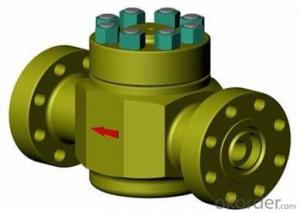

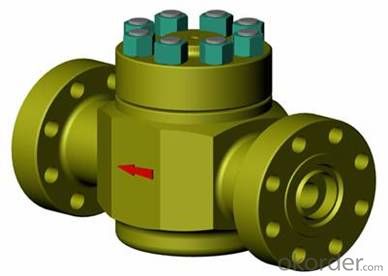

Hydraulic plate valve with high quality and best price from okorder.com

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

| Place of Origin: | China (Mainland) | Model Number: | Hydraulic plate valve | Brand Name: | OKORDER |

| Type: | Rotary Drilling Rig | Certification: | API | Usage: | Oil Well |

| Condition: | New | Warranty: | 1 | Voltage: | 2,000-15000 psi |

Specifications

Hydraulic plate valve

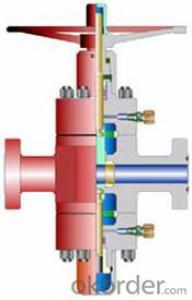

SS Gate Valve Handwheel Operated

1.Medium: water, oil, gas.

2.Certificate:API 6D,TS,CE.

Hydraulic plate valve

Applicable standards:Steel gate valves, API 600 / API 6D

Steel gate valves, ISO 10434 / ISO 14313

Steel valves, ASME B16.34

Face to face, ASME B16.10

Flanges end, ASME B16.5

Buttwelding ends, ASME B16.25

Inspection and test, API 598 / API 6D

Design description:

Full port design

OS&y,outside screw and yoke

BB,Bolted bonnet

Flexible wedge,fully guided

Choice of solid or split wedge

Renewable seat rings

Forged T-head Stem

Rising stem and non-rising handwheel

Flanged or buttwelding ends

Available with BG operator

Gate Valve Product Details

Design and Manufacture | ANSI B16.34,API600,API603,BS1414 |

Face to face(end to end) | ANSI B16.10,API6D |

Flanged connection | 2"~24" TO ANSIB16.5,22",26"~36" TO MSS-SP-44 to API 605 on Request |

Test and inspection | API 598,API6D |

Butt welded end | ANSI B16.5 |

A. Anti-friction ball thrust bearing: Reduces friction between mating parts to ensure smooth operation

B. Grub screw: Secures yoke nut in the bonnet

C. Grease nipple: Supplies lubricant to the mating parts

- Q: We have an oil steam system. There are Dole valves - 1A on each of the radiators. We bought new ones. They don't seem to be working. They look like a bullet shape with a screw in (on the side of the bullet) to the radiator. On the top of the bullet is a slit with numbers 1-10 on a dial. A picture we saw on the web showed a plastic piece of tubing in the screw part which looks like it goes into the radiator. If we remove the valve, the radiator gets hot with steam coming out of the hole. With the new valve on, the radiator barely gets warm. We're in Piscataway, NJ 08854. H-E-L-P.

- Seems to me that a steam valve would need to hold a lot more pressure than a hot water valve. Steam is a high pressure gas and water is a liquid irregardless how hot it is (below boiling point) I am not a qualified plumber or boiler tech but personally I wouldn't use a steam valve for water or vise versa.

- Q: I was considering making a ball valve PVC air rifle or something of the sort using a PVC air canister and a hand pump, but I wanted to know about it, last year I made one that was air tight but air leaked out of the top of the pump which really annoyed me, I looked further onto the it and found out that there was a Bike Tyre valve, What does it do? Does it let air flow in but stop it from coming out? and where would I find some good designs as well as the items needed to make it? And don't bother answering 'Buy an air soft gun' because Australia does not retail those.

- hi there in canada , at any big truck tire repair place they have tire valves that are like bunker fittings, that is to say a valve that has a threaded bottom end with nuts and rubber washers, you would drill the appropriate size hole in the pipe and put the valve through and tighten the nuts up against the washers making an air tight seal, that should work for you if they have them in au, good luck

- Q: The pump is working fine on the presta valve on my back tire, but it is not working on the other presta valve. It seems like the the presta valve isn't sticking out far enough out of the tube for the pump to be able to lock in on it. What could be causing this?

- to apply the adapter, you need to first unscrew the presta valve, then placed the adapter on and pump up the tire, then take the adapter off and tighten the presta valve to close it. I consider the different answer that that's recommended to replace the tubes so as that the presta valve does not come aside. New tubes are inexpensive - approximately $6 or so. you need to purchase a spare, too, merely in case you flat. in case you do no longer understand the thank you to alter the tubes, your community motorbike save can do this for you and clarify the technique so as which you're able to do it your self interior the destiny and sell you the tire levers (and patch kit in case you want) you will ought to do it. reliable success!

- Q: Hello,I've not found a perfect fit using a solenoid valve for gravity fed irrigation system. Primarily because it requires a constant drain on the battery while the valve is open. Is there a motorized valve to fit the bill? One that momentarily requires electricity to open and close the valve at 12v DC or less to work in gravity fed system?

- I don't know how it specifically wires. There are two strategies for latching devices. One is a solenoid with two coils. Pulse one to open, pulse the other to close. The other strategy is to have one coil. Apply polarity in one direction to open, in the other to close. I suggest googling for latching solenoid valve, and/or checking out the major irrigation (or sprinkler) manufacturers for their offerings.

- Q: Or could you put a blow off valve on a supercharger?

- No, superchargers make a whine, turbos make a spooling sound

- Q: I went to turn the water off with the shut-off valve so that I could do some work on the toilet tank (replacing old and leaky fill valve) but the water won't shut off. I'm assuming that I'll need to replace the shut-off valve itself but could anything else be causing the problem? The funny thing is, the leaky fill valve that I wanted to replace has now stopped hissing and leaking and the tank seemingly fills fine. But of course the water can't be turned off completely.Just wanted to check make sure that there aren't anything else I should do or consider before I went off to replace the shut-off valve.Thanks

- the shut off valves are soldiered on or threaded on it depends on which 1 you got. it might be easier to get a valve that looks like yours and putting the guts out of the new 1 into the old 1. as long as you can shut the water off to the valve

- Q: i have a 04 kia sadona i have been having issues with the van overheating someone told me to open the bleeder valve and let it drain then refill leave the valve open and if i see bubbles in the radiator than its a blown head gasket. is this true? is there a bleeder valve on this and if so where is it located? its not on the thermostat housing i allready replaced the thermostat.

- Yes it does have a bleeder valve, it should be on the side or in cooling hose, if your coolant has been low and you added you have air in the system, open bleeder valve till flow comes out smooth while engine is running and warm, when good flow is established and radiator is full close valve, should be good to go and will now be full and no more heating up.

- Q: Is there something else i can use to lubricate my trumpet valves besides valve oil....I don't have any at the moment but really need to lubricate the valves.

- I found vasaline worked if you're on a tight budget, but baby oil works better.

- Q: i hav no clue wat it is or what it does, but i was goin to buy an 08 mitsubishi lancer but then i read that the valve guides in mitsubishi engines wear out really fast and it causes some problems.what kinds of problems?how will this effect the car?Should i go ahead and buy the car?

- Actually, in case your automobile used to be an blameless bystander and acquired broken by way of a police chase, it's the town that are supposed to be billed. The town is liable for all damages precipitated by way of the police in pursuit of criminals.

- Q: how long do people usually live after mitral valve repair?

- From what i've got study having it repaired rather than replaced has a much greater helpful restoration consequence. The survival fee is in the mid ninety's % clever so curiously like an rather secure surgical operation. Hoping she has a rapid restoration.

Send your message to us

Hydraulic plate valve with high quality and best price from okorder.com

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords