JXP-180 Automatic liner Bottle Rinser

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Product Details:

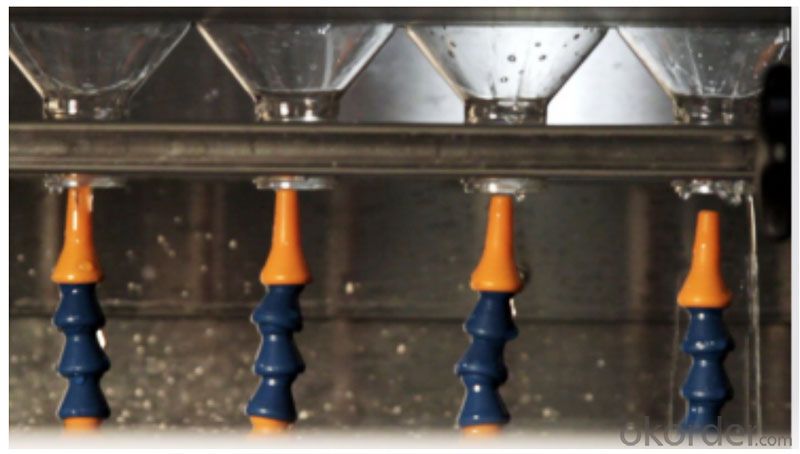

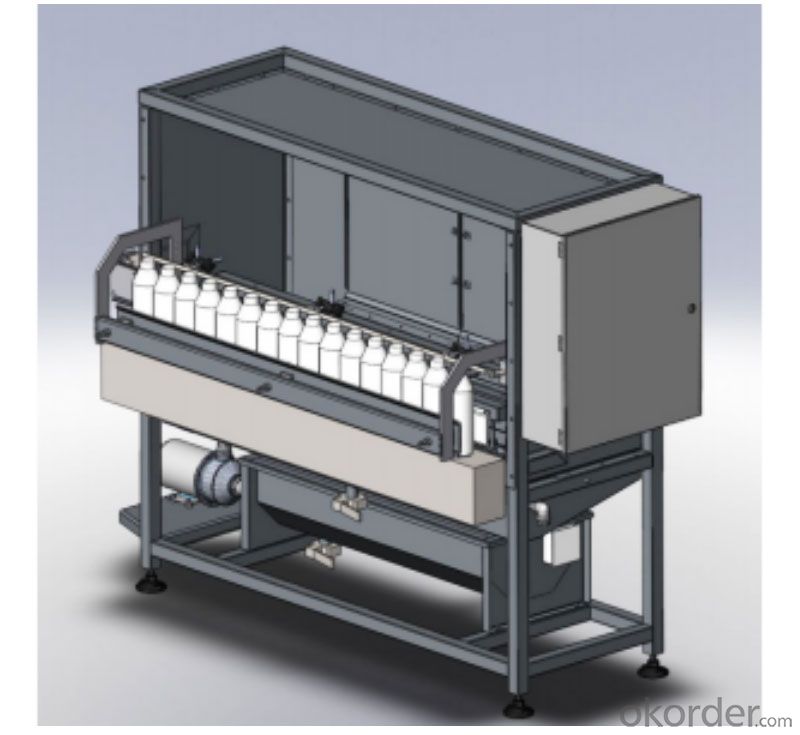

JPACKS Automatic Linear Water Rinser is used to remove dust particles and other dry contaminants from clean containers. Typically used in the bottled water industry, this Water Rinser can also be utilized in a variety of other industries that require rinsed containers prior to filling. The containers are automatically indexed into the Rinser. The grippers capture the containers and then invert them 180 degrees over the adjustable Rinse Heads. High pressure jets individually rinse the containers internally with product water or customer-supplied rinse media. Once rinsed, containers are briefly drained and are reverted back onto the conveyor. The Automatic Linear Water Rinser comes standard with PLC Controls and color touch screen HMI, Pneumatic Indexing Gates, No bottle/No rinse and Bottle Backup Sensors, plus many more. Additional options are available for even more versatility.

2、Standard Features:

1 Fingertip knob adjustable jets for different bottle width

2 PLC Controls with color touch screen HMI

3 Pneumatic Indexing Gates (Entry and Exit)

4 Overall electronic production counter

5 No bottle/No rinse Sensor

6 Bottle Backup Sensor (downstream) delays operation 1.7 until jam is cleared

7 On/off and speed controls for Conveyor

8 10 memory locations for rinse and indexing recipes

9 Front panel Start and Emergency Stop

10 Mounted on 4 heavy duty casters, plus threaded leveling legs

3、Specifications:

1 Standard Construction: Heavy duty 304SS 48” frame with some anodized aluminum

2 Rinse Head: Virtually all container sizes

3 Rinse Time: Variable, typically 2 to 3 seconds per container

4 Standard Line Height: Typically 36”

5 Power Requirement: 220VAC, single phase, 30 amp, 50-60Hz

6 Air Requirement: 2CFM @ 90PSI clean, dry, compressed air

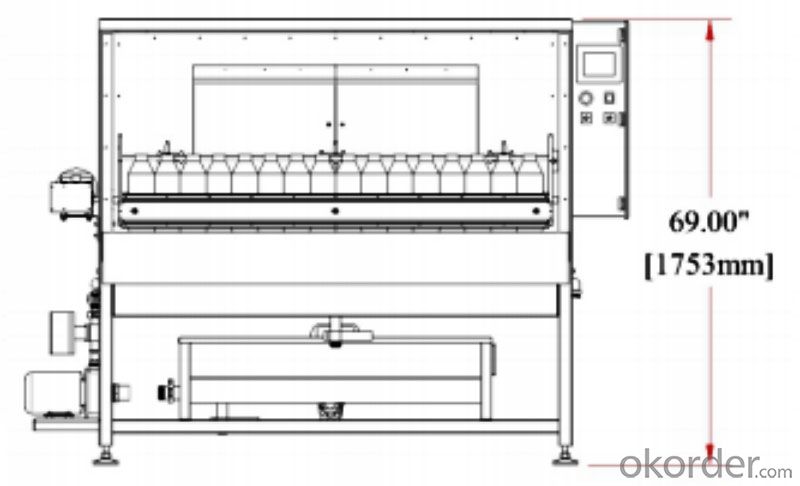

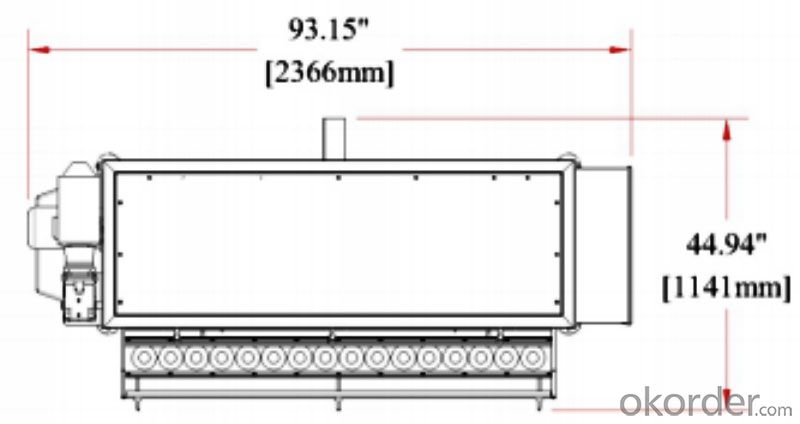

7 Dimensions & Weight: Subject to model configuration

4、Options:

1 1 to 16 Rinse Heads

2 Larger frame for more Rinse Heads

3 Air Knife

4 Custom applications

5 Special electrical requirements

6 Sanitary, hazardous, flammable and corrosive environment construction

5、Images:

FAQ

Q1: What is your delivery time?

A: Generally, the delivery time is 45-60 days after receive the deposit, big production line may take more time.

Q2: What is the payment term?

A: We accept both T/T and L/C. Most customers pay by T/T.

Q3: What kind of after-sevices do you provide?

A: If it is not big problem, we can solve it by emails, phone etc. If it can’t work, our engineers can go to overseas to install and adjust the machine and solve the problems.

- Q: What's the difference between bulk food and prepackaged food?

- Is a small workshop to provide containers, that is, pre packaged food, is to take their own containers to buy, that is, bulk food

- Q: What are the common material choices, printing options and common sense?

- Gift wine gift box: a reference type (single powder cardboard), or gray white cardboard. Larger boxes can be 250+250g mounted, gold card paper and silver cardboard. Different materials should be selected according to the actual needs and grade of the product.Printing: mostly printed in 4C+0 or 4C+1C, and can be printed with spot colors, special gold or silver.After the process: light glue, matte plastic, local UV, matte, hot platinum (metallic film with gold, silver, blue and other colors for choice) or anti-counterfeit film (so that others can not copy), and hit the bump, beer, viscosity and other process.

- Q: What is accessory material? What is the difference between it and raw material?

- Auxiliary materials are indirect materials used in manufacturing and in manufacturing, but not the main products of the product.

- Q: What plastic packaged food is safer?

- If you do not want to contact the high temperature, you can also choose PET materials and PS materials, these two can contact food directly.

- Q: How many kinds of packing are there?

- According to packaging products, materials are: paper products packaging, plastic packaging, metal packaging, bamboo and wooden packaging, glass container packaging and composite materials packaging;

- Q: What material is the vacuum packing bag, please?

- Vacuum packaging is a general term for flexible packaging composite membrane products. If the temperature is different, there will be a lot of division: there is less than 100 bactericidal, and some need 100 degrees of sterilization, and 121 degrees and 135 degrees. Of course, there is also room temperature, the choice of this temperature under the condition of the sterilization method is irradiation sterilization. And also consider the content and weight of the package to determine the reasonable use of the packaging materials. There is no static, and the right is the best.

- Q: What's the difference between the materials used in kraft paper packaging?

- Semi Kraft kraft wrapping paper: General tensile, color is also very general, if there is no requirement for appearance, you can use semi wood pulp, kraft paper.

- Q: What material or paper should I use for high-grade packaging?!

- The high-end boxes are made into handmade boxesMake India with special paper (in every big Paper Co)If there is a pattern design recommended with pearlescent paper, gold, silver in the process of doing this very good effect.MDF and industrial paperboard are best, MDF strength is better, industrial paperboard flexibility better

- Q: What's the difference between a package and a package?

- Packaging refers to the packaging of various types of containers, such as barrels, boxes, bags, bottles, etc., for the purpose of packing the goods of this enterprise. Packaging materials, such as paper, rope, wire, iron sheet, etc., these are disposable packaging materials, should be used as raw materials for accounting. Accounting items; turnover materials - packaging

- Q: Is the antistatic value of PS material (or other packing material) as small as possible?

- Not necessarily. This needs to be decided in terms of specific areas of use and requirements.The so-called antistatic refers to reach 10 between the 7-10 sides.And the 1-6 side of the 10 is generally referred to as electrical conduction.

Send your message to us

JXP-180 Automatic liner Bottle Rinser

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords