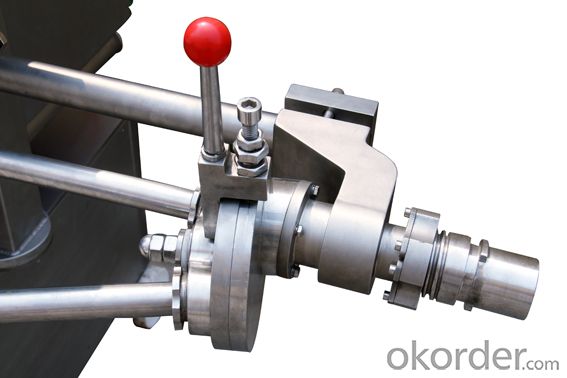

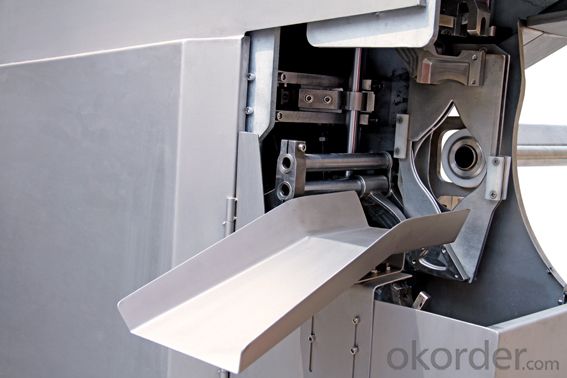

mechanical greatwall double clipper series

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Automatic Double Clipper JCK series built with the Japan Panasonic servo motor as the drive system, the man-machine interface from Taiwan and the Japan Mitsubishi PLC. It is designed with the state-of-the-art forced wire-feed mechanism, featuring precise and clear action.

Advantages:

Ranked as Top Leader in China in terms of productivity and equipment faults.

Tough stainless steel Design construction guarantee extensive machine life.

Ensures resistance to aggressive cleaning.

Controlled electronically via a PLC and servo-frequency inverter.

Easy touch means simple and convenient machine operation.

Friendly user interface makes the machine control easier.

Operator is quided intuitively through the flat menu structure with informative and can easily control the complete machine at the touch of a finger.

Programs set of parameters easily managed screen and settings speed up product change rapidly.

- Q: Industrial and commercial electric heating food processing equipment, including water purifiers?

- The common water purifier does not include filtration and has no heating function

- Q: Food processing equipment where relatively reliable ah?

- Mainly engaged in frying machines, frying machines, assembly lines, sterilization equipment, cooking equipment and other food machinery processing, is the food processing industry at home and abroad, a leading supplier of fried equipment. It can meet the production needs of foreign enterprises, joint ventures and domestic large and medium-sized enterprises. Products sold throughout the country, and has been exported to many countries and regions, China has become one of the forefront of the food deep fried machinery and equipment manufacturers, service providers, in the same industry enjoys a high reputation.

- Q: Several kinds of new food processing machinery

- The 6BH - 1500 type peanut shelling machine: Shandong province Rizhao City beikuo town Fu Tian Zhuang peanut shelling machine factory and Rizhao City agricultural machinery maintenance management station cooperative development and production of Futian brand 6BH - 1500 type peanut shelling machine, recently passed the expert appraisal by the Shandong provincial agricultural machinery testing and appraisal organization, and the agriculture of Shandong Province Machinery Management Office issued the "agricultural machinery promotion certificate", it has been put into production.

- Q: What standards should be used for food processing water equipment?

- (1) soft water means less water dissolved by minerals, such as rain water and distilled water.(2) hard water refers to minerals with more water, especially calcium, salt, magnesium, salt and other salts. According to minerals contained in the waterHard water can be divided into temporary hard water and permanent hard water, depending on the quantity and composition of the substance. Temporary hard water: calcium and magnesium salts in water can be boiled, boiled, precipitated, stained, and decomposed into carbon dioxide and softened. 2 Permanent Water: calcium salts and magnesium salts in water can not be removed by heating.(3) alkaline water refers to water whose pH is more than 7.(4) acid water is water whose pH is less than 7.(5) salt water refers to water containing more sodium chloride.Water hardness refers to the amount of calcium dissolved in water. The total content of magnesium and other salts. Hardness degree of water is often used to indicate the degree of hardness of water in our country. 1 degrees D refers to 1L containing 10mg calcium oxide in water. The legal unit of measurement for water hardness is mmo1/L, and 1 degrees D equals 0.35663mmo1/L. Hardness can be divided into six kinds of water: 1 extremely soft water, 0~4 degrees d:2 soft water: 4~8 degrees D; 3 medium hard water, 8~12 degrees d:4 soft hard water, 12~18 degrees D; 5 hard water, 18~30 degrees D; 6 extremely hard water, more than 30 degrees D.

- Q: I would like to ask the food processing industry what mechanical hand, recommend?

- The food processing industry has requirements for food contact parts, corrosion protection and pollution prevention

- Q: What are the benefits of the advent of food processing machinery?

- High efficiency, automatic processing of food can be achieved.

- Q: What is the future of the food machinery industry?

- According to a survey of global major food processing machinery company of international famous research institutes, boldly predicted that the food processing industry will revolutionize the future ten years, which will bring new opportunities for the food processing industry. The development of food machinery industry is not currently Everything is going smoothly. food processing enterprises in China, the scale is relatively low, the shortage of funds, according to statistics, food processing machinery enterprises in China up to 45, but mechanical application is not common, mostly relatively backward equipment or relatively backward technology, seriously hindered the development of the industry. At present, many of China's food processing machinery enterprises will market alignment abroad, but Japan, Germany and Italy in food processing machinery industry occupies a very important position, their technical level of China's food processing machinery market has an overwhelming advantage, foreign market competition is fierce.

- Q: What are the disadvantages of spiral conveyors in food processing machinery compared with those of belt conveyors and bucket conveyors?

- . Belt conveyors are widely used in home appliances, electronics, electrical appliances, machinery, tobacco, injection molding, post and telecommunications, printing, food and other industries.

- Q: What kind of machines do you need to buy a small meat processing plant?

- See what you want to do.. The following provides equipment requirements for several meat products. Should be equipped with the production capacity of packaging equipment and transport tools.

- Q: Classification of food machinery

- Food machinery according to its nature can generally be divided into general food machinery, food machinery, food packaging machinery, food testing machinery

Send your message to us

mechanical greatwall double clipper series

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot Searches

Related keywords