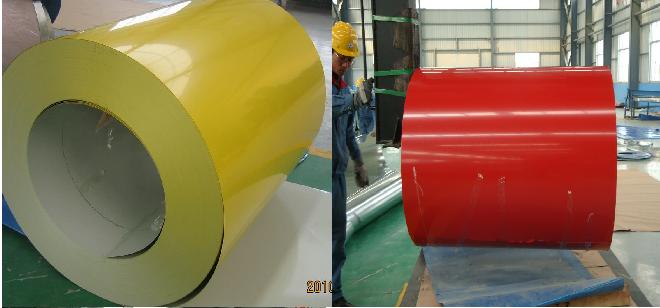

JIS G3312/ASTM A755 Prepainted Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | ASTM,JIS | Grade: | CGCC | Thickness: | 0.20mm to 1.20mm |

| Place of Origin: | Zhejiang China (Mainland) | Brand Name: | HZZN | Model Number: | PPGI0303 |

| Type: | Steel Coil | Technique: | Cold Rolled | Surface Treatment: | Galvanized |

| Application: | home appliance | Special Use: | Silicon Steel | Width: | 914/1000/1219/1200/1250mm |

| Length: | in coil | Single coil weight: | 4-6mt | Inner diameter: | 508mm or 610mm |

| Color paint coated: | top:15-25um,back:5-10um | Color: | according to RAl card | International export market: | North America, South America,Europe, Africa, Oceania, Mid East and etc |

| HS code: | 72107000 |

Packaging & Delivery

| Packaging Detail: | standard export seaworthy package. wrapped by plastic film and waterproof paper, and then fastened on wooden pallet.Or according to clients' requirement. |

| Delivery Detail: | 20-25 days after receive T/T deposit or L/C |

Specifications

1>Thickness:0.2-1.2mm

2>Zinc coating: 60-275gr/m2

3>Paint coating : 5+25um (top), 5-8um (back)

4>Paint:Beckers

5>Color:RAL

Description:

Products | JIS G3312/ASTM A755 Prepainted Steel Coil To European Union Market Without Anti-Dumping Tax |

Width | 914/1000/1219/1200/1250mm or accoding to clients' requirement |

Thickness | 0.20 ---1.20mm |

I.D. | 508mm/610mm |

Weight Per Coil | 4-6tons |

Paint Brand | Beckers |

Paint Thickness | 15-25micron at top,5-10micron at reverse |

Zinc coating | 40-275g/m2 |

Standard | ASTM A755M/JIS G3312 |

Steel grade | CGCC |

Usage | home appliance,building materials,roof system,etc. |

MOQ | 25 tons |

Quality | approved by SGS |

Productivity | 100,000 Metric ton / year |

Key to success | advanced technique and good service and low price |

Authentification | ISO9001:2008 |

Market | North/South America, Europe, Asia,Africa,Mid East,ect. |

Packaging | wrapped by plastic film and waterproof paper, and then fastened on wooden pallet.Or according to clients' requirement. |

Port | Shanghai or Ningbo |

Delivery term | FOB / CIF/ CFR |

Delivery time | In 20-25 days after receipt of deposit or L/C |

Payment term | 30%T/T down payment,balance before shipment or irrevocable L/C at sight |

- Q: I'm not really sure if carbon steel is considered a metallic material.

- Steel with a lower to medium level of carbon will typically be reserved for metal sheeting for use in construction, due to its increased hardness and malleability.

- Q: What are the common methods of joining steel coils together?

- The common methods of joining steel coils together include welding, mechanical fastening (such as using bolts or screws), and adhesive bonding.

- Q: What are the dimensions of steel coils used in the electrical equipment industry?

- The dimensions of steel coils utilized in the electrical equipment industry may differ based on the particular application and requirements of the equipment being produced. However, there are certain dimensions that are commonly employed in this industry. Typically, the width of steel coils employed in the manufacturing of electrical equipment ranges from 0.5 inches to 72 inches (1.27 cm to 182.88 cm). The thickness of these coils can vary from extremely thin, measuring 0.005 inches (0.0127 cm), to considerably thick, measuring 0.25 inches (0.635 cm). The length of steel coils employed in the electrical equipment industry can also vary, but it is often determined by the production process and the specific equipment being manufactured. Coils can range in length from a few feet to several hundred feet. Moreover, the weight of steel coils can differ based on their dimensions and the type of steel being utilized. For example, a common weight range for steel coils employed in the electrical equipment industry falls between 5,000 pounds (2,268 kg) and 50,000 pounds (22,680 kg). It should be noted that these dimensions are not fixed and can vary depending on the specific requirements of the electrical equipment industry. Manufacturers may have their own distinct specifications and requirements for the steel coils they utilize in their products.

- Q: I have hundreds of pounds of scrap steel... who purchases this steel and what is the price per pound etc. of this? Does someone pick it up or do I bring it somewhere?

- Right now, steel is worth $150/ton. Who purchase it? Well, not every scrap yard handle steel, you have to call them up, or look at the company name that has the word steel or iron. But price can vary from each scrap yard. Try to call around. As for someone to pick it up, the scrap yard will mostly charge you a trucking fee and then the price for steel would be lower. But here is another bad thing if you have it pick up. I know some scrap yard are bad...reall bad..they will skim off some weight...a 1k lbs to 2k lbs. Wish you good luck!

- Q: How are steel coils used in the manufacturing of automotive fenders?

- Steel coils are used in the manufacturing of automotive fenders by being processed and shaped into the desired fender shape. The coils are first uncoiled and then sent through a series of machines that cut and shape the steel into the specific dimensions and contours required for the fender design. These shaped steel pieces are then welded or bolted together to form the final fender structure, which is later painted and installed onto the vehicle.

- Q: I'v had 5 people at school say steel is stonger than Titanium and some(5) kids at school say titanium stronger then steel but i looked it up on the internet and i got soem web sites that say steel is stronger then titanium and some sites that say titanium is stonger then steel sooooo???? witch one is strongerPS i no tungsten is stronger then steel.... and titanium.................

- Titanium has better high temperature strength than steel. Titanium doesn't resist shocks like steel can. It's more brittle. It's also far more difficult to weld. Titanium must be welded in an oxygenless environment. The average strength of steels that are made is under that of titanium. However, the strongest steel is stronger than the strongest titanium. Steel is the only viable building material. Titanium is too rare, expensive, and hard to handle for structures of great height. Hope this helps. Peace and Love.

- Q: Steel Strings on your guitar or nylons? Why?

- There is no OR about it. You CANNOT use steel strings on a nylon string guitar because the increased tension will actually warp the top of the guitar and eventually pull the bridge right off! (I have seen it happen several times!) Although it is possible to put nylon strings on a steel string guitar it is not recommended. Nylon strings do not have as much tension as a steel string guitar is designed for. Steel string guitar necks are actually designed with a bit of back bow to compensate for the high tension of steel strings. Nylon strings have a much lower tension which could cause the neck of a steel string to settle slightly, which could actually cause the strings to fret out. It is not common, but it does happen. So keep your guitars happy and only string them with the proper strings.

- Q: What are the different types of steel coil surface protection methods?

- There are several types of steel coil surface protection methods, including oiling, painting, galvanizing, and polymer coating. Oiling involves applying a thin layer of oil to prevent corrosion and rust. Painting involves using a protective paint coating to provide a barrier against moisture and other corrosive elements. Galvanizing involves coating the steel coil with a layer of zinc to provide corrosion resistance. Polymer coating involves applying a protective polymer film to prevent corrosion and improve durability.

- Q: How are steel coils inspected?

- Steel coils are inspected through various methods such as visual inspection, dimensional measurement, and non-destructive testing techniques. Visual inspection involves the examination of the coils for any surface defects, such as scratches, dents, or rust. Dimensional measurement ensures that the coils meet the required specifications in terms of thickness, width, and diameter. Non-destructive testing techniques like ultrasonic testing, magnetic particle inspection, and eddy current testing are used to detect any internal defects or discontinuities in the steel coils without causing any damage to the material. These comprehensive inspection methods ensure the quality and integrity of steel coils before they are used in various industries.

- Q: What are the environmental and social impacts of mining, processing and using steel?

- I don't think society as we know it could exist without it. As for the enviroment there is damage from mining, processing and from using steel equiptment.

Send your message to us

JIS G3312/ASTM A755 Prepainted Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords