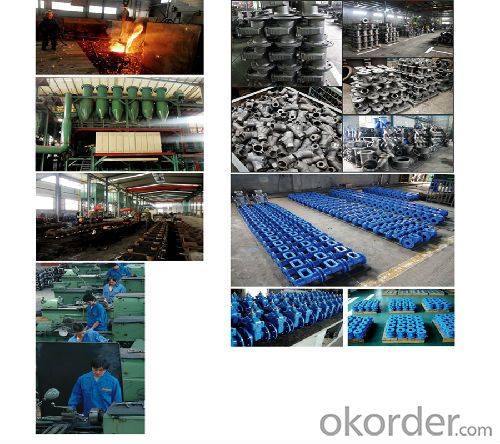

Iron Check Valve DN80 High Quality Hot sell

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 set

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Sizes: DN100 - DN800

Pressure: 1.6 - 6.4MPa

Suitable temperature: <80 C

Connection: RF

Constant Head Check Valve

Sizes: 4“ - 48"

Pressure: 1.6 - 6.4MPa

Suitable temperature: <80°C

Connection: RF

| aterial list(CN standard): | |||||

| NO. | Part Name | Carbon Steel Series | Stainless Steel Series | Alloy Steel Series | Low-temperature Steel Series |

| 1 | Body | WCB | CF8 | WC6 | LCB |

| 2 | DISC | WCB | CF8 | WC6 | LCB |

| 3 | Washer | Flexible graphite+ss304 | Flexible graphite+ss304 | Flexible graphite+ss304 | Flexible graphite+ss304 |

| 4 | Bonnet | WCB | CF8 | WC6 | LCB |

| 5 | Studs | 35CrMoA | 0Cr18Ni9(304) | 35CrMoA | 0Cr18Ni9(304) |

| 6 | Nut | 35# | 0Cr18Ni9(304) | 35CrMoA | 0Cr18Ni9(304) |

| 7 | Spring | 60Si2Mn | 0Cr18Ni9(304) | 0Cr18Ni9(304) | 0Cr18Ni9(304) |

| Technical Specification: | |||||||

| Design Standard | GB/T 12235 | ||||||

| Temperature Pressure Rating | GB/T 12224 | ||||||

| Structural Length | Factory Standard | ||||||

| Flange Dimensions | GB/T 9113,GB/T 79 | ||||||

| Inspection and Test | JB/T 9092,GB/T 13927 | ||||||

| nominal pressure | PN1.6 | PN2.5 | PN4.0 | PN6.4 | PN10.0 | PN16.0 | |

| Test Pressure(Mpa) | Body Test | 2.4 | 3.75 | 6.0 | 9.6 | 15.0 | 24.0 |

| High Pressure Seal | 1.76 | 2.75 | 4.4 | 7.04 | 11.0 | 17.6 | |

| Low Pressure Seal | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | |

| Applicable temperature | -196°C~550°C(Differeent temperature use different material) | ||||||

| Applicable Medium | water,gas,oil and corrosive media(different media use different material) | ||||||

| Quick Details | |||||

| Standard or Nonstandard: | Standard | Structure: | Check | Pressure: | Medium Pressure |

| Power: | Hydraulic | Material: | Carbon Steel, Stainless Steel | Temperature of Media: | Medium Temperature |

| Media: | Water, Oil, Gas etc. | Port Size: | DN250 | Place of Origin: | Hebei, China (Mainland) |

| Model Number: | OEM | Brand Name: | cmax | Application: | General |

| Name: | Check Valve | Type: | Lift Check Valve | Nominal Diameter: | DN15~900,NPS 1/4 ~36 |

| Nominal Pressure: | PN1.0-16.0MPa,ANSI CLASS 150-900,JIS10-20K | Connection Type: | Flange, butt welding, thread, socket welding, the clamp, etc | Working Temperature: | -196℃~540℃ |

| Valve Body Material: | WCB,CF8(304),CF3(304L),CF8M(316),CF3M(316L), | Applicable Medium: | Water, Oil, Gas etc | Model: | OEM |

| Certificate: | ISO9001, ISO4001 |

Application

Petroleum, chemical industry, pharmacy, fertilizer, power industry etc.

Advantage

1.Lift check valve is self-sealing valve. The disc can be acted by the flow which can protect against the media flow back.

2.The disc with spring can keep the valve work in any direction.

3.Reasonable structure, reliable sealing, excellent performance and attractive appearance make a TKFM valve.

- Q: Can the flue check valve and kitchen check valve protect against odor?

- Not really. It depends on what valve it is. If it is a variable pressure air valve, of course, if it is an ordinary other valves, generally only temporary role. Five residential home kitchen platoon smoke system is the application of this variable pressure air valve.

- Q: Can the check valve be used on the steam pipe?

- The check valve can be used on the steam pipe, but only the right material.General steam pressure WCB, temperature and pressure with the then high chromium molybdenum steel. The inside of the valve should be taken into account, depending on the pressure difference.

- Q: What is the difference between the silent check valve and the silent check valve?

- DRVZ according to the outline of the design of hydraulics has streamlined waterway better, with the design of internal guide fluid to ensure minimal pressure loss, silent check valve in water backflow before quickly shut down to avoid water hammer, water hammer sound and destructive impact to mute.

- Q: What's the difference between the cut-off, check, check, and stop valves three? Better picture,

- Stop check valve: when the handwheel is rotated so that the valve stem rises, the disc does not rise together, but only the valve clack is released.

- Q: What is the difference in price between the check valve HH48X-10C and the HH49X-10C?

- HH47X, HH48X and HH49X are all the same, all of which are micro blocking, slow closing and butterfly type silencing check valves.

- Q: Ball shaped sewage check valve pictures and working principle of the structure.

- Check valve refers to rely on the flow of the media itself and automatically open and close the valve flap, used to prevent media backflow valve, also known as check valve, one-way valve, counter flow valve, and back pressure valve. The check valve belongs to an automatic valve, whose main function is to prevent the backflow of medium, prevent the reverse of pump and drive motor, and release the container medium.

- Q: Our unit pump outlet check valve installed in the vertical pipe, the use of the valve to stop the valve is more serious impact, is not installed, the valve should be how to install it?

- Check valves shall be installed on the vertical pipe. Select a model, such as a slow closing check valve (water hammer) or a spring check valve.

- Q: What does the check valve h44t-16 mean?

- Flanged swing check valve [H stands for check valve, 4 represents flange, 4 represents structural form (swing type), T represents internal copper alloy, and 16 represents pressure 16 pressure. I hope it will help you

- Q: Is the check valve a check valve? What is its main purpose?

- Check valve, also known as one-way valve or check valve, its role is to prevent the medium back in the pipeline.

- Q: What does the check valve "H64" and "H14" mean?

- H check valve6 welding connection1 threaded connection4 swing check valveJB/T308-2004< valve type programming method >There should also be sealing surface material code and nominal pressure level

Send your message to us

Iron Check Valve DN80 High Quality Hot sell

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 set

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords