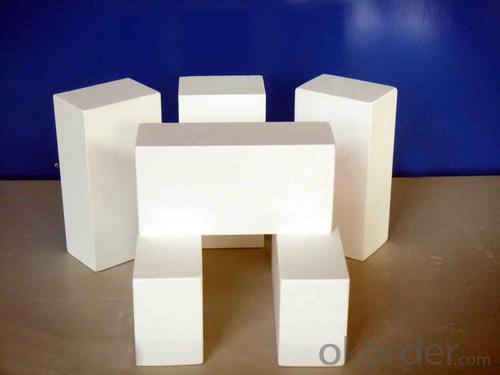

Insulating Fire Brick - High Temperature Bubble Alumina Brick

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Bubble Alumina Brick and Insulating Firebrick are high temperature refractory brick, max temp 1800 deg C, used in furnace kiln.

Bubble Alumina Brick and Insulating Firebrick are high temperature refractory brick.

Bubble Alumina Brick. We stock in both 2.5 & 3” sizes. We also carry double bump interlocking anchor styles. For use up to 1800C, these brick have excellent insulating properties as well as high hot strengths.

Insulating firebrick, we carry produces thirteen types of Insulating Fire Brick for use in applications from 2,000°F (1,093°C) to 3,200°F (1,760°C). Each type is formulated to meet specific thermal and physical requirements and after firing is machined to precise tolerances.

Made from high purity refractory clays and other ceramic raw materials, these insulating fire brick contain a carefully graded organic filler which is burned out during manufacture to give a uniform controlled pore structure.

Advantages of bubble alumina brick.

High Insulating Va

The high compressive strength of bubble alumina brick allows for self-supporting structures at elevated temperatures. Insulating fire brick are compatible with dense fire brick and add strength to the whole construction.

Low Heat Storage

Lower heat storage versus dense brick means reduced fuel costs in cyclically operated heating equipment. lue

The light weight and high insulating value of refractory brick make possible thinner furnace walls, improved efficiency and lower operating costs.

Strong

The high compressive strength of bubble alumina brick allows for self-supporting structures at elevated temperatures. Insulating fire brick are compatible with dense fire brick and add strength to the whole construction.

Low Heat Storage

Lower heat storage versus dense brick means reduced fuel costs in cyclically operated heating equipment.

Application

DJM 26 Light Weight Insulating fire brick are used for the lining of converter, alternating current arc furnace, direct Current arc furnace and the ladle slag line, etc.

Company Advantage

(1)Long Insulating Fire Brick manufacture history: 25 years manufacturer

(2)Advanced equipment

(3)Diversification of production standards: ISO ANSI FEPA JIS ASTM

Equipment

1 unit of Ceramic Abrasive (SG Abrasive) pilot production line

1 unit of high-end coated abrasives (abrasive cloth) production line

2 units of Boron Carbide production lines

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: Refractory bricks, burner bricks, insulation bricks? Is it a kind of thing?

- Not the same thing, refractory bricks and insulation bricks of raw materials, the proportion is not the same. This is the chain of various types of products

- Q: How do insulating fire bricks prevent heat transfer?

- Insulating fire bricks prevent heat transfer by their unique composition and structure. They are made of lightweight refractory materials that have low thermal conductivity. This means that they are poor conductors of heat, which helps to minimize the transfer of heat from one side of the brick to the other. Additionally, the bricks are designed with small air pockets or voids, which further reduces heat conduction by trapping air and preventing its movement. The combination of low thermal conductivity and trapped air pockets effectively hinders the transfer of heat, making insulating fire bricks an excellent choice for applications where heat insulation is required.

- Q: Are insulating fire bricks resistant to abrasion or wear?

- Yes, insulating fire bricks are resistant to abrasion or wear. These bricks are made from high-quality refractory materials, such as alumina or silica, which have excellent resistance to abrasion. The manufacturing process involves high-temperature firing, which strengthens the bricks and enhances their durability. Insulating fire bricks are specifically designed to withstand the harsh conditions of high-temperature applications, such as furnaces, kilns, and fireplaces. They are highly resistant to thermal shock, chemical erosion, and mechanical wear. This makes them a reliable choice for insulating and protecting the inner walls of these structures, ensuring long-lasting performance and minimizing the need for frequent replacements.

- Q: Can insulating fire bricks be recycled or reused?

- Yes, insulating fire bricks can be recycled or reused. Insulating fire bricks are made from various materials such as alumina, silica, and clay, which can be broken down and reused in the production of new bricks. Recycling these bricks involves crushing them into a fine powder and then mixing it with other raw materials to create new bricks. Reusing insulating fire bricks is also possible in certain applications. For example, if the bricks are still in good condition and have not been damaged, they can be removed from one structure and used in another. This reduces waste and saves resources. Overall, whether through recycling or reusing, insulating fire bricks can have a second life and contribute to a more sustainable and environmentally-friendly construction industry.

- Q: Can insulating fire bricks be used in the construction of lime calciners?

- Yes, insulating fire bricks can be used in the construction of lime calciners. Lime calciners require high temperatures to produce lime, and insulating fire bricks are designed to withstand and retain heat. These bricks have low thermal conductivity, allowing them to effectively insulate the calciner and prevent heat loss. Additionally, insulating fire bricks are lightweight, making them easier to handle and install in the construction of lime calciners.

- Q: Can insulating fire bricks be used in refractory castings?

- Yes, insulating fire bricks can be used in refractory castings. These bricks are designed to have low thermal conductivity, making them suitable for applications where high insulation is required, such as in refractory castings. They provide excellent heat insulation and can withstand high temperatures, making them an ideal choice for various refractory applications.

- Q: Are insulating fire bricks suitable for insulation in boilers for steam generation?

- Insulating fire bricks are a suitable choice for insulation in steam generation boilers. Specifically designed to possess exceptional thermal insulation properties, these bricks are perfect for high-temperature applications like boilers. With their low thermal conductivity, they effectively minimize heat transfer and prevent heat loss. This insulation capability aids in maintaining optimal temperatures within the boiler, thereby enhancing energy efficiency and reducing fuel consumption. Moreover, these bricks can withstand thermal shock, making them highly resistant to the extreme temperature fluctuations encountered during steam generation. Overall, incorporating insulating fire bricks into steam generation boilers can significantly improve the system's thermal efficiency and performance.

- Q: Can insulating fire bricks be used in refractory linings for blast furnaces?

- Yes, refractory linings for blast furnaces can utilize insulating fire bricks. These bricks are specifically designed to possess low thermal conductivity, effectively minimizing heat loss from the furnace. This characteristic holds particular significance in blast furnaces where maintaining high temperatures is crucial for optimal operation. Insulating fire bricks are crafted from lightweight refractory materials like alumina or silica, renowned for their exceptional insulating properties. These bricks not only provide thermal insulation, but they also exhibit remarkable resistance to thermal shock, rendering them suitable for the extreme conditions prevalent in blast furnaces. Beyond insulation, insulating fire bricks present additional advantages for blast furnace linings. They possess a lightweight nature and are easily installable, thereby reducing construction labor and time requirements. Moreover, their low thermal conductivity aids in minimizing the occurrence of hot spots and uneven temperature distribution within the furnace. These issues, if unaddressed, can trigger premature wear and failure of the refractory lining. However, it is crucial to acknowledge that relying solely on insulating fire bricks may not suffice for all portions of the blast furnace lining. Certain areas, such as the hearth and tuyere zones, may necessitate high-density refractory bricks capable of withstanding intense heat and mechanical stress. In such cases, a combination of insulating fire bricks and other refractory materials can be employed to achieve the desired performance and longevity. Overall, insulating fire bricks serve as a valuable constituent in refractory linings for blast furnaces, offering benefits such as enhanced energy efficiency, reduced heat loss, and prolonged lifespan of the lining.

- Q: Are insulating fire bricks resistant to vermin infestation?

- Yes, insulating fire bricks are typically resistant to vermin infestation. These bricks are made from materials such as ceramic fibers, which do not provide a suitable environment for pests to inhabit or cause damage. Additionally, their dense composition and high-temperature resistance make it difficult for vermin to penetrate or chew through them.

- Q: Can insulating fire bricks be used in the construction of smelting furnaces?

- Yes, insulating fire bricks can be used in the construction of smelting furnaces. Insulating fire bricks are designed to withstand high temperatures and provide excellent insulation, making them ideal for smelting furnaces. These bricks have low thermal conductivity, which helps to minimize heat loss and maintain a consistent temperature inside the furnace. Additionally, insulating fire bricks are lightweight, making them easier to handle and install. Overall, the use of insulating fire bricks in smelting furnace construction can improve energy efficiency, reduce operating costs, and enhance the overall performance of the furnace.

Send your message to us

Insulating Fire Brick - High Temperature Bubble Alumina Brick

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords