during surgeries. The high strength and hardness of special steel ensure that these instruments retain their shape and sharpness even after multiple uses, minimizing the risk of breakage or deformation during critical procedures. Moreover, special steel is biocompatible, meaning it does not elicit reactions or complications when in contact with bodily tissues or fluids. This is particularly important for surgical instruments that come into direct contact with patients' bodies. The biocompatibility of special steel guarantees that there are no adverse reactions or complications when these instruments are used in surgeries, thereby reducing the risk of infections or other complications. In addition, special steel is highly machinable and can be easily molded into intricate shapes and designs. Surgical instruments require precision and accuracy to effectively fulfill their intended functions. The machinability of special steel allows manufacturers to create complex instruments with fine details and features, ensuring their optimal performance during surgical procedures. Furthermore, special steel can be efficiently sterilized. Sterilization is a critical step in ensuring the safety and effectiveness of surgical instruments. Special steel's ability to withstand high temperatures and various sterilization methods, such as autoclaving or ethylene oxide gas sterilization, makes it an ideal choice of material for surgical instruments. In conclusion, special steel significantly contributes to the manufacturing of surgical instruments due to its corrosion resistance, strength, biocompatibility, machinability, and sterilization capabilities. These properties guarantee that surgical instruments made from special steel are durable, reliable, safe, and effective in medical procedures, ultimately enhancing the success of surgeries and improving patient outcomes.

- Q:What are the main characteristics of tool steel?

- Tool steel, a specialized type of steel, is specifically engineered for the manufacturing of tools such as drills, dies, and cutting instruments. It boasts several key attributes that render it suitable for these applications. Primarily, tool steel is renowned for its exceptional hardness. It contains a substantial amount of carbon, typically ranging from 0.5% to 1.5%, which contributes to its hardness. This hardness enables tool steel to withstand wear and abrasion, making it perfect for cutting and shaping materials. Another crucial characteristic of tool steel is its remarkable toughness. It possesses the ability to endure high impact and shock loads without fracturing or breaking. This toughness is vital in tooling applications where tools are subjected to heavy loads and forces. Tool steel also exhibits superb heat resistance. It possesses a high melting point, allowing it to retain its strength and hardness even at elevated temperatures. This heat resistance is essential in applications where tools are exposed to high temperatures during cutting or shaping processes. Furthermore, tool steel possesses excellent dimensional stability and machinability. It experiences minimal distortion and shrinkage during heat treatment, ensuring that the tool retains its shape and size. Additionally, tool steel is easily machined, enabling the production of intricate shapes and designs. Overall, the prominent characteristics of tool steel encompass high hardness, toughness, heat resistance, dimensional stability, and machinability. These properties establish tool steel as an ideal material for the production of tools that necessitate high strength, durability, and performance.

- Q:What are the unique properties of stainless steel?

- Stainless steel possesses several unique properties that set it apart from other metals. Firstly, it is highly corrosion resistant, making it ideal for applications in environments with high moisture or chemical exposure. Secondly, stainless steel has excellent strength and durability, allowing it to withstand extreme temperatures and heavy loads. Additionally, it is hygienic and easy to clean, making it popular in industries such as food processing and medical equipment. Lastly, stainless steel is aesthetically pleasing, with a shiny and polished appearance that can be maintained over time.

- Q:What are the different forging techniques for special steel?

- For special steel, different forging techniques can be utilized depending on the desired properties and characteristics of the final product. Some commonly employed techniques are as follows: 1. Open-die forging, also known as smith forging or hand forging, involves shaping the steel between two flat dies or anvils. The metal is heated and hammered repeatedly until it achieves the desired shape. This technique is suitable for larger and more intricate components like shafts, cylinders, or discs. 2. Closed-die forging, also called impression-die forging, entails shaping the steel within a set of dies that contain the desired shape. The metal is placed between the dies and compressed under high pressure. Closed-die forging is often used for smaller, more intricate components, providing greater control over the final shape and dimensions. 3. Roll forging involves passing the steel between two or more rotating rolls to shape it. The rolls exert pressure on the metal, causing it to deform and acquire the desired shape. This technique is commonly used for producing long, cylindrical components such as axles, bars, or rings. 4. Upset forging involves deforming the steel by reducing its length and increasing its cross-sectional area. The metal is placed between two dies and axially compressed, resulting in bulging and the desired shape. Upset forging is commonly utilized for producing short, thick components like bolts, screws, or nuts. 5. Press forging, similar to closed-die forging, employs a hydraulic or mechanical press to shape the steel. The metal is placed between two dies and compressed under high pressure, allowing controlled deformation. Press forging enables precise control over the shaping process and is often employed for producing high-quality and complex components. Each of these forging techniques possesses its own advantages and limitations, and the choice of technique relies on factors such as size, complexity, and desired properties of the final product. By selecting the appropriate forging technique, manufacturers can ensure that special steel components meet the required specifications and performance standards.

- Q:How is special steel used in the textile industry?

- Special steel is used in the textile industry for various purposes such as manufacturing machinery components, needles, and cutting tools. It provides durability, strength, and resistance to wear and tear, ensuring the efficient operation of textile machinery and improving the overall production process. Additionally, special steel is utilized in the production of textile blades, which are crucial for precision cutting and shaping of fabrics.

- Q:How does special steel compare to stainless steel?

- Special steel and stainless steel are two distinct types of steel with different properties and applications. While stainless steel is known for its corrosion resistance, special steel is recognized for its exceptional strength and durability. Special steel is often used in high-stress environments where resistance to wear, impact, or extreme temperatures is crucial. On the other hand, stainless steel is preferred in applications where resistance to rust and staining is essential, such as in kitchen appliances or medical instruments. Therefore, the choice between special steel and stainless steel depends on the specific requirements and desired characteristics for a particular application.

- Q:How does the heat treatment process affect the hardness of special steel?

- The hardness of special steel is greatly influenced by the heat treatment process. This process involves heating the steel to a specific temperature, maintaining it at that temperature for a certain period, and then cooling it at a controlled rate. By altering the microstructure of the steel, the heat treatment process impacts its hardness. Quenching, which is one of the most commonly used heat treatment techniques, involves rapidly cooling the steel. This results in the formation of martensite, a hard and brittle microstructure. The rapid cooling prevents the formation of softer microstructures like pearlite or ferrite, leading to an increase in the steel's hardness. Tempering is another heat treatment process that affects the hardness of special steel. After quenching, the steel is often tempered to decrease its brittleness and enhance its toughness. This involves reheating the quenched steel to a lower temperature and then slowly cooling it. Through this process, some of the martensite transforms into a more ductile microstructure, such as tempered martensite or bainite. These microstructures retain some of the hardness of martensite while also providing improved toughness and resistance to fracture. To summarize, the heat treatment process plays a significant role in determining the hardness of special steel. Quenching increases hardness by forming martensite, whereas tempering balances hardness with improved toughness. By adjusting parameters such as temperature and cooling rate, the desired hardness and mechanical properties can be achieved for different applications of special steel.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Mild Q195/215 CNBM Steel Billets Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords