Black EPDM Waterproofing Membrane Factory Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

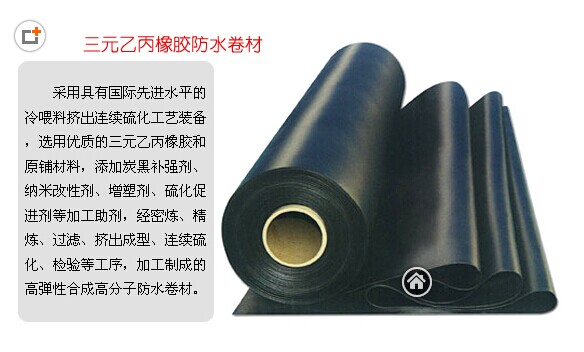

This waterproof coiled material is of high elasticity with best performance among high polumer

waterproof coiled material in the world.It is also the most typical one in the world.Waterproof coiled material made of ternary ethylene-propylene rubber is produced withthe use of the most advanced contiuous extrusion and vulcanization technology and related equipments which are specially designed for production of such product.It is good in compactness,without bubble and performance difference in length and breadth,perfomances reach or exceedthe demands of GB18173.1-2000 standard.

Features

Excellent antiaging performance, service life up to 50 years

Working well with in 40C to 100C,it canbe constructed with a single layer in ambient temperature.

Waterproofing on various kinds of underground project,industrial of civil buildings and structures.

high extension rate, high tensile strength, small size changes at heat treatment

Good plant roots penetrability resistance and can be made waterproofing layer of planting roof

Special modified molecular structure ,effectively resolving the current domestic and foreign glue joint problem .

Good low temperature flexibility, and good performance of adapting to ambient temperature changes.

Convenient application ,solid joint, no environment pollution

chemical corrosion Resistance, can be used for special occasions

Convenient maitenance, low cost.

Specifications

Type | EPDM Waterproof Membrane | ||

Material | EPDM Rubber | ||

Thickness | 1.2mm | 1.5mm | 2.0mm |

Weight(kg/m2) | 1.54-1.58 | 1.79-1.83 | 2.25-2.29 |

Size | 1.2m(width) * 20m(length)/roll | ||

Type | Vulcanized & Weldable | ||

Pattern | Non-reinforced(homogeneous) | ||

Packing | 24sqm/roll, with plastic bag | ||

Color | Black | ||

Application | Roof, basement, pond, Lake, steel structure roof, swimming pool, underground, tunnel, etc | ||

Application

(1) Roofs, Basement, Toilets

(2) Industrial and civil building waterproofing

(3) Geosynthetic liner for swimming pool, channels, irrigation system

(4) Especially suitable for projects with high requirements in durability, anti-corrosion and deformation

4. Some photos:

- Q: Can a waterproofing membrane be used for a bridge deck construction?

- Yes, a waterproofing membrane can be used for bridge deck construction. Waterproofing membranes are commonly used in bridge deck construction to protect the underlying structure from water infiltration, which can cause corrosion and damage over time. The membrane acts as a barrier to prevent water from seeping into the concrete, ensuring the durability and longevity of the bridge deck.

- Q: Can a waterproofing membrane be used on precast glass surfaces?

- Yes, a waterproofing membrane can be used on precast glass surfaces. Precast glass surfaces typically have joints and seams where water can penetrate, so applying a waterproofing membrane can help to create a barrier against water infiltration. The waterproofing membrane will help to prevent water from seeping into the joints and causing damage to the precast glass. It is important to choose a waterproofing membrane that is specifically designed for use on glass surfaces and follow the manufacturer's instructions for proper application. Additionally, regular maintenance and inspections should be conducted to ensure the continued effectiveness of the waterproofing membrane.

- Q: Are waterproofing membranes suitable for underground parking garages?

- Yes, waterproofing membranes are suitable for underground parking garages. Underground parking garages are constantly exposed to groundwater and moisture, which can lead to water infiltration and damage to the structure. Waterproofing membranes provide an effective solution to prevent water penetration and protect the concrete structure from deterioration. Waterproofing membranes are designed to create a barrier against water and moisture, preventing them from entering the garage. These membranes are typically applied to the exterior walls, foundation, and floor slab of the parking garage. They are made of durable materials such as modified bitumen, polyurethane, or rubberized asphalt, which can withstand the harsh conditions of underground environments. By installing waterproofing membranes in underground parking garages, the risk of water damage, such as concrete cracking, corrosion of reinforcement steel, and mold growth, is significantly reduced. The membranes act as a protective layer, ensuring the longevity and structural integrity of the parking garage. Furthermore, waterproofing membranes can also help in minimizing the potential for vapor transmission, which can lead to condensation and humidity issues inside the parking garage. This is especially important for underground parking garages located in regions with high water tables or areas prone to heavy rainfall. Overall, waterproofing membranes are an essential component in the construction or renovation of underground parking garages. They provide a reliable and long-lasting solution to protect the structure from water infiltration, ensuring the safety and durability of the parking facility.

- Q: Are waterproofing membranes resistant to impact damage?

- Yes, waterproofing membranes are generally designed to be resistant to impact damage. They are often made with durable materials such as PVC or TPO that can withstand moderate impacts without compromising their waterproofing capabilities. However, the level of impact resistance may vary depending on the specific type and quality of the membrane.

- Q: Can a waterproofing membrane be used on precast nickel surfaces?

- Precast nickel surfaces can indeed benefit from the application of a waterproofing membrane. These membranes are specifically designed to create a barrier against moisture and thwart water infiltration. They can be effectively utilized on a variety of surfaces, such as concrete, metal, and even nickel. Nevertheless, it is crucial to ascertain that the waterproofing membrane is appropriate for use on nickel surfaces and is compatible with the particular type of precast nickel in question. To obtain guidance on the specific application and guarantee proper adhesion and effectiveness of the membrane on precast nickel surfaces, it is advisable to consult a professional waterproofing contractor or reach out to the manufacturer of the membrane.

- Q: Does a waterproofing membrane provide any UV resistance?

- Yes, a waterproofing membrane can provide some level of UV resistance. Many waterproofing membranes are designed to withstand exposure to sunlight and UV rays, which can cause degradation and damage over time. These membranes are often formulated with UV stabilizers or additives that help protect against UV radiation, prolonging their lifespan and maintaining their effectiveness in providing waterproofing protection. However, the level of UV resistance may vary depending on the specific type and quality of the waterproofing membrane.

- Q: Do waterproofing membranes require maintenance?

- Yes, waterproofing membranes do require maintenance. Regular inspection and maintenance are necessary to ensure the effectiveness and longevity of the waterproofing system. This may include checking for any damages or wear and tear, clearing debris, ensuring proper drainage, and addressing any potential issues promptly.

- Q: How does a waterproofing membrane withstand temperature changes?

- A waterproofing membrane is designed to withstand temperature changes due to its material composition and structural properties. The membrane is typically made of a flexible and durable material, such as modified bitumen, EPDM (ethylene propylene diene monomer), PVC (polyvinyl chloride), or TPO (thermoplastic olefin). These materials have inherent properties that allow them to expand and contract with temperature variations, ensuring the membrane remains intact and effective. The membrane's flexibility is crucial in accommodating temperature changes. When exposed to heat, the membrane expands to prevent cracking or splitting. Conversely, in colder temperatures, the membrane contracts to maintain its integrity and prevent any gaps from forming. This flexibility also helps to absorb any movement or stress caused by thermal expansion and contraction, preventing damage to the waterproofing system. Additionally, the membrane's composition often includes additives that enhance its resistance to temperature changes. These additives can include UV stabilizers, which protect the membrane from the damaging effects of sunlight, and thermal stabilizers, which help to maintain the membrane's integrity and performance in extreme temperatures. Furthermore, the installation techniques used for waterproofing membranes also play a vital role in their ability to withstand temperature changes. Proper installation methods, such as allowing for sufficient overlap and securely sealing all joints and seams, help to create a continuous and robust barrier against water infiltration. This ensures that the membrane remains effective even when subjected to temperature fluctuations. Overall, a waterproofing membrane is specifically engineered to withstand temperature changes by utilizing flexible and durable materials, incorporating additives to enhance its resistance, and employing proper installation techniques. These factors allow the membrane to adapt to varying temperature conditions, maintaining its integrity and providing long-lasting protection against water intrusion.

- Q: Can a waterproofing membrane be used on precast aluminum surfaces?

- Indeed, precast aluminum surfaces can be effectively protected by utilizing a waterproofing membrane. These membranes are specifically engineered to safeguard various surfaces, encompassing concrete, metal, and other materials, against water infiltration. By acting as a formidable barrier, the membrane effectively thwarts the ingress of water into the precast aluminum surface. This proves to be especially advantageous in locales with elevated moisture exposure, such as surrounding swimming pools or outdoor environments. It is crucial to select a waterproofing membrane that is aluminum-compatible in order to guarantee optimal adhesion and long-lasting efficacy.

- Q: Does a waterproofing membrane prevent water damage to building materials?

- A waterproofing membrane is specifically designed to shield building materials from water damage. Its purpose is to act as a barrier, preventing water from infiltrating the structure and causing harm. Typically, the membrane is applied to areas prone to water intrusion, such as roofs, basements, and foundations. By creating a watertight seal, it effectively stops water from seeping through and harming the building materials. This safeguard is essential in maintaining the structure's integrity and preventing issues like mold growth, rot, and material decay. However, it's crucial to acknowledge that the effectiveness of a waterproofing membrane can vary based on the product's quality and proper installation. Regular maintenance and inspections are also necessary to ensure the membrane remains intact and continues to safeguard against water damage.

Send your message to us

Black EPDM Waterproofing Membrane Factory Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords