Automatic Melamine Plywood Plate Hot Press Machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Automatic melamine plywood plate hot press machine

Products detail

Automatic melamine plywood plate hot press machine is applicable for panel/ furniture plant or wood-based further processing to laminate decoration paper on particle board, MDF board with advanced technology.

Automatic melamine plywood plate hot press machine is availale according to your requirements!

Features

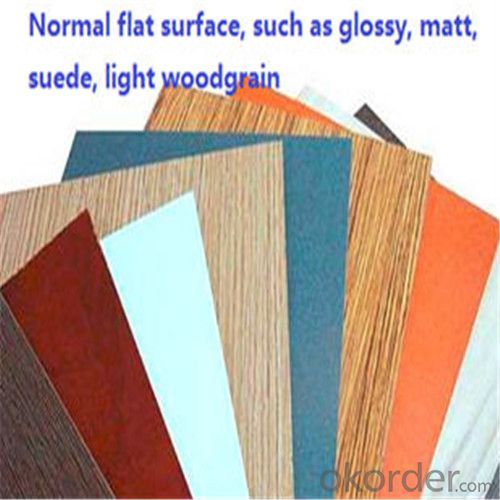

Automatic melamine plywood plate hot press machine is used to produce laminate board with a wide array of texture, from flat surface to light/deep emboss or synchronized grain engraving effects.

It is also suitable for laminating decorative paper,wearable paper and balance paper in both sides of HDF board to produce laminate flooring.

The applications (Automatic melamine plywood plate hot press machine are for)

Automatic melamine plywood plate hot press machine for Laminating furniture board.

- The covering materials are melamine paper, veneer etc.

- The core boards are MDF / HDF / Particle Board.

Products display

Packing & Shipping

Package:Automatic melamine plywood plate hot press machine will be packed according International MDF board hot press machine standard packing

Delivery : about 15 days after receive deposit payment

Certifications

FAQ

Q:What is the material of your products?

A:The main material are steels, oil cylinder and other. We can also choose material as customers’ requirement.

4.Q:How can I kown more about the press machine?

A: We are honored to send you some pictures and vedio about our machine. And we welcome every customer visit our factory.

5.Q:How does your factory do regarding quality control?

A:Quality is priority. Factory director always attach great importance to quality controlling from the very beginning to the very end. Our factory has gained ZDHY, ISO9001 authentication.

- Q: What is the minimum power of screw air compressor?

- The minimum power of the screw air compressor is 5.5KW.The screw air compressor adopts a complete set of screw type air compressor, only a single power supply connection and compressed air connection, and a built-in cooling system, so that the installation work is greatly simplified. Screw type air compressor with its high efficiency, high efficiency, maintenance free, highly reliable and so on, consistently provide quality compressed air for all walks of life.

- Q: What is the use of air compressors?

- The air force a, the traditional pneumatic tools, drilling machine, pneumatic, pneumatic wrench, pneumatic sandblastingB, instrument control and automation equipment, such as tool change in machining center, etc.C, vehicle braking, door and window opening and closingD, air-jet loom with compressed air blowing weft to replace the shuttleE, food and pharmaceutical industry, the use of compressed air mixing slurry F, large marine diesel engine startG, wind tunnel experiment, underground channel ventilation, metal smeltingH, oil well fracturingI, high pressure air blasting mining

- Q: What happens when the air compressor is plugged in and does not work?

- There is a motor terminal box, there is a button on the box inside, if it is closed, please press the button in the button like air switch, power supply circuit will automatically trip, this is one reason the motor does not work;

- Q: What's the load on the air compressor?

- Empty transplanting: that is, the air compressor motor is idle and does not produce gas;Load: the air compressor is used as power equipment, and the compressed air generated by it drives the operation of some equipments (such as wind drill, cylinder, etc.)

- Q: The difference between BLT and BLX for screw compressors

- Equipped with low, BMW 7 series and BMW 5 Series difference

- Q: Two screw air compressor and single-stage screw compressor, which kind of energy efficiency better?

- The two stage compression is better, and the two stage compressed screw air compressor is more efficient than single stage compression, and the efficiency is about 10%.

- Q: Air compressor trip problem

- The following may be the cause of this failure: (for reference only)1. voltage is too low, can be detected by voltmeter.2. transformer capacitance is large enough, in the summer due to the use of air conditioning and electrical appliances, may lead to inadequate capacity of transformers3. air compressor temperature is too high, also can cause tripping4. check the main current, the general air pressure opportunity, the main motor protection function.5., the main engine is not running smoothly (due to poor environment, maintenance is not in place or bearing problems caused)6. check the oil level of the air compressor.

- Q: What is the difference between air compressor water cooling, oil cooling and air cooling?

- Oil cooling is the use of oil lubrication, cooling, sealing machine, and want to keep at a proper temperature to oil cooling, air cooling and water cooling so there is divided, air cooling is the use of Aluminum Cooler by fan forced convection to achieve the effect of cooling oil, and water is outside of the spiral copper copper oil. "Inside, water and water > heat exchange to achieve cooling effect, cooling machine installation is relatively simple, but influenced by the environment, the need for frequent maintenance in poorly ventilated or relatively poor place, otherwise easy to high temperature; water need to install cooling tower pump water cooling machine, but the environmental requirements is not high and stable, if small machine (50HP) air-cooled large machine can suggest water will be more stable.

- Q: Disadvantages of centrifugal air compressor

- In 50s China had been able to produce centrifugal compressor, from the beginning of 70s in the petroleum chemical plant, large chemical fertilizer plant, centrifugal compressor, the introduction of a series of high performance, high pressure, made use of rich experience, and in the digestion and absorption based on the introduction of technology greatly enhanced their research, design and manufacturing capabilities.

- Q: How to remove the moisture of the air compressor?

- Higher requirements require the use of cold dryers.Higher requirements require the use of cold and dry dryers + adsorption dryers.

Send your message to us

Automatic Melamine Plywood Plate Hot Press Machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches