I Beam Steel YBT24 for Mining Applications with Large Sizes

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of I Beam Steel YBT24 for Mining Applications with Large Sizes Description:

I beam steel YBT24 for mining applications with large sizes is a beam with an I-shaped cross-section. The horizontal elements of the "I" are known as flanges, while the vertical element is termed the "web". I beam steel YBT24 for mining applications with large sizes is usually made of structural steel and is used in construction and civil engineering. The I beam steel YBT24 for mining applications with large sizes resists shear forces, while the flanges resist most of the bending moment experienced by the beam. I beam steel YBT24 for mining applications with large sizes theory shows that the I-shaped section is a very efficient form for carrying both bending and shears loads in the plane of the web.

2. Main Features of I Beam Steel YBT24 for Mining Applications with Large Sizes:

• Grade: Q235

• Type: Mild carbon steel

• Deflection: The stiffness of the I-beam will be chosen to minimize deformation

• Vibration: The stiffness and mass are chosen to prevent unacceptable vibrations, particularly in settings sensitive to vibrations, such as offices and libraries.

• Local yield: Caused by concentrated loads, such as at the beam's point of support.

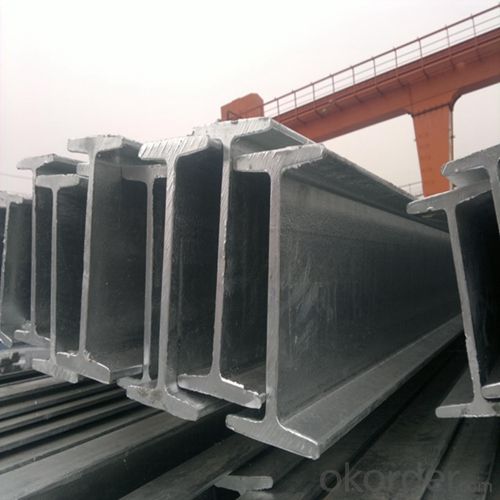

3. I Beam Steel YBT24 for Mining Applications with Large Sizes Images:

4. I Beam Steel YBT24 for Mining Applications with Large Sizes Specification:

Mechanical Properties | Grade | Steel diameter(mm) | |||

≤16 | 16~40 | 40~60 | 60~100 | ||

Yield Point Δs/MPa | Q195 | ≥195 | ≥185 | - | - |

Q235 | 235 | 225 | 215 | 205 | |

Tensile Strength | Q195 | 315~390 | |||

Q235 | 375~500 | ||||

Elongation δ5% | Q195 | ≥33 | ≥32 | - | - |

Q235 | 26 | 25 | 24 | 23 | |

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①Is this product same as W beam?

In the United States, the most commonly mentioned I-beam is the wide-flange (W) shape. These beams have flanges in which the planes are nearly parallel. Other I-beams include American Standard (designated S) shapes, in which flange surfaces are not parallel, and H-piles (designated HP), which are typically used as pile foundations. Wide-flange shapes are available in grade ASTM A992,[4] which has generally replaced the older ASTM grades A572 and A36.

②How to inspect the quality?

We have a professional inspection group which belongs to our company. We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③Is there any advantage about this kind of product?

Steel I beam bar IPE has a reduced capacity in the transverse direction, and is also inefficient in carrying torsion, for which hollow structural sections are often preferred.

- Q: Can steel I-beams be used for solar panel supports?

- Yes, steel I-beams can be used as supports for solar panels. Steel I-beams are commonly used in construction for their strength and durability, making them suitable for supporting the weight of solar panels. Additionally, steel is resistant to weathering and provides stability, ensuring the panels remain securely mounted.

- Q: How are steel I-beams used in commercial construction?

- Steel I-beams are commonly used in commercial construction as structural support elements. These beams are designed to withstand heavy loads and provide stability to the building. They are often used as columns, beams, and framework in the construction of high-rise buildings, warehouses, bridges, and other large-scale structures. The I-shape of the beam helps distribute the weight evenly, making it a reliable choice for supporting heavy loads over long spans.

- Q: What are the typical costs associated with steel I-beams?

- The cost of steel I-beams can differ based on various factors. The beam's size and weight are crucial in determining its cost. Generally, larger and heavier beams are pricier than smaller ones. The grade of steel used is another factor that impacts the cost. Different grades have varying levels of strength and durability, resulting in different price points. Higher-grade steel is typically more expensive than lower-grade options. Moreover, the beam's length influences the cost. Longer beams require more material and may need specialized transportation, increasing the overall price. Considering the quantity required is also important. Ordering a larger quantity of steel I-beams may lead to volume discounts, reducing the cost per unit. Additionally, market conditions and the supplier's location can influence the cost. Regional price variations occur due to factors like supply and demand, transportation costs, and local competition. For precise cost information on steel I-beams, it is advisable to contact suppliers or refer to pricing guides specific to the steel industry.

- Q: Can steel I-beams be used as columns or posts in construction?

- Yes, steel I-beams can be used as columns or posts in construction. They are commonly used in structural applications where strength and durability are required. I-beams provide excellent load-bearing capacity and are often preferred for their ability to support heavy loads and resist bending or buckling.

- Q: What are the factors to consider when designing connections for steel I-beams?

- To achieve structural integrity and overall safety in steel I-beam connections, several factors must be considered. Here are some key considerations: 1. Load and stress analysis: Thoroughly examining the loads and stresses the I-beams will endure is crucial. This involves evaluating both static and dynamic loads, as well as potential future additional loads. The connection design should efficiently distribute these loads and stresses across the beams and connecting elements. 2. Connection type selection: Different connection types, such as bolted, welded, or a combination of both, are available for steel I-beams. Each type has its own advantages and limitations. Choosing the appropriate connection type should be based on load requirements, ease of installation, accessibility, and potential for future modifications or disassembly. 3. Compatibility with the surrounding structure: The connection design must be compatible with the overall structural system and existing connections. It should not cause conflicts or detrimental effects on surrounding elements or compromise the structure's performance. 4. Connection strength and rigidity: The connection design should provide sufficient strength and rigidity to resist applied loads and prevent excessive deflection or deformation. This requires considering the capacity of connected elements and ensuring the connection can transfer loads without failure or excessive movement. 5. Material compatibility: The materials used for connection elements (bolts, welds, or plates) should be compatible with the steel I-beams and possess similar mechanical properties. This ensures effective load transfer and the ability to withstand potential forces or deformations. 6. Fabrication and installation feasibility: The connection design should be practical and feasible for cost-effective and timely fabrication and installation. Factors like ease of access, standardization of connection details, and the availability of skilled labor or equipment for fabrication and installation must be considered. 7. Maintenance and future modifications: Ease of maintenance and potential future modifications to the connection should be considered. This includes providing access for inspection, repair, or component replacement, as well as accommodating changes or additions to the structure. By considering these factors, engineers can design connections for steel I-beams that meet performance criteria and ensure long-term durability and safety of the structure.

- Q: What are the common finishes available for steel I-beams?

- Steel I-beams can be finished in various ways, depending on the desired outcome and purpose. One option is to leave the steel in its raw state, known as a mill finish. This finish is commonly used for structural applications where aesthetics are not a priority. Another choice is to apply a painted or powder-coated finish to the I-beam. This involves adding a layer of paint or powder coating to enhance the appearance and provide protection against rust and corrosion. These finishes can be customized to match specific color requirements or provide extra durability. Hot-dip galvanizing is a popular finish for steel I-beams. This process involves immersing the I-beam in molten zinc, creating a protective layer that offers excellent resistance to corrosion. Galvanization can significantly extend the lifespan of the I-beam, making it ideal for harsh environments. Lastly, stainless steel I-beams can be finished with a brushed or polished look. This finish not only enhances the steel's aesthetic appeal but also provides some level of resistance against corrosion. Stainless steel I-beams are often chosen for architectural and decorative purposes where appearance is crucial. Ultimately, the choice of finish for steel I-beams depends on factors such as the specific application, budget, and desired aesthetics. It is essential to consider aspects like corrosion resistance, durability, and appearance when selecting the appropriate finish for steel I-beams.

- Q: How do steel I-beams contribute to the overall architectural design of a structure?

- Steel I-beams are a crucial element in the overall architectural design of a structure due to their exceptional strength, versatility, and load-bearing capabilities. These beams, which form the framework of the building, play a significant role in distributing the weight and forces exerted on the structure, thus ensuring its stability and integrity. One of the primary contributions of steel I-beams to architectural design is their ability to span long distances without the need for excessive support columns or walls. This allows for open and flexible floor plans, creating vast and unobstructed spaces. By minimizing the need for interior load-bearing walls, architects have more freedom in designing the layout, facilitating creative and functional spaces that meet the specific needs of the occupants. Moreover, steel I-beams provide structural support for multi-story buildings, enabling architects to design taller structures with greater height and verticality. This is particularly advantageous in urban environments where space is limited, as it allows for the efficient use of available land by constructing upward. The strength and rigidity of steel I-beams make it possible to build skyscrapers and high-rise buildings that can withstand the various forces, such as wind and seismic loads, that act upon them. In addition to their structural functionality, steel I-beams also contribute to the aesthetic appeal of a structure. Their sleek and minimalistic design adds a modern and industrial touch to the architectural style, which is highly sought after in contemporary design. The clean lines and open spaces created by I-beams can be used to emphasize architectural features, showcase expansive views, or create dramatic visual effects. Furthermore, steel I-beams are versatile in their application, allowing architects to incorporate them into various design elements. They can be exposed and left visible, becoming an integral part of the building's aesthetic. Alternatively, they can be concealed within walls, floors, or ceilings, providing a hidden structural support system that maintains the design integrity while maximizing usable space. Overall, steel I-beams are an essential component of architectural design, contributing to the overall strength, flexibility, and aesthetic appeal of a structure. Their ability to bear heavy loads, span long distances, and create open and unobstructed spaces make them a preferred choice for architects aiming to achieve both structural and design excellence in their projects.

- Q: Are there any health and safety considerations when working with steel I-beams?

- When working with steel I-beams, there are multiple health and safety considerations to take into account. These considerations encompass the following: 1. Personal Protective Equipment (PPE): To safeguard against potential dangers such as falling objects, cuts, and impacts, workers must consistently wear suitable PPE including safety glasses, steel-toed boots, gloves, and hard hats. 2. Manual Handling: Proper lifting techniques are necessary to prevent strains, sprains, or other musculoskeletal injuries caused by the weight of steel I-beams. Workers should undergo adequate training on safe lifting and moving methods, and whenever possible, mechanical lifting aids should be utilized. 3. Structural Stability: Prior to commencing work with steel I-beams, it is crucial to verify the stability and capacity of the supporting structure to prevent collapse or structural failures. Structural engineers should assess the integrity of the structure to ensure it can withstand the weight of the beams and the workers. 4. Falls from Heights: Given that working with steel I-beams often involves tasks performed at elevated positions during installation or maintenance, measures for fall protection such as guardrails, safety nets, or personal fall arrest systems must be in place. These precautions are vital to prevent falls and safeguard workers against severe injuries. 5. Welding and Cutting Hazards: The fabrication or modification of steel I-beams may necessitate welding or cutting processes that produce hazardous fumes, sparks, and intense heat. To minimize risks associated with these operations, adequate ventilation, fire prevention measures, and comprehensive training in welding and cutting techniques are imperative. 6. Hazardous Materials: Certain steel I-beams may be coated with paints, coatings, or preservatives containing hazardous substances like lead or asbestos. Workers should be aware of these potential hazards and follow proper safety procedures, such as utilizing respiratory protection and employing appropriate handling techniques, to prevent exposure. In summary, working with steel I-beams necessitates strict adherence to safety protocols in order to protect workers from various hazards arising from the weight, structural integrity, height, welding processes, and potential exposure to hazardous materials.

- Q: Can steel I-beams be used in residential renovations or additions?

- Absolutely, steel I-beams are certainly viable for residential renovations or additions. In truth, they are frequently the favored option for providing structural support in such endeavors. Renowned for their robustness and endurance, steel I-beams are ideally suited for bearing substantial loads and ensuring stability throughout the entire structure. They can bolster existing walls, floors, or roofs, or be seamlessly integrated into new construction, allowing for expansive floor plans and broad spans. Moreover, steel I-beams are remarkably adaptable and can be effortlessly tailored to suit the precise demands of any given project. Nonetheless, it is imperative to consult a structural engineer or professional contractor to guarantee the proper design and installation of steel I-beams that cater to the unique requirements of the residential renovation or addition.

- Q: What are the different types of steel coatings used for I-beams?

- There are several different types of steel coatings that are commonly used for I-beams. These coatings are applied to the steel to provide protection against corrosion and enhance the durability and longevity of the beams. One of the most common types of steel coating used for I-beams is hot-dip galvanizing. This involves dipping the beams in a bath of molten zinc, which forms a protective layer on the surface of the steel. Hot-dip galvanizing provides excellent corrosion resistance and is particularly well-suited for outdoor applications or environments with high levels of moisture. Another type of steel coating used for I-beams is epoxy coating. This involves applying a layer of epoxy paint to the surface of the beams. Epoxy coatings provide a strong barrier against corrosion and can be customized to meet specific requirements, such as high chemical resistance or fire resistance. Zinc-rich paint coatings are also commonly used for I-beams. These coatings contain a high concentration of zinc particles, which provide cathodic protection to the steel. The zinc particles act as sacrificial anodes, corroding in place of the steel and extending its lifespan. In addition to these coatings, there are also thermal spray coatings, such as metallizing or flame spraying, which involve applying a layer of molten metal onto the surface of the beams. These coatings provide excellent protection against corrosion and can be tailored to meet specific performance requirements. Overall, the choice of steel coating for I-beams will depend on factors such as the desired level of corrosion resistance, the environmental conditions the beams will be exposed to, and any specific performance requirements. It is important to consult with a professional coating specialist to determine the most suitable coating for a particular application.

Send your message to us

I Beam Steel YBT24 for Mining Applications with Large Sizes

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords