Auto Bamboo Plywood Board Furniture Manufacturing Machinery

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Auto bamboo plywood board furniture manufacturing machinery

Products detail

Auto bamboo plywood board furniture manufacturing machinery is applicable for panel/ furniture plant or wood-based further processing to laminate decoration paper on particle board, MDF board with advanced technology.

Auto bamboo plywood board furniture manufacturing machinery is availale according to your requirements!

Features

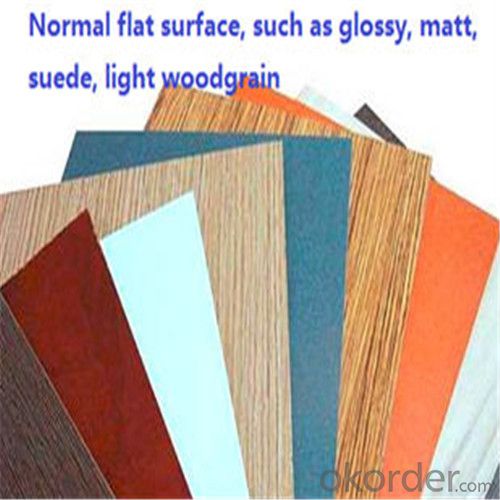

Auto bamboo plywood board furniture manufacturing machinery is used to produce laminate board with a wide array of texture, from flat surface to light/deep emboss or synchronized grain engraving effects.

It is also suitable for laminating decorative paper,wearable paper and balance paper in both sides of HDF board to produce laminate flooring.

The applications (Auto bamboo plywood board furniture manufacturing machinery are for)

Auto bamboo plywood board furniture manufacturing machinery for Laminating furniture board.

- The covering materials are melamine paper, veneer etc.

- The core boards are MDF / HDF / Particle Board.

Products display

Packing & Shipping

Package:Auto bamboo plywood board furniture manufacturing machinery will be packed according International MDF board hot press machine standard packing

Delivery : about 15 days after receive deposit payment

Certifications

FAQ

Q:What is the material of your products?

A:The main material are steels, oil cylinder and other. We can also choose material as customers’ requirement.

4.Q:How can I kown more about the press machine?

A: We are honored to send you some pictures and vedio about our machine. And we welcome every customer visit our factory.

5.Q:How does your factory do regarding quality control?

A:Quality is priority. Factory director always attach great importance to quality controlling from the very beginning to the very end. Our factory has gained ZDHY, ISO9001 authentication.

- Q: What is the relationship between the screw compressor pressure and the exhaust volume?

- The screw air compressor adopts a complete set of screw type air compressor, only a single power supply connection and compressed air connection, and a built-in cooling system, so that the installation work is greatly simplified. Screw type air compressor with its high efficiency, high efficiency, maintenance free, highly reliable and so on, consistently provide quality compressed air for all walks of life.The screw type air compressor adopts a complete set of configuration, only needs a single power supply connection and a compressed air connection, and has a cooling system, so that the installation work is greatly simplified. Screw type air compressor with its high efficiency, high efficiency, maintenance free, highly reliable and so on, consistently provide quality compressed air for all walks of life. The screw compressor assembly in the screw air compressor is manufactured with the latest CNC grinding machine, and the on-line laser technology is adopted to ensure the precise manufacturing tolerances. Its reliability and performance ensure that the running cost of the compressor has been extremely low during the service life. Adjusting compressors, integral compressors and desiccant series are new products in the L/LS series compressors.

- Q: What is the automatic drain valve of the air compressor?

- DrainageThe principle is: compressed air compressed air is saturated, when the temperature is reduced, there is water in the compressed air from the condensate drain out, gathered at the bottom of a certain amount of time, the floating ball drain valve to open water discharge, the floating ball no buoyancy after closure, so the cycle;

- Q: Air compressor high temperature, how's going on?

- The impact of the surrounding environment to the air compressor air compressor cooling, such as air compressor from the wall or obstacles too near, there are other sources of heat, air compressor air compressor operation when the front door or door open, leading to the fan can not form a strong airflow, all these will lead to air compressor heat environment ventilation condition.

- Q: Reuse process is always over temperature, I do not know what the problem is.

- There are many reasons for overheating fault of air compressor. The main reasons are as follows:1, insufficient oil or oil tank components will cause abnormal oil temperature rise, thus causing overheating faults. Such as:(1) insufficient oil supply: first, check the oil filter and the oil separator is blocked. Second, check whether the oil regulator is normal and increase fuel injection when necessary.(2) the oil stop valve does not work properly: the oil stop valve is generally two to two normally closed solenoid valve, start stop open, closed, to avoid downtime when oil and gas in the barrel of oil to spray into the nose, and ejected from the air inlet.(3) the work of the thermal control valve is out of order: the heat control valve is installed in front of the oil cooler, and its function is to maintain the exhaust temperature above the pressure dew point. The main reason of failure, one is to change the elastic coefficient on the spool size two thermal spring fatigue, can not change with temperature is normal operation; two body wear, the valve stuck or action is not in place and can not normally closed. Can be repaired or replaced according to the situation.

- Q: Does the gas separator of the air compressor belong to special equipment? Is it only necessary to provide the quality supervision and inspection report?

- Belong to special equipment, need to provide installation quality supervision and inspection report and the local safety supervision department for the record of use certificate

- Q: What is the function of air compressor? Why are there air compressors in general sewage stations? What is the main function?

- The sewage station is also a kind of air compressor for aeration, and it is the key equipment in the sewage station. The main function is as follows:A, gas transport, the air through the aeration system to the biochemical pool, providing biochemical reaction required oxygen, and maintain the concentration of dissolved oxygen;B, compressed air as a power to provide agitation for the biochemical pool, so that sludge and sewage sufficient contact;C, assisted in the biochemical pool of carbon dioxide, volatile acid, separation nitrogen and other gaseous products.

- Q: The refrigerator compressor doesn't work. How much does it cost to change?

- General repair fee and compressor is 400-600 yuan full cost.

- Q: There are several reasons for the overload of the air compressor main engine

- Oil separator: do not think you do not change the new thing for a long time not blocked, the dirty environment, oil and gas barrels inside the impurities are easy to plug the oil. One of my clients is not using the factory parts, but it took less than 3000 hours to stop the machine. After the replacement of the new parts, the pressure is normal.

- Q: What does the pressure dew point of an air compressor mean?

- When the moist air is compressed, the water vapor density increases and the temperature rises. When the compressed air cools, the relative humidity increases. When the temperature continues to drop to 100% relative humidity, water droplets are released from the compressed air. The temperature at this point is the pressure dew point of the compressed air".

- Q: The process and principle of laminator

- No matter what kind of operation the laminator applies, the working principle is the same. That is, applying a certain amount of pressure on the surface of the multilayered material that tightly bonds them together. The difference is that depending on the purpose of laminating, the conditions of bonding are different.

Send your message to us

Auto Bamboo Plywood Board Furniture Manufacturing Machinery

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords