Insulating Fire Brick - Lightweight for Steel Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

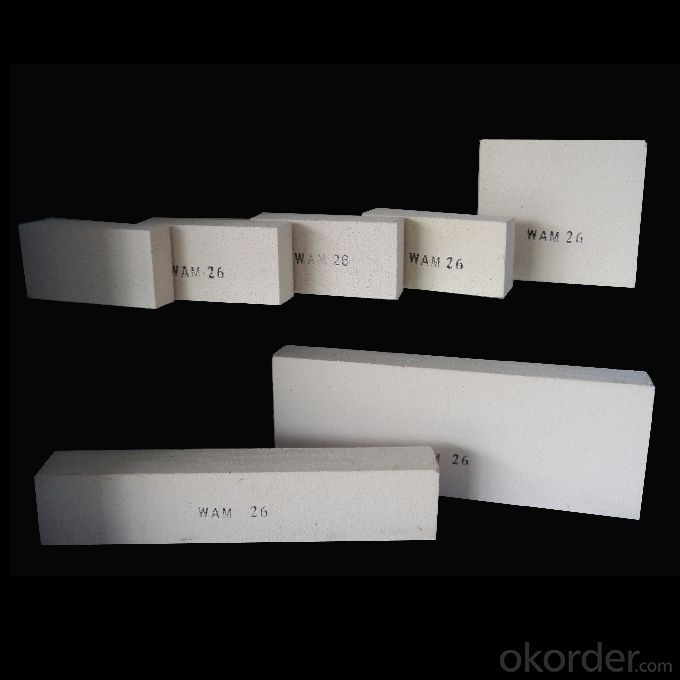

Insulating Fire Brick with Light Weight are high performance insulation products manufactured with unique shot removing and vacuum forming process, provide excellent high temperature stability, extra low thermal conductivity and compressive strength.

Advantages of Insulating Fire Brick:

Low thermal conductivity.

High strength and resistance to corrosion.

Low heat capacity.

Low shrinkage after heavy firing.

High insulation

High refractoriness.

Low density.

Applications:

Insulating Fire Brick is highly applied in below:

Steel furnaces

Iron making furnaces

Glass kiln

Ceramic tunnel kiln

Cement kiln

FAQ:

Payment term:T/T 30 deposit after order confirmed,the balance after goods ready before shipping,or L/C, or Western Uninon for small amount.

Lead time:Normally in 5-10 days after deposit received

Sample apolicy:Sample are always available for each modle

Shipping port: Tianjing

Technical Data Sheet:

Item | Insulating Fire Brick with Light Weight | |||

0.6 | 0.8 | 1.0 | 1.3 | |

Al2O3 (%) | 40 | 40 | 40 | 40 |

Fe2O3 (%) | 1.5 | 1.5 | 1.2 | 2 |

SiO2 | 55 | 55 | 55 | 55 |

Bulk Density (g/cm3) | 0.6 | 0.8 | 1.0 | 1.2 |

Apparent Porosity % | 70 | 60 | 55 | 50 |

Cold Crushing Strength (Mpa) ≥ | 2.0 | 2.5 | 3.0 | 4.0 |

Reheating Linear Change (%)°C X 12H ≤ | 1300℃ -0.5 | 1350℃ -0.5 | 1350℃ -0.9 | 1350℃ -0.9 |

Thermal Conductivity((W/m.k)(1000°C) | 0.33 | 0.60 | 0.45 | 0.80 |

Max Service Temperature (°C) | 1200 | 1280 | 100 | 1350 |

- Q: Do insulating fire bricks have a high resistance to spalling?

- Yes, insulating fire bricks have a high resistance to spalling.

- Q: Can insulating fire bricks be used in kiln car construction?

- Insulating fire bricks, which are manufactured using lightweight materials like ceramic fibers or lightweight refractory aggregates, can be utilized in the construction of kiln cars. These bricks possess exceptional insulating properties and have a low thermal conductivity, enabling them to effectively retain heat and prevent heat transfer to the outer surface of the kiln car. Incorporating insulating fire bricks into kiln car construction offers numerous advantages. Firstly, it aids in reducing heat loss, thereby enhancing energy efficiency and reducing fuel consumption. This benefit is especially significant in high-temperature applications such as kilns, where maintaining a consistent temperature is of utmost importance. Secondly, the utilization of insulating fire bricks helps safeguard the kiln car from thermal stresses and cracking. Due to the firing cycles, kilns experience substantial temperature fluctuations, and the presence of insulating fire bricks minimizes thermal shock, consequently prolonging the lifespan of the kiln car. Additionally, insulating fire bricks are notably lighter compared to conventional refractory bricks, making them more manageable and easier to install during kiln car construction. This, in turn, can result in cost savings related to labor and transportation expenses. However, it is crucial to note that insulating fire bricks possess lower strength and durability when compared to denser refractory bricks. Therefore, they are typically used in the hot face lining of kilns, while a more robust material is employed for the kiln car structure. In summary, the effective utilization of insulating fire bricks in kiln car construction can yield benefits such as improved energy efficiency, protection against thermal stresses, and overall enhancement of kiln performance.

- Q: Can insulating fire bricks be used in refractory coatings?

- Yes, insulating fire bricks can be used in refractory coatings. They provide excellent thermal insulation properties and can help in maintaining high temperatures while minimizing heat loss.

- Q: Are insulating fire bricks resistant to flame impingement?

- Yes, insulating fire bricks are resistant to flame impingement.

- Q: What is the recommended thickness of insulating fire bricks for optimal insulation?

- The recommended thickness of insulating fire bricks for optimal insulation can vary depending on the specific application and desired level of thermal protection. However, in general, insulating fire bricks with a thickness ranging from 2.5 to 4 inches (6.35 to 10.16 cm) are commonly recommended for achieving efficient insulation. Insulating fire bricks are designed to have low thermal conductivity, which means they are able to effectively minimize heat transfer. The thicker the bricks, the higher the insulating properties as they provide a greater barrier against thermal energy loss or gain. This is particularly important in applications where maintaining a stable temperature is crucial, such as in industrial furnaces, kilns, or high-temperature appliances. It is important to consider the specific requirements of the insulation project and consult with experts or manufacturers to determine the most suitable thickness for the insulating fire bricks. Factors such as the maximum temperature, duration of exposure, and desired energy efficiency should be taken into account to ensure optimal insulation performance.

- Q: Can insulating fire bricks be used in the construction of aluminum smelting furnaces?

- Insulating fire bricks can indeed be utilized in the construction of aluminum smelting furnaces. These bricks are crafted from lightweight materials like refractory clay and possess exceptional insulating qualities. Consequently, they are well-suited for implementation in environments with elevated temperatures, such as aluminum smelting furnaces. By conserving heat and enhancing energy efficiency, they prove to be advantageous in these settings. Typically, aluminum smelting furnaces function at remarkably high temperatures, frequently exceeding 1000 degrees Celsius. In such extreme circumstances, insulating fire bricks serve as effective thermal insulation, thereby minimizing heat loss and sustaining the desired temperature inside the furnace. This insulation also contributes to reducing the energy required to heat the furnace, leading to cost savings and heightened efficiency. Furthermore, insulating fire bricks exhibit exceptional resistance to thermal shock. This quality enables them to endure rapid temperature variations without experiencing cracking or breakage. This characteristic holds significance in the context of an aluminum smelting furnace, where heating and cooling cycles can occur frequently and swiftly. In addition, insulating fire bricks possess low thermal conductivity, which is another advantage when employed in aluminum smelting furnaces. This property facilitates the retention of heat within the furnace, preventing it from dissipating into the surrounding environment. By diminishing heat loss, insulating fire bricks aid in maintaining a consistent temperature throughout the smelting process, ensuring optimal conditions for aluminum melting and refining. In summary, due to their remarkable insulating properties, resistance to thermal shock, and low thermal conductivity, insulating fire bricks constitute a suitable choice for constructing aluminum smelting furnaces. Their utilization contributes to enhanced energy efficiency, reduced heat loss, and the maintenance of a stable temperature inside the furnace.

- Q: Do insulating fire bricks have a low thermal expansion rate?

- Yes, insulating fire bricks typically have a low thermal expansion rate.

- Q: How do insulating fire bricks affect the overall indoor air quality of a building?

- Insulating fire bricks have a positive impact on the overall indoor air quality of a building. These bricks are designed to resist high temperatures and prevent heat transfer, which helps in maintaining a comfortable and consistent indoor temperature. By improving thermal insulation, they reduce the need for excessive use of heating and cooling systems, thereby minimizing the release of pollutants and improving energy efficiency. Additionally, insulating fire bricks are non-combustible, meaning they do not emit harmful gases or particulate matter when exposed to heat. This further contributes to a healthier indoor environment by reducing the potential for air pollution and respiratory issues.

- Q: Can insulating fire bricks be used in the construction of heat exchangers?

- Yes, insulating fire bricks can be used in the construction of heat exchangers. These bricks are designed to withstand high temperatures and have excellent insulating properties, making them suitable for heat exchanger applications where heat retention and insulation are important.

- Q: Are insulating fire bricks resistant to electrical conductivity?

- Insulating fire bricks exhibit resistance to electrical conductivity. Their composition comprises materials with low electrical conductivity, like ceramic fibers or insulating refractory materials. The primary objective of these fire bricks is to offer thermal insulation, rendering them suitable for situations that demand the containment of high temperatures. Due to their minimal electrical conductivity, insulating fire bricks serve as linings in electrical furnaces, kilns, and other high-temperature apparatuses that necessitate electrical insulation.

Send your message to us

Insulating Fire Brick - Lightweight for Steel Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords