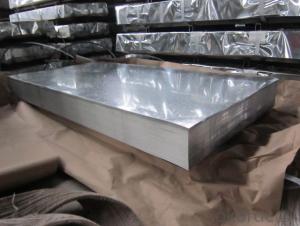

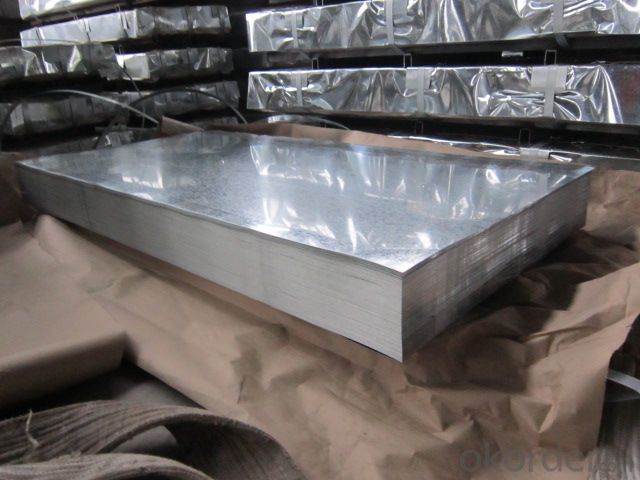

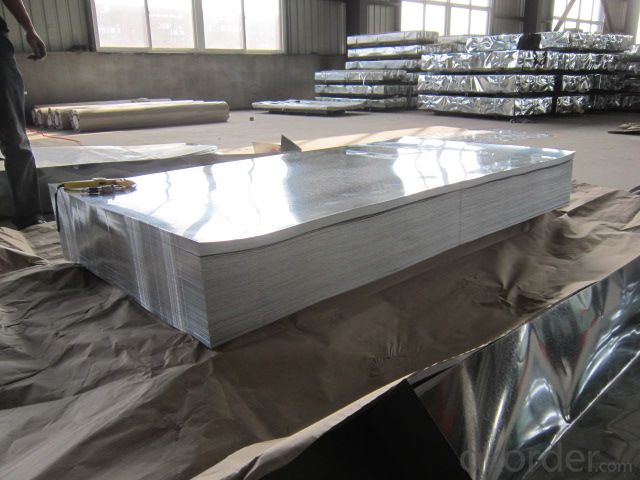

Hot-dipped-Galvanized Steel Sheet in Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

The most external layer is all zinc, but successive layers are a mixture of zinc and iron, with an interior of pure steel. These multiple layers are responsible for the amazing property of the metal to withstand corrosion-inducing circumstances. Zinc also protects the steel by acting as a "sacrificial layer." If rust does take hold on the surface of Galvanized Steel Coil, the zinc will get corroded first. This allows the zinc that is spread over the breach or scratch to prevent rust from reaching the steel.

Architecture Roofs and outside walls of civilian and industrial buildings, garage doors, fencings and window blinds.

1. Good Resistance to Corrosion

2. Qualified Processing Machinability

3. High Thermal Resistance

4. Excellent Reflectivity

Application:

Construction, packaging, railway vehicles, agricultural machinery and daily life.

Oiled/dry, Skin-pass/Nonskin-pass, Regular/Minimize/Zero Spangle

For countless outdoor, marine, or industrial applications, Galvanized Steel Coil is an essential fabrication component.

Architecture Roofs and outside walls of civilian and industrial buildings, garage doors, fencings and window blinds.

Appliances Industry Outer clad sheets for washing machine, refrigerator, television, air conditioner and ventilation system, explosion-proof strip, solar water heater and appliance parts.

Product Specification:

Base sheet : galvanized steel sheet, pre painted galvanized steel sheet

Zinc:40G-275G

Thickness:0.12mm-3.2mm

Width:600mm-1500mm

Length:1000mm-11800mm or as request

Package:Standard seaworthy export packing: 3 layers of packing, inside is kraft paper,water plastic film is in the middle and outside GI steel sheet to be covered by steel strips with lock.

FAQ:

1.How many pieces for one ton of the Hot-dip Galvanized Steel Sheet?

The pieces for one tone is decided by the thickness of the sheet, but we can make it according to your requirements in the reasonable range.

2. Do you have pallets for the package?

Yes, we must use pallets for the package in order to load.

3. How many tons do you load in one 20’FCL?

- Q: Are steel sheets available in textured finishes?

- Steel sheets are indeed available with textured finishes. Various processes, such as embossing, etching, or brushing, can be used to achieve these textured finishes. These techniques create patterns or textures on the surface of the steel sheet, resulting in a distinctive and visually pleasing appearance. In addition to enhancing the aesthetic appeal, these textured finishes offer functional advantages, such as improved grip, reduced glare, and increased durability. Depending on the specific application and design preferences, different types of textures can be applied to steel sheets.

- Q: What are the insulation properties of steel sheets?

- Steel sheets have limited insulation properties as they are strong conductors of heat and electricity. However, their high thermal mass allows them to absorb and slowly release heat, which can provide some degree of insulation. To enhance insulation, steel sheets can be combined with other insulating materials or used in conjunction with insulation systems.

- Q: What is the process of galvalume coating on steel sheets?

- The process of galvalume coating on steel sheets involves the application of a zinc-aluminum alloy coating to protect the steel from corrosion. This is typically done through a continuous hot-dip process where the steel sheet is passed through a bath of molten zinc-aluminum alloy. The sheet is then cooled and solidified, resulting in a durable and corrosion-resistant coating on the surface.

- Q: How do steel sheets handle impact resistance?

- Steel sheets are known for their exceptional impact resistance. Due to their high strength and toughness, steel sheets can effectively absorb and distribute the energy produced by an impact, minimizing the damage caused. This is primarily attributed to the microstructure of steel, which consists of a crystalline lattice that allows for the deformation and reformation of the material under stress. When subjected to an impact, steel sheets undergo plastic deformation, which enables them to absorb the energy and prevent it from propagating further. The ability of steel sheets to handle impact resistance is further enhanced by their composition, which often includes alloying elements such as manganese, chromium, and nickel. These elements increase the hardness and strength of the steel, making it even more resistant to deformation and fracture. As a result, steel sheets are widely used in various applications where impact resistance is crucial, including automotive manufacturing, construction, and heavy machinery industries.

- Q: What is the maximum width of a steel sheet?

- The maximum width of a steel sheet can vary depending on various factors such as the manufacturing process, equipment capabilities, and industry standards. In general, steel sheets can be produced in widths ranging from a few inches to several feet. However, in certain specialized applications, wider steel sheets exceeding 100 inches or more may be available. It is best to consult with steel manufacturers or suppliers to determine the maximum width options they offer, as it can vary depending on the specific requirements and capabilities of the production facility.

- Q: Are steel sheets suitable for magnetic shielding?

- Yes, steel sheets are suitable for magnetic shielding. Steel is a highly magnetically conductive material, which makes it effective at redirecting and absorbing magnetic fields. It can be used to create barriers that prevent magnetic fields from penetrating or escaping certain areas, making it an ideal choice for magnetic shielding applications.

- Q: What is the typical flexural strength of a steel sheet?

- The typical flexural strength of a steel sheet can vary depending on its grade and thickness. However, most commonly used steel sheets have a flexural strength ranging from 250 to 500 megapascals (MPa).

- Q: Can steel sheets be used in the telecommunications industry?

- Yes, steel sheets can be used in the telecommunications industry. Steel sheets are commonly used for various applications in the telecommunications industry due to their strength, durability, and ability to protect sensitive equipment. They are often used to manufacture communication towers, antenna mounts, equipment cabinets, and enclosures. Steel sheets provide structural support and can withstand harsh environmental conditions such as strong winds, extreme temperatures, and heavy loads. Additionally, steel sheets can be easily fabricated and customized to meet specific requirements, making them a popular choice in the telecommunications industry.

- Q: How do you calculate the square footage of a ton of steel?

- The weight of the steel plate is 7.85 tons / cubic meter.The area of 1 ton steel plate (thickness 0.5mm) is: steel plate weight / (steel plate weight * steel plate thickness) =1000/ (7.85*0.5) =254.78 square metersThe total number of steel sheets of 1 tons 1500mm*1800mm*0.5mm specification is 254.78/ (1.5*1.8) =94.36 sheets1500mm*1800mm*0.5mm specification steel plate, each weight is 1.5*1.8*7.85*0.5=10.6 kg

- Q: What is the difference between a smooth and diamond plate steel sheet?

- Smooth steel sheets are sheets of steel that have a flat, even surface, devoid of any raised patterns or textures. They are typically manufactured by rolling and smoothing the steel to achieve a uniform look. These sheets are commonly utilized in applications where a clean, polished appearance is desired, such as in architectural projects or for decorative purposes. On the contrary, diamond plate steel sheets, also known as tread plate or checker plate, possess a raised pattern of diamonds or lines embossed on their surface. This pattern not only adds visual appeal but also offers improved traction and grip, making it ideal for scenarios that necessitate slip resistance or protection against slipping hazards. Diamond plate steel sheets find frequent use in industrial settings, such as on ramps, stairs, or walkways, where increased safety and stability are required. In terms of functionality, the primary distinction between smooth and diamond plate steel sheets lies in their surface texture and the specific purposes they serve. While smooth steel sheets prioritize a sleek appearance, diamond plate steel sheets prioritize functionality and safety.

Send your message to us

Hot-dipped-Galvanized Steel Sheet in Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords