Automatic Plywood Plate Hot Press Machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Automatic plywood plate hot press machine

Products detail

Automatic plywood plate hot press machine is applicable for panel/ furniture plant or wood-based further processing to laminate decoration paper on particle board, MDF board with advanced technology.

Automatic plywood plate hot press machine is availale according to your requirements!

Features

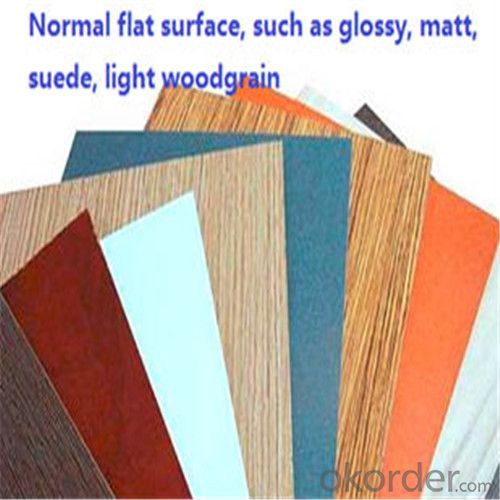

Automatic plywood plate hot press machine is used to produce laminate board with a wide array of texture, from flat surface to light/deep emboss or synchronized grain engraving effects.

It is also suitable for laminating decorative paper,wearable paper and balance paper in both sides of HDF board to produce laminate flooring.

The applications (Automatic plywood plate hot press machine are for)

Automatic plywood plate hot press machine for Laminating furniture board.

- The covering materials are melamine paper, veneer etc.

- The core boards are MDF / HDF / Particle Board.

Products display

Packing & Shipping

Package:Automatic plywood plate hot press machine will be packed according International MDF board hot press machine standard packing

Delivery : about 15 days after receive deposit payment

Certifications

FAQ

Q:What is the material of your products?

A:The main material are steels, oil cylinder and other. We can also choose material as customers’ requirement.

4.Q:How can I kown more about the press machine?

A: We are honored to send you some pictures and vedio about our machine. And we welcome every customer visit our factory.

5.Q:How does your factory do regarding quality control?

A:Quality is priority. Factory director always attach great importance to quality controlling from the very beginning to the very end. Our factory has gained ZDHY, ISO9001 authentication.

- Q: The air compressor doesn't start

- Check that the fuse is burned out,

- Q: What is the production process of the hydraulic press?

- Therefore, there are also a variety of control methods, the basic method of electromechanical transmission common automatic control is mainly: the use of motor current of main circuit to control the motor speed of the notice;; according to the time interval control and according to the working machinery to control the movement of the hydraulic system, in accordance with the basic structure of the hydraulic circuit, can the hydraulic system is divided into open system and closed system.

- Q: How can the water in a large air compressor pipe be completely removed?

- The main source of water in the air compressor pipe is that the air is compressed and heated at high temperature. It passes through the pipeline and cools slowly. The water molecules in the air condense and become condensed water. There are many ways to solve condensed water in compressed air.

- Q: What happens when the air compressor is plugged in and does not work?

- There is a motor terminal box, there is a button on the box inside, if it is closed, please press the button in the button like air switch, power supply circuit will automatically trip, this is one reason the motor does not work;

- Q: Piston air compressor, breather valve, oil injection

- As the case is, the air compressor is of poor quality. This machine may be aluminum piston, aluminum connecting rod, cylinder radiator less or small area, poor heat dissipation, the inlet and exhaust valve group seal is not good, produce high temperature. Large pressure injection in crankcase. Not suitable for long time use, such as factory recommended replacement

- Q: Excuse me, what's the difference between air compressor and air pump?

- Their principles are basically the same. Only in the structure of the difference, the air compressor intake and exhaust valves, the air pump exhaust is generally straight. It is better to use air compressor.

- Q: There are several reasons for the overload of the air compressor main engine

- External pressure sensor failure: zero drift, wiring error, the upper and lower limit is not correct or set back, according to different sensors have different methods of setting and troubleshooting

- Q: Is the air compressor good?

- The market scale of the air compressor industry in our country has increased by more than 8%, and the growth rate has exceeded 28% In 2010-2011 years, and the market scale has expanded rapidly. However, in such a huge market, in the past a long period of time, the majority of foreign enterprises grasp the market. In 2009, China air compressor industry total production of nearly 400 enterprises, the number of domestic enterprises to achieve sales revenue of nearly 90%, a total of about 6 billion yuan, accounting for 40% of the entire industry; the number of foreign invested enterprise is close to 10%, total sales revenue of about 9 billion yuan, accounting for 60% of the entire industry.

- Q: How to determine the compressor is a few compression?

- The selection of air compressor is mainly based on the working pressure and flow of the pneumatic system.The working pressure of gas source should be about 20% higher than the maximum working pressure in pneumatic system, because the distance loss and local loss of the gas supply pipeline should be considered. If the work pressure in some parts of the system is low, a pressure reducing valve can be used to supply the gas. The rated exhaust pressure of air compressor is divided into low pressure (0.7~1.0MPa), medium pressure (1.0~10MPa), high pressure (10~100MPa) and ultra high pressure (over 100MPa), which can be chosen according to the actual demand. Common use pressure is 0.7-1.25.First of all, according to the characteristics of the air compressor requirements, select the type of compressor. Then, the output pressure PC and the suction flow QC of the air compressor are determined according to the two parameters of the working pressure and the flow rate required by the pneumatic system, and finally the model of the air compressor is selected.

- Q: How to maintain the air compressor ah? For example: how often does the oil change?

- How to maintain the air compressor?Primary maintenanceFirst level maintenance is a daily work. Usually before class, after class and on duty. The purpose is to ensure the normal operation of equipment and civilized and orderly work site.

Send your message to us

Automatic Plywood Plate Hot Press Machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches