JLP-200H Automatic Bottle Unscrambler Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Product Details

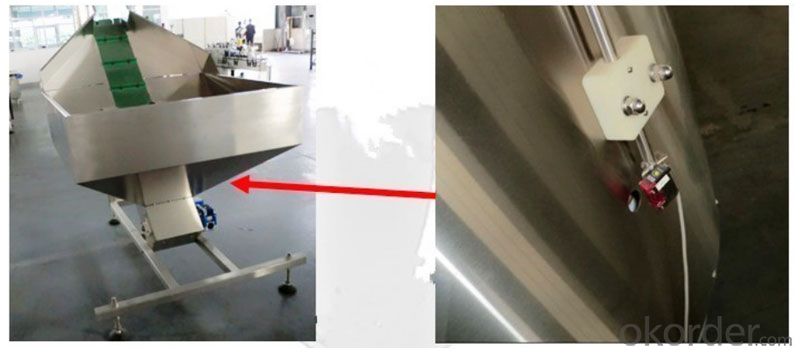

JLP-200H Automatic Bottle Unscrambler is making up of bottle elevator ,round plate,bottle rejector, bottle-arranging and the electrical cabinet . Put disordered bottles to the bottle elevator, through round plate, conveying belts, bottle arranging parts , then bottles can stand on the belts. This machine is characterized by the compact structure, simple operation principle, mature technique and stable movement.

Bottles poured into the rotator plate, with belts conveying to the unscrambling device; bottle standing orderly on the conveyor belts. This machine is of high speed, round and flat bottle both applicable. No need to change any part when changing the bottle specification. It is with auto rejecter and no-bottle alarm function.

2、Features

2.1 Simple structure and easy operation and convenient adjustment. And the normal same series machine sells on the market are much larger than us with three meters’ length and heavy weight.

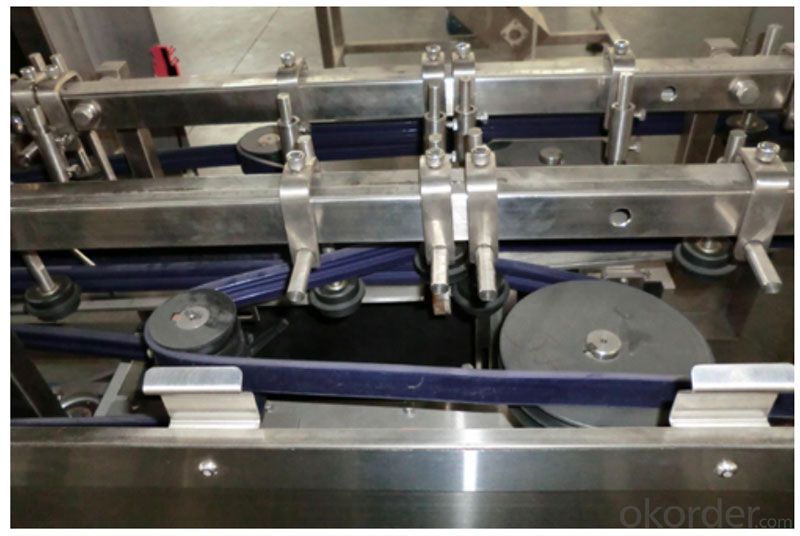

2.2 When changing different bottle size, you do not need to change anything, you only need to change the belt in the bottle hopper and adjust the space of the unscrambling structure. And it is applied to 50-1000ml.

Adjust the space of the bottle unscrambling structure according to the bottle size

2.3 Adopted the US technology, good stability and the qualified rate is 100%.

2.4 The electrical components are all imported which ensures its long service time and stability.

2.5 The whole machine is covered with organic glass, you can open all the cover for easy adjustment.

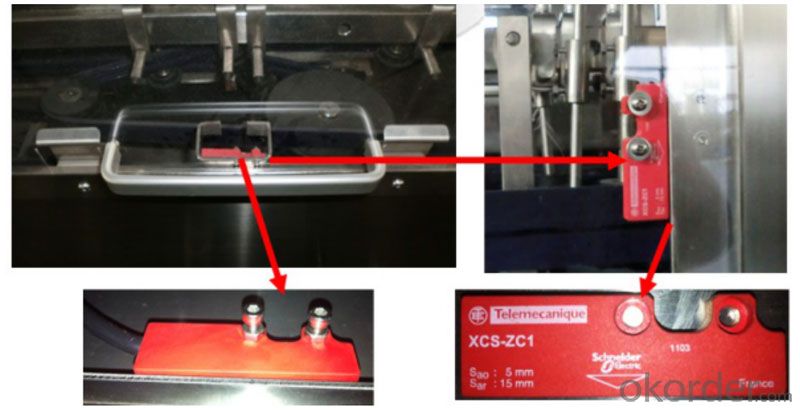

2.6 All the organic glass cover is installed with the sensor. The machine only can start when all the organic glass cover are closed,and will stop when any of the door is open.

2.7 The connecting belt in the machine are shaped in one time, not easy to broken.

2.8 Automatic bottle elevating function, you only need to put the bottles in the bottle elevator, a sensor is installed in the rotary plate, it will automatically elevates the bottles when there is not enough bottle, it will start when the bottles are enough consequently.

2.9 Coordination sensor, it will stop bottle unscrambling when there is jam of the other sections of the filling line, it will start again when the jam is cleared. It will have the perfect linkage with the other sections of the filling line.

3、Main Technology Parameter

3.1 Unscrambling Speed:≤ 200 bottles/min

3.2 Applicable Bottle Diameter:Φ45-90mm

3.3 Applicable Bottle Height:80-240mm

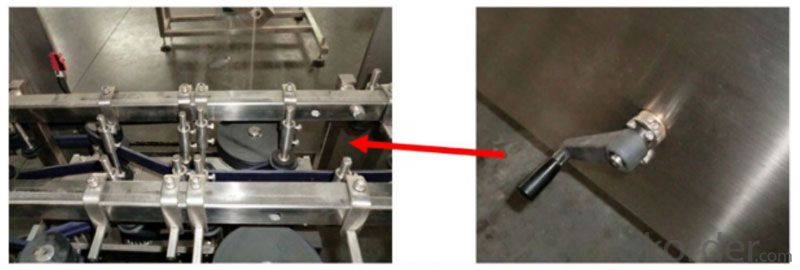

3.4 Air Pressure:0.5~0.7 MPA

3.5 Power Source:~220V、50HZ

3.6 Power:1.5KW

3.7 Bottle Unscrambler External Dimension:2600mm×1500mm×1500mm(L×W×H)

3.8 Weight:About 1250Kg

4、Allocation

4.1 Frequency converter: Japan Omron

4.2 Magnetic Switch: France Schneider

4.3 Sensor: Japan OPTEX

4.4 Power Switch: France Schneider

4.5 Cylinder: Japan SMC

FAQ

Q1: What is your delivery time?

A: Generally, the delivery time is 45-60 days after receive the deposit, big production line may take more time.

Q2: What is the payment term?

A: We accept both T/T and L/C. Most customers pay by T/T.

Q3: What kind of after-sevices do you provide?

A: If it is not big problem, we can solve it by emails, phone etc. If it can’t work, our engineers can go to overseas to install and adjust the machine and solve the problems.

- Q:What's the difference between the materials used in kraft paper packaging?

- The whole paper pulp kraft paper packaging: tension is very good, do not pull off, the color will be very uniform, is also very resistant to wear if you need outside packaging printing LOGO what, it can use kraft wrapping paper wood pulp, wood pulp and kraft wrapping paper printed very well.

- Q:What kind of fruit package do you have?

- Fruit packaging, pet plastic fruit packing box, PET material, environmental protection non-toxic, not only moisture-proof, the product is also transparent, beautiful, smooth, light weight. And there are air holes, to ensure the flow of air, but also affixed labels, indicating fruit information, so that customers at a glance.

- Q:Which industry does the packing product belong to?

- Other countries or organizations have different meanings and opinions about the meaning of packaging, but the basic meaning is consistent. They all take the function and function of packaging as their core contents and have two meanings in general:1. Containers, materials and auxiliary articles that contain the goods, that is, packages.2, on the implementation of containing and sealed, dressing and other technical activities.

- Q:What's the difference between a package and a package?

- Packaging refers to the packaging of various types of containers, such as barrels, boxes, bags, bottles, etc., for the purpose of packing the goods of this enterprise. Packaging materials, such as paper, rope, wire, iron sheet, etc., these are disposable packaging materials, should be used as raw materials for accounting. Accounting items; turnover materials - packaging

- Q:Is the antistatic value of PS material (or other packing material) as small as possible?

- Not necessarily. This needs to be decided in terms of specific areas of use and requirements.The so-called antistatic refers to reach 10 between the 7-10 sides.And the 1-6 side of the 10 is generally referred to as electrical conduction.

- Q:What are biodegradable packaging materials?

- Synthetic biodegradable packaging materials can be endowed with similar properties as traditional packaging materials, and the wide application of biodegradable packaging indicates its great potential to replace the current packaging materials.

- Q:What are the characteristics of paper holders in comparison with other packaging materials?

- The first is the protection of the environment, paper packaging raw material is waste paper pulp, not only has no pollution to the environment, but also conducive to conserve resources, protect the environment. The use range of paper tray is very extensive, with the improvement of technology paper,

- Q:What are the categories of packing materials?

- Plastic packing material: PP packing belt, PET packing belt, tearing film, winding film, sealing tape, heat shrinkable film, plastic film and hollow board;

- Q:Billycan what are the advantages compared with other packaging materials?

- Shapes: tinplate cans can be made into various shapes according to different needs, such as cans, cans, cans, circular elliptical horseshoe and trapezoid etc, can satisfy the different needs of product packaging, and the packaging container more change, promote sales.

- Q:What's bread packing? Polyethylene film, waterproof cellophane, etc.

- More importantly, the use of aluminum foil / composite or polyethylene composite or aluminum foil / polyethylene composite material. Although this type of packaging is opaque, it protects against loss of vitamin B1 in bread.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

JLP-200H Automatic Bottle Unscrambler Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords