Hot Sell EPDM Waterproofing Membrane Factory Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

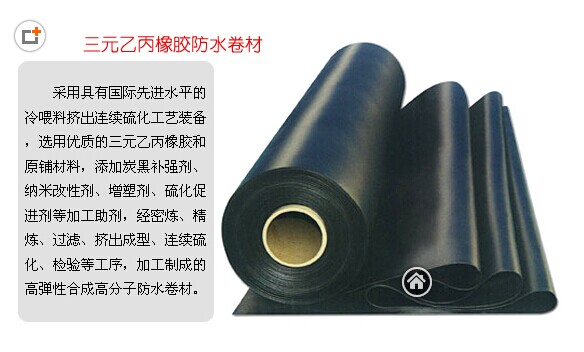

EPDM waterproofing Rubber membrane

1. Introduction of EPDM Waterproofing Membrane:

EPDM Waterproofing Membrane is the modified materials which is widely used at home and abroad in the kinds of roofs, tunnel, basement such sorts of constructions' waterproofing.

They are based upon EPDM rubber with modifier, softener and accelerant assistants added to provide flexibility and stability . Through the precise ingredients, mixing, extrusion, rolling, curing processes to made of modified EPDM Waterproofing material with high strength and high flexibility.

2. Specification of EPDM Waterproofing Membrane:

Type | EPDM Waterproof Membrane | ||

Material | EPDM Rubber | ||

Thickness | 1.2mm | 1.5mm | 2.0mm |

Weight(kg/m2) | 1.54-1.58 | 1.79-1.83 | 2.25-2.29 |

Size | 1.2m(width) * 20m(length)/roll | ||

Type | Vulcanized & Weldable | ||

Pattern | Non-reinforced(homogeneous) | ||

Packing | 24sqm/roll, with plastic bag | ||

Color | Black | ||

Application | Roof, basement, pond, Lake, steel structure roof, swimming pool, underground, tunnel, etc | ||

3. Product Features of EPDM Waterproofing Membrane:

1. Great tensile strength,long-range elasticity and aging resistant.

2. Excellent heat reisistant and can be used under -70°C~~+110°C .

3.Good anti-corrosion, ultraviolet resistant, root penetration resistance

4.Long life use over 50 years and used longer 100 years or more under the condition of buried in the ground.

5.Light and easy to install.

4. Application of EPDM Waterproofing Membrane:

(1) Roofs, Basement, Toilets

(2) Industrial and civil building waterproofing

(3) Geosynthetic liner for swimming pool, channels, irrigation system

(4) Especially suitable for projects with high requirements in durability, anti-corrosion and deformation

4. Some photos:

- Q: Can a waterproofing membrane be used on glass surfaces?

- No, a waterproofing membrane cannot be used on glass surfaces.

- Q: Can a waterproofing membrane be used for historic preservation projects?

- Yes, a waterproofing membrane can be used for historic preservation projects. Historic buildings often require special attention to preserve their original architecture and materials. Waterproofing membranes can be applied to protect historic structures from water damage, which can lead to deterioration and decay. These membranes are designed to be flexible, durable, and long-lasting, making them suitable for use on historic buildings. They can be applied to roofs, walls, and foundations to prevent water infiltration and ensure the preservation of the building's structural integrity. However, it is important to consult with preservation experts and adhere to appropriate preservation guidelines to ensure that the use of a waterproofing membrane is compatible with the building's historical significance and does not compromise its authenticity.

- Q: Can a waterproofing membrane be used for roofs with foot traffic?

- Indeed, it is possible to utilize a waterproofing membrane for roofs that experience foot traffic. Nevertheless, it is imperative to select a membrane that is specifically engineered and classified for foot traffic. Usually, these membranes incorporate sturdier materials like reinforced PVC or modified bitumen, enabling them to endure the constant wear and tear resulting from regular foot traffic. Moreover, it is of utmost importance to guarantee the proper installation and maintenance of the membrane, so as to avert any potential harm or leakage that may undermine its waterproofing capacity. Consistent inspections and essential repairs must be conducted to guarantee the long-lasting and efficient performance of the membrane.

- Q: Can a waterproofing membrane be used on tunnels with architectural features?

- Yes, a waterproofing membrane can be used on tunnels with architectural features. The membrane can be applied to various surfaces, including those with architectural features, to provide effective waterproofing and prevent water infiltration. This ensures the protection of the tunnel structure and helps maintain its integrity.

- Q: Can a waterproofing membrane be used for a hospital?

- Yes, a waterproofing membrane can be used for a hospital. Waterproofing membranes are commonly used in construction projects to prevent moisture infiltration and protect the integrity of the building materials. In a hospital setting, where hygiene and infection control are of utmost importance, it is crucial to maintain a dry and clean environment to prevent the growth of mold, mildew, and bacteria. A waterproofing membrane can help to create a barrier against water and moisture, preventing any potential damage to the structure and ensuring a safe and healthy environment for patients, staff, and visitors. Additionally, waterproofing membranes can also be used in specific areas of a hospital, such as operating rooms or laboratories, where the risk of spills or water exposure is higher. Overall, the use of a waterproofing membrane in a hospital can contribute to maintaining a high standard of cleanliness, safety, and durability in the facility.

- Q: Sbs modified asphalt waterproof membrane polyester type Ⅰ type Ⅱ how to distinguish

- SBS modified asphalt waterproofing membrane is SBS rubber modified petroleum asphalt cited as the invasion coating, polyester fiber non-woven fabrics, jute cloth, fiberglass mats were made for the fetal base, the plastic film for the anti-sticking isolation Layer, by the selection, ingredients, eutectic, invasion, composite molding, curling and other processes processing production.

- Q: Is a waterproofing membrane resistant to abrasion?

- Yes, a waterproofing membrane is generally designed to be resistant to abrasion. The membrane is typically made of durable materials that can withstand friction and wear, ensuring long-lasting protection against water damage.

- Q: Can a waterproofing membrane be used in conjunction with flooring materials?

- Indeed, flooring materials can be used in conjunction with a waterproofing membrane. It is actually quite common to advise the application of a waterproofing membrane while installing specific types of flooring, particularly in wet spaces such as bathrooms, kitchens, or basements. The waterproofing membrane functions as a shield against moisture, effectively thwarting water penetration that could potentially harm the flooring material or the subfloor. It provides safeguard against leaks, spills, and even excessive moisture in the atmosphere. Through the utilization of a waterproofing membrane, you can guarantee the longevity and sturdiness of your flooring, simultaneously upholding a waterproof and moisture-resistant environment.

- Q: What are the different thickness options for a waterproofing membrane?

- Waterproofing membranes are available in a range of thicknesses to accommodate different needs and uses. Typically, the thickness of a waterproofing membrane can vary from 0.5 mm to 2.0 mm. For applications that require a flexible and lightweight solution, thinner waterproofing membranes, measuring between 0.5 mm and 0.8 mm, are often utilized. These membranes are commonly employed in residential waterproofing projects, such as roof decks, balconies, and basements. Additionally, they are suitable for areas with minimal foot traffic or limited space, as their thin profile allows for easy installation and minimal disruption to the existing structure. In both residential and commercial applications, medium-thickness waterproofing membranes, ranging from 1.0 mm to 1.5 mm, are frequently used. These membranes offer a balance between flexibility and durability, making them appropriate for areas that may experience moderate to heavy foot traffic or require additional protection. Common areas of application include shower enclosures, wet rooms, and exterior walls. Thicker waterproofing membranes, typically measuring 1.5 mm to 2.0 mm, are often preferred for high-demand applications or areas exposed to extreme conditions. These membranes provide enhanced strength, resilience, and resistance to punctures and abrasions. They are commonly utilized in industrial settings, commercial buildings, and civil engineering projects, such as tunnels, bridges, and parking structures. It is important to note that the appropriate thickness option for a waterproofing membrane depends on specific project requirements, including anticipated usage, exposure to moisture, and expected loads. Therefore, it is advisable to consult with a professional or manufacturer to determine the most suitable thickness option for a particular application.

- Q: Can a waterproofing membrane be used on plastic block surfaces?

- Yes, a waterproofing membrane can be used on plastic block surfaces. These membranes are designed to provide a protective barrier against moisture, preventing water from seeping through the surface. Plastic blocks, like any other surface, can be susceptible to water damage if not properly protected. Applying a waterproofing membrane can help seal and protect the plastic blocks, preventing water penetration and potential damage. It is important to choose a waterproofing membrane that is compatible with plastic materials and follow the manufacturer's instructions for application to ensure the best results.

Send your message to us

Hot Sell EPDM Waterproofing Membrane Factory Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords