Hydraulic plate valve from okorder.com with high quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

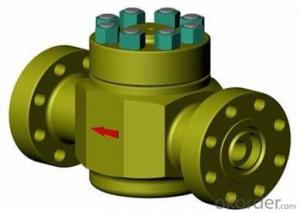

| Place of Origin: | China (Mainland) | Model Number: | Hydraulic plate valve | Brand Name: | sehm |

| Type: | Rotary Drilling Rig | Certification: | API | Usage: | Oil Well |

| Condition: | New | Warranty: | 1 | Voltage: | 2,000-15000 psi |

Specifications

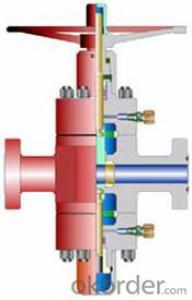

Hydraulic plate valve

SS Gate Valve Handwheel Operated

1.Medium: water, oil, gas.

2.Certificate:API 6D,TS,CE.

Hydraulic plate valve

Applicable standards:Steel gate valves, API 600 / API 6D

Steel gate valves, ISO 10434 / ISO 14313

Steel valves, ASME B16.34

Face to face, ASME B16.10

Flanges end, ASME B16.5

Buttwelding ends, ASME B16.25

Inspection and test, API 598 / API 6D

Design description:

Full port design

OS&y,outside screw and yoke

BB,Bolted bonnet

Flexible wedge,fully guided

Choice of solid or split wedge

Renewable seat rings

Forged T-head Stem

Rising stem and non-rising handwheel

Flanged or buttwelding ends

Available with BG operator

Gate Valve Product Details

Design and Manufacture | ANSI B16.34,API600,API603,BS1414 |

Face to face(end to end) | ANSI B16.10,API6D |

Flanged connection | 2"~24" TO ANSIB16.5,22",26"~36" TO MSS-SP-44 to API 605 on Request |

Test and inspection | API 598,API6D |

Butt welded end | ANSI B16.5 |

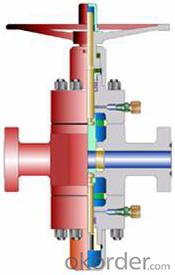

A. Anti-friction ball thrust bearing: Reduces friction between mating parts to ensure smooth operation

B. Grub screw: Secures yoke nut in the bonnet

C. Grease nipple: Supplies lubricant to the mating parts

Manufacturing Process

STANDAR3DISATION

All products are manufactured in accordance with the guidelines of International Standard accepted all over the world such as Manufacturers Standardisation Society (MSS), American Petroleum Institute (API), American Society of Mechanical Engineers (ASME), British Standard (BS), Bureau of Indian Standard (BIS).

PROCURMENT OF RAW MATERIAL

In the manufacturing process we require Castings of different grades, Stainless steel Bars, forgings, hardware, gaskets & paints. All raw material purchase from the reputed & genuine concerned supplier.

QUALITY CONTROL

All raw materials are checked by our Quality Assurance Department prior to manufacturing process. For an example, when we received the castings, it is checked visually and dimensionally for machining tolerance. We also check the foundry chemical Test Certificate and physical test certificate, compared to suitable international standard and passed to machining shop for the further process, if it is rejected it is send back to the supplier.

MACHINING

The raw material issued to the machine shop for the machining, is machined strictly as per the relevant drawings.

INPROCESS TESTING

If it is found OK dimensionally the valve body and bonnet are sent for the hydro testing. All internal parts such as seat, disc, stem are measured by the Vernier Caliper or micrometer, if it is found O K than pass to assembly section for the further assembly. All the valve body and bonnet are tested on the motorized pump or hand pump as per the relevant standard. The theory being, when the body or the bonnet is under pressure there should not be any leakage or drops of the testing fluid from any portion of the castings. If any leakage observed, it is rejected and sent back to the foundries.

ASSEMBLY

The body and bonnet, which are Hydrostatically O K, are sent to assembly section, duly handled with care to avoid the scratches on the machined surfaces. In the assembly section body and bonnet are drilled on drill machine with the help of jigs & fixtures for uniformity and interchangeability.

LAPPING

In metal to metal seated valves, seat & disc/plug are lapped by Rough Lapping Paste to smoothen the seating surface and than lapped with very fine grade lapping paste for the proper sealing of disc & seat surface, to ensure zero leakage.

TESTING

After assembly of new complete valve is sent for Hydrostatic Testing. If no leakage is found as per the relevant standard, it is sent to finishing section.

FINISING/PAINTING & PACKING

The valve body and bonnet is debarred and finished by flexible shaft grinders for better appearance. One coat of corrosion resistance primer (red oxide) is sprayed, and colored as per the codes, twice for superior surface look.

Valves are packed either in wooden boxes or Gunny bags duly protected by ends enclosures and soft material to avoid any damages during transit.

MainFeatures :

Body & Bonnet made from high quality casting with liberal sections. The castings are precision machined for high performance

Bi-Directional Shut-Off

Die moulded Graphite (Grafoil) Packing Rings, controlled clearance between stem, gland and bonnet bushing for guaranteed low emissions and also suitable for higher temperature.

Deep stuffing box is providing for tightness and maximum long packing life.

Swinging Eye Bolts facilitate easy access to the stuffing box.

Back seating feature facilitates repacking of the stuffing box on line with the valve in fully open position.

Seat Ring Screwed in to the body are replaceable type. Seal welded type Seat Ring & Integral Seat cab also be offered on special request.

Stellited Disc, Seat Ring & Back Seat can also be offered on special request.

Higher Pressure & Higher Size Valves are provided with Thrust Bearings and also with Gear drive arrangements.

In built wear life for long duration of service.

- Q: what is the difference between mitral valve prolapes and mitral regurgitation?

- Mitral valve prolapse refers to a condition in which the leaflets of the valve are large and floppy compared to the average. When the ventricle contracts, the valve closes and the flow causes a pop as the floppy leaflet fills with blood, much like the way the wind fills a sail. This extra pop can be heard with a stethoscope (like a click) but it can often be felt by the person affected which makes them more aware of their heartbeat than the rest of us. Mitral Valve regurgitation is a condition in which the mitral valve leaks after it is closed leading to a loss of efficiency of blood pumping and a drop in blood pressure. It is often a small leak and is of little consequence and is often associated with mitral valve prolapse. This leak can sometimes be heard with a stethoscope as a murmur under the left arm. The combination of both situations is known as Barlow's click-murmur syndrome. Old Doc

- Q: We have an oil steam system. There are Dole valves - 1A on each of the radiators. We bought new ones. They don't seem to be working. They look like a bullet shape with a screw in (on the side of the bullet) to the radiator. On the top of the bullet is a slit with numbers 1-10 on a dial. A picture we saw on the web showed a plastic piece of tubing in the screw part which looks like it goes into the radiator. If we remove the valve, the radiator gets hot with steam coming out of the hole. With the new valve on, the radiator barely gets warm. We're in Piscataway, NJ 08854. H-E-L-P.

- Seems to me that a steam valve would need to hold a lot more pressure than a hot water valve. Steam is a high pressure gas and water is a liquid irregardless how hot it is (below boiling point) I am not a qualified plumber or boiler tech but personally I wouldn't use a steam valve for water or vise versa.

- Q: How do you repack an osy valve? Where do you get the packing from? Do you have to shut down the water to do it?

- For most valves, replacing the packing can be done without shutting down the water system. The first step is to back seat the valve. Back seating will occur when the valve is fully opened, and will temporarily seal the leak around the stem. You simply open the valve completely with about 50-100ft-lb of pressure. Once the leaking has stopped, you can remove the packing bolts and nuts on the packing gland. Slide the packing gland up the stem and you will have access to the packing. You may need a packing hook, which is a flexible corkscrew tool, to help remove the old packing. Once you have removed the old packing you will want to repack the valve with new packing by wrapping it around the stem and pushing it down into the valve body. After the new packing has been replaced, it may need to be compressed a little so that the packing gland can be reinstalled. This can be done using two pieces of all-thread rod. Cut both all-thread rods to 6 inches long, making sure to use the same diameter all-thread rod as your packing bolts. Place the all-thread rod through the packing gland and tighten the nuts onto the all-thread rod to compact the packing in the valve. Next, remove the all-thread rod and replace with the bolts. Turn the hand wheel, so the valve is about half way open. Finally, tighten the nuts evenly until all leakage around the stem stops. You may need to exercise the valve a few times to make sure there are no leaks around the stem. Be careful not to over tighten the gland because it can crack and there is no reason to compress the packing more than is needed to stop the leak.

- Q: What's the safety valve (relief valve) type?

- The four common types of pressure relief are the spring loaded valve, the rupture disc, the balance bellows spring loaded valve and the pilot operated relief valve.

- Q: Ok. I have to ask cause I have been in hospital all weekend after having a moment on saturday when my heart decided to start racing. Woke up 4.30am on saturday morning cause of blood test which kinda showed I could have had a heart attack which was scarey and though I was discharged today I got told I had a leaking aortic valve. What does this mean and what is going to happen. I am honestly really worried cause it cant be good

- It just means that one of the valves in your heart doesn't completely close. So when your heart pumps blood it doesn't do it as effectively. I have a leaky mitral valve and I have no symptoms. I just have to take antibiotics anytime I have dental work done. Bacteria from your mouth like to mess up your valves if they are already leaky. But it almost never happens. It's just a precaution. You really need to talk to your doctor about what he found. He needs to explain whether it's serious or nothing to be worried about.

- Q: Beneath my kitchen sink are two shut off valves for the water; one for hot, one for cold. The hot water valve has never successfully stopped all water flow, so we've always resorted to shutting off the main line. Well, now that's not working. We shut off the main water line to the house, all water everywhere is non-functioning except for the hot water pipe beneath my sink. It's now causing the faucet to constantly stream water, so it's something we have to resolve ASAP. I'd like to avoid calling a plumber, but my knowledge in such areas is very limited. Can anyone give me any decent suggestions? For the record, I did take apart the faucet fixture just in case, thoroughly cleaned it, and replaced all of the washers I had access to; but we only just bought the faucet in September, so I can't see a worn washer as being the problem. I also tried to tighten the nut behind the handle on the valve. It didn't effect the dripping.

- Leaky Water Valve

- Q: Its stuck to an angle where the metal parts of the wheel block the air pump from letting it secure itself around the valve so i cant put air in, it all comes out the sides, i dont want to have to replace anything for i dont know much about bikes, but any solution to my problem? Thanks

- Let all the air out of the tube and you will be able to move the tire and tube around so that you can move to where the valve stem is poking directly out of the rim opening. Then fill it with air again. There are videos on YouTube that show how to change a tube. Watch some of those and I'm sure you will see somebody do this.

- Q: Hi, in the heart, blood flows through the AV valves and enters the ventricles once the atria have filled up with blood. What opens the AV valves? Fluid pressure from the blood or the SA node pulses?

- The opening and closing of the atrioventricular valves is controlled by the differences in pressure across them: When blood passes from an atrium to a ventricle, the atrioventricular valve is pushed open (and the papillary muscles relax and the chordae tendineae lose their tension, becoming slack). At the next stage in the sequence the ventricle contracts. This forces blood out from the ventricle into the artery via which it leaves the heart. This contraction of the ventricle and the corresponding increase in blood pressure within that ventricle also presses the cusps of the atrioventricular valve together until their edges meet, closing the valve. At the same time, the papillary muscles contract and the chordae tendineae tighten - both of which also help to prevent the cusps from enabling the atrioventricular valves to open. When in the next stage of the sequence the ventricle relaxes and the atrium contracts, the blood pressure situation is reversed, the relaxation/tension of the papillary muscles and the chordae tendineae also reverses, and the atrioventricular valve allows blood to pass from the atrium to the ventricle again.

- Q: This trumpet has been in storage in its casing untouched for about 5 years. I took it out and tried to play it but only air comes out and no sound. The 2nd and 3rd valves are hard to push down. What do I do to fix it? Thanks!

- take the valves out and lightly apply some vegetable oil to free them up.

- Q: as we are strating centrifugal pump with discharge valve close and can not start positive displacement comp. with disch. valve closed

- No, with no discharge flow, there's no suction flow the compressor will immediatley go into surge. However, if a Low-Flow recycle control is installed, upstream of the discharge valve (which should recycle back to the suction drum to prevent heat build-up), then the compressor will operate without surging and without lifting the discharge safety valve but the condition should be corrected ASAP. (A Centrifugal Compressor will normally be fitted with a Low flow recycle system taken off from the aftercooler discharge line for use during start-up but, if a sudden low flow condition occurs and the recycle doesn't have time to activate, a Low Flow alarm and trip system will shut down the machine). Also, starting a centrifugal pump against a closed discharge is quite common practice as long as it too has a low flow protection recycle back to the suction vessel. This Low flow recycle is common where the discharge has a liquid level or flow control valve installed and may close down during normal operation. This valve would be operating as a 'Split System' controller in conjunction with the Low-Flow recycle control valve. PD pumps without discharge pressure safety protection should NEVER be started against a closed discharge, the hydraulic pressure build up will be instantaneous with possible disastrous results or stalling of the pump.

Send your message to us

Hydraulic plate valve from okorder.com with high quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords