MDF Board Wood Decorative Furniture Moulding Machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

MDF board wood decorative furniture moulding machine

Products detail

MDF board wood decorative furniture moulding machine is applicable for panel/ furniture plant or wood-based further processing to laminate decoration paper on particle board, MDF board with advanced technology.

MDF board wood decorative furniture moulding machine is availale according to your requirements!

Features

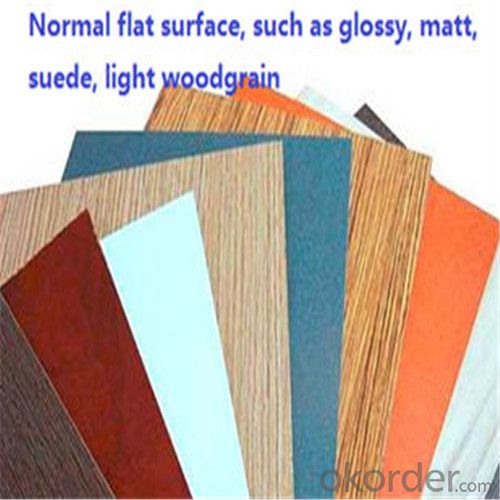

MDF board wood decorative furniture moulding machine is used to produce laminate board with a wide array of texture, from flat surface to light/deep emboss or synchronized grain engraving effects.

It is also suitable for laminating decorative paper,wearable paper and balance paper in both sides of HDF board to produce laminate flooring.

The applications (MDF board wood decorative furniture moulding machine are for)

MDF board wood decorative furniture moulding machine for Laminating furniture board.

- The covering materials are melamine paper, veneer etc.

- The core boards are MDF / HDF / Particle Board.

Products display

Packing & Shipping

Package:MDF board wood decorative furniture moulding machine will be packed according International MDF board hot press machine standard packing

Delivery : about 15 days after receive deposit payment

Certifications

FAQ

Q:What is the material of your products?

A:The main material are steels, oil cylinder and other. We can also choose material as customers’ requirement.

4.Q:How can I kown more about the press machine?

A: We are honored to send you some pictures and vedio about our machine. And we welcome every customer visit our factory.

5.Q:How does your factory do regarding quality control?

A:Quality is priority. Factory director always attach great importance to quality controlling from the very beginning to the very end. Our factory has gained ZDHY, ISO9001 authentication.

- Q: How long is the service life of an air compressor? Are there any uniform standards?

- Let's put it this way! Five years is a good period, that is to say at this stage no fault, five to ten years, some small problems do not affect the normal work, ten years after the luck to see you, this period usually bad to overhaul it is ready for a bar!

- Q: Does the compressor stop when the air compressor is unloaded?

- There are two cases,First: the gas consumption of the pipeline is 0, the pressure in the pipeline is increased, and the exhaust pressure of the air compressor is automatically unloaded when the exhaust pressure rises. Unloading time,Normal operation of air compressor. Only the intake valve is closed, and the inlet valve is a small hole on the butterfly valve (no hole will not close).The oil release valve on the oil separation cylinder opens and is discharged to the intake valve (which is said to be atmospheric), and the pressure of the oil separation cylinder is smaller. Therefore, the minimum pressure valve for the gas supply in the direction of the oil separation cylinder is closed so that the air supply is not backward.Second: you press down, attention is not an emergency stop.Air compressor motor will not immediately power off, but will turn off the intake valve, open the vent valve, usually through about 7S, after the completion of the bleeding stop.Special circumstances, if the emergency state press the "stop" button, the air compressor motor immediately power-off, air release valve to open the bleeding.

- Q: What type of engine oil does the air compressor require?

- The main types of empty compressor, small air pump general machine oil on the line, not too high viscosity, 0.6 more than to use air compressor oil, high pressure gas production factory continuous operation or large air compressor according to the instructions made of oil, can not replace the selected model is 32, or 46, and mineral oil is a semi synthetic oil synthetic oil, according to the size of the region and the selection of air compressor.

- Q: A 7.5KW air compressor, 4 3.5KW motors, how many power generators do I need?

- Air compressor, motor 21.5kw, 30kW power generation units can be used, there are some balances, you can only add some equipment to leave room. If the generator set is too large, it is uneconomical to consider economically, and the maintenance cost is also high.

- Q: The guarantee value of the oil content in the air of the screw compressor

- The guarantee value of the oil content in the air of the screw type air compressor is about 0.1%.The screw air compressor with high reliability for screw air compressor has become an inevitable trend to replace the piston compressor with many wearing parts and poor reliability. According to statistics: Japan's screw compressor in 1976 accounted for only 27%, while in 1985 it rose to 85%. The market share of screw compressors in the western developed countries is 80%, and keeps rising. Screw compressor has the advantages of simple structure, small size, no wearing parts, reliable work, long service life and simple maintenance.

- Q: How much money for air compressor

- Air compressor procurement costs, this is the most intuitive, the first to reflect, according to the customer's budget, is to buy imported air compressor, or domestic air compressor, a comparison, an inquiry, it came out. For example, the import of three major air compressor brand, brand sound, prices naturally high; domestic high-end brands, quality is good, the price is more affordable.

- Q: How will the Hitachi BEBICON air compressor?

- If the air exhaust pressure and exhaust volume are determined, please select the appropriate type according to the specifications.

- Q: What does air conditioning press mean?

- The working circuit of the air conditioning compressor is divided into an evaporation zone (a low-pressure zone) and a condensing zone (a high-pressure zone). The indoor and outdoor units of the air conditioner belong to the low voltage or high pressure area (depending on the working state). The refrigerant flows from the high pressure zone to the low pressure zone, through the capillary jet into the evaporator, the pressure falls sharply, and the liquid refrigerant immediately turns into a gaseous state and absorbs a large amount of heat in the air by the heat sink. In this way, the air conditioning compressor continues to work, and continuously to the low pressure zone at one end of the heat absorbed into the refrigerant, and then sent to the high-pressure zone, distributed to the air, play a role in regulating the temperature.

- Q: What does "1p.2p" mean by air compressor?

- Generally speaking, a habit is equal to the cooling capacity of 2500W (25 models), 1.5 Piyue is equal to the amount of 3500W (35 models). 26 models, about 1.1, 27 models for 1.2, 28 models of about 1.3, 32 models for 1.4; 33 models of about 1.5, and 36 models for the big 1.5.

- Q: What is the meaning of the breaking pressure and the closing pressure in the air compressor? How do you adjust the air pressure and pressure switch?.

- Because the air compressor is a pressure factor automatic control switch, disconnect pressure is to reach this pressure, the air compressor does not work or no output, it should be the highest value

Send your message to us

MDF Board Wood Decorative Furniture Moulding Machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords